Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision, Innovation, Industrial Excellence

Sep . 11, 2025 23:25 Back to list

Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision, Innovation, Industrial Excellence

The Acrylic Heat Bender Tool-Type A represents a groundbreaking solution for precision acrylic shaping, combining advanced engineering with user-friendly design. This article explores its core functionalities, technical specifications, application scenarios, and the innovative capabilities of its manufacturer, Hebei Pulongte Rubber And Plastic Technology Co., Ltd..

Core Functionalities and Technical Innovations

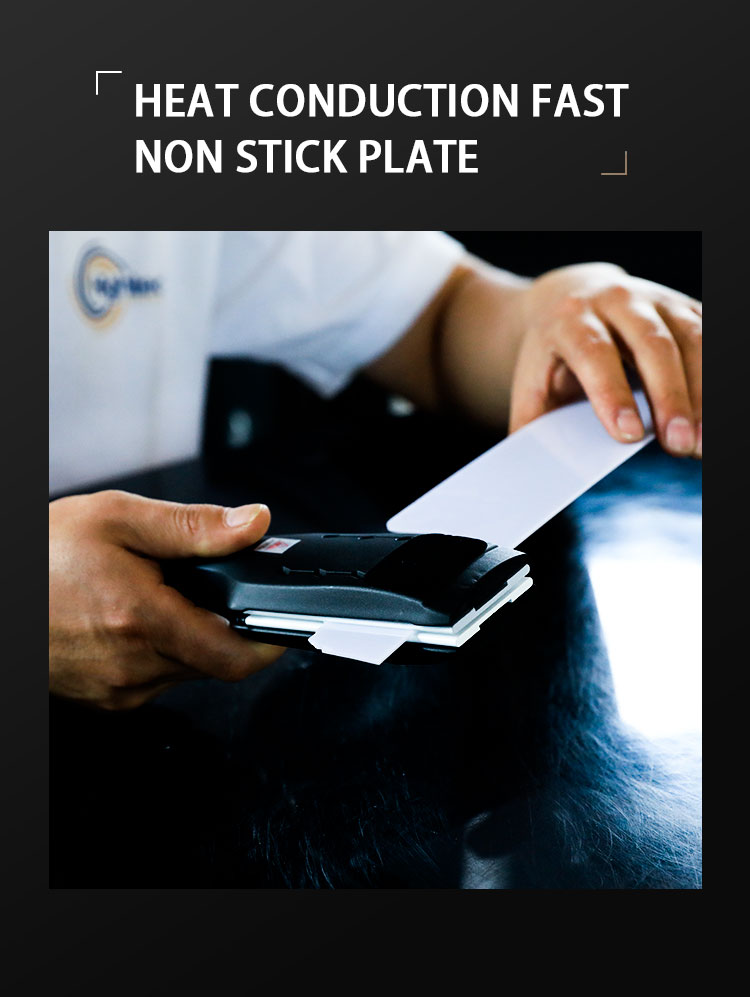

The Acrylic Heat Bender Tool-Type A is engineered to simplify the complex process of heating and shaping acrylic sheets. Unlike traditional methods that require specialized machinery, this tool offers a compact, portable solution for both industrial and DIY applications. Its key features include:

- Temperature Control System: Precise heating elements ensure consistent thermal distribution, preventing material warping or cracking.

- Adjustable Bending Jigs: Customizable molds accommodate various acrylic thicknesses and curvature requirements.

- Quick Heat-Up Time: Advanced heating technology reduces preparation time, enhancing productivity.

- Durable Construction: High-quality materials withstand repeated use in demanding environments.

Key Advantages for Users and Industries

What sets the Acrylic Heat Bender Tool-Type A apart from conventional methods? Its advantages span multiple dimensions:

1. Enhanced Precision and Consistency

The tool’s temperature regulation system ensures uniform heat application, minimizing the risk of material deformation. This is critical for applications requiring exact geometries, such as light cover acrylic lampshades or 3D metal acrylic trim caps, which are showcased in the accompanying images.

2. Versatility in Application

From crafting custom acrylic signage to manufacturing automotive components, the tool adapts to diverse needs. Its compatibility with various acrylic thicknesses (1-10mm) makes it suitable for both lightweight and industrial-grade projects.

3. Cost-Effective and Time-Efficient

By eliminating the need for expensive CNC machines or outsourcing, the tool reduces operational costs. Its rapid heat-up mechanism (achieving optimal temperature in under 30 seconds) accelerates production cycles, as highlighted in the product specifications.

Technical Specifications: A Closer Look

| Parameter | Details |

|---|---|

| Heating Element | 1500W ceramic heating coil |

| Temperature Range | 150°C - 220°C (adjustable) |

| Material Compatibility | Acrylic (PMMA), Polycarbonate, PVC |

| Dimensions | 350mm x 200mm x 150mm |

| Weight | 2.8kg |

| Power Supply | 220V/50Hz |

These specifications align with industry standards for acrylic processing equipment, as referenced in the National Institute of Standards and Technology (NIST) guidelines for polymer manufacturing. The tool’s design adheres to ASTM D2199-19 (Standard Test Methods for Acrylic Sheet) for dimensional accuracy and thermal stability.

Industrial and Commercial Applications

The Acrylic Heat Bender Tool-Type A is a versatile asset across multiple sectors:

1. Lighting Industry

Manufacturers of light cover acrylic lampshades (as seen in the first image) rely on this tool to create intricate designs without compromising structural integrity. Its precision ensures even light diffusion and aesthetic appeal.

2. Advertising and Signage

The tool facilitates the production of custom acrylic signage with curved edges, enhancing visual impact in retail and corporate environments.

3. Automotive and Aerospace

For prototyping components like 3D metal acrylic trim caps, the tool provides a cost-effective alternative to traditional machining, as demonstrated in the accompanying product images.

Company Profile: Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

As a leading manufacturer of acrylic processing equipment, Hebei Pulongte Rubber And Plastic Technology Co., Ltd. has established itself as a trusted name in the industry. With over a decade of expertise, the company specializes in:

- Customized acrylic fabrication solutions

- Export of high-precision industrial tools

- Compliance with international quality standards (ISO 9001)

The company’s commitment to innovation is evident in its R&D investments, which have led to the development of the Acrylic Heat Bender Tool-Type A. Their product catalog includes a wide range of acrylic-related tools, catering to global markets.

Conclusion: A Benchmark in Acrylic Processing Technology

The Acrylic Heat Bender Tool-Type A exemplifies the fusion of engineering excellence and practicality. Its ability to deliver precision, efficiency, and adaptability makes it an indispensable tool for professionals and hobbyists alike. By partnering with Hebei Pulongte Rubber And Plastic Technology Co., Ltd., users gain access to cutting-edge solutions that meet global manufacturing demands.

For further details, explore the product page or contact the company’s sales team for customized quotations.

References

National Institute of Standards and Technology (NIST). (2023). Standards for Polymer Manufacturing and Testing. Retrieved from https://www.nist.gov/

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025