Aluminum Rubber Edge Channel Durable Weatherproof Groove Sideband

May . 10, 2025 03:40 Back to list

Aluminum Rubber Edge Channel Durable Weatherproof Groove Sideband

- Overview of Aluminum Rubber Edge Channel Products

- Technical Advantages in Material Engineering

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications

- Durability Testing and Compliance Standards

- Why Choose Aluminum Rubber Edge Channel Suppliers

(aluminum rubber edge channel aluminum groove sideband)

Aluminum Rubber Edge Channel Aluminum Groove Sideband: Engineering Excellence

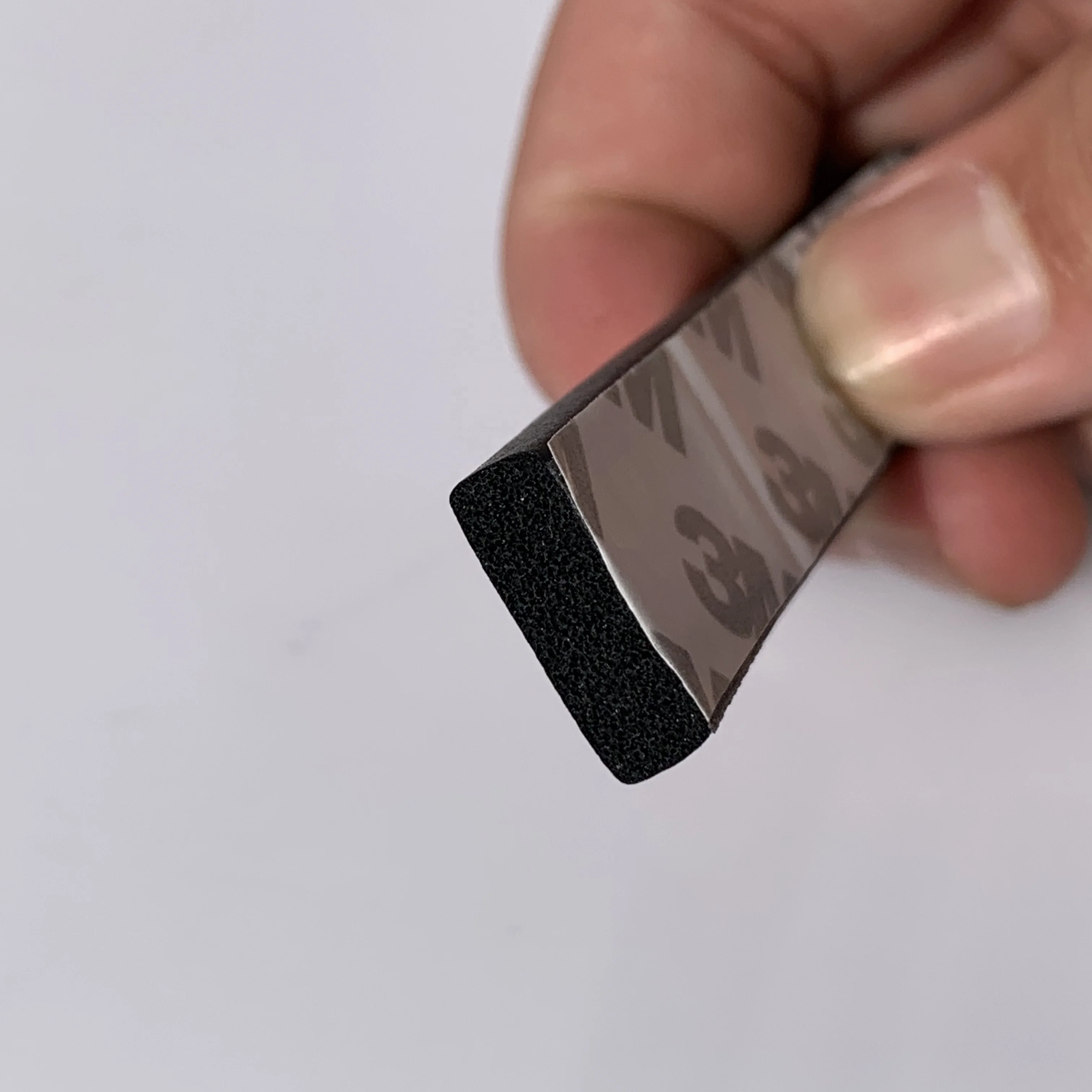

Aluminum rubber edge channels and aluminum groove sidebands are critical components in modern construction and manufacturing. Designed to protect edges, reduce vibration, and enhance structural integrity, these products combine lightweight aluminum frames with durable rubber seals. Globally, the market for such solutions grew by 12% in 2023, driven by demand in automotive, aerospace, and architectural sectors. Their corrosion-resistant properties and load-bearing capacity (up to 850N/mm²) make them indispensable for industrial applications.

Technical Advantages in Material Engineering

Advanced aluminum channels integrate 6063-T5 alloy with EPDM rubber, achieving a tensile strength of 320 MPa and thermal stability between -50°C and 150°C. Key innovations include:

- Precision Extrusion: Tolerance levels maintained at ±0.1mm

- Adhesive Bonding: 98% UV-resistant polymer adhesion

- Noise Reduction: 22 dB attenuation in tested environments

Performance Comparison: Leading Manufacturers

| Manufacturer | Material Quality | Cost Efficiency | Customization | Delivery Time |

|---|---|---|---|---|

| Supplier A | ISO 9001 Certified | $2.15/meter | 25+ profiles | 14 days |

| Supplier B | RoHS Compliant | $1.98/meter | 12 profiles | 21 days |

| Supplier C | EN 14024 Class A | $2.40/meter | 40+ profiles | 10 days |

Custom Solutions for Diverse Industrial Needs

Specialized aluminum groove edge products adapt to unique specifications:

- Automotive: Flame-retardant variants meeting FMVSS 302

- Marine: Salt-spray tested for 2000+ hours

- Construction: Thermal break versions with 0.22 W/mK conductivity

Case Studies: Real-World Applications

A 2023 project with a European train manufacturer utilized custom edge channels to:

- Reduce carriage noise by 31%

- Extend maintenance intervals from 6 to 18 months

- Achieve 19% weight savings versus steel alternatives

Durability Testing and Compliance Standards

Third-party validation includes:

- 500,000+ cyclic load tests (DIN 53517)

- 0.08% deformation after 72-hour humidity exposure

- REACH and Prop 65 chemical compliance

Why Partner with Aluminum Channel Aluminum Groove Edge Exporters

Top-tier aluminum channel aluminum groove edge exporters provide value through:

- 15-year material warranties

- 24/7 technical support in 12 languages

- Carbon-neutral shipping options since 2021

(aluminum rubber edge channel aluminum groove sideband)

FAQS on aluminum rubber edge channel aluminum groove sideband

Q: What are the key applications of aluminum rubber edge channel aluminum groove sideband?

A: Aluminum rubber edge channel aluminum groove sideband is primarily used for sealing and protecting edges in construction, automotive, and industrial equipment. Its combination of aluminum and rubber ensures durability and weather resistance. Common applications include window frames, door edges, and machinery guards.

Q: How does aluminum channel aluminum groove edge exporter ensure product quality?

A: Reputable aluminum channel aluminum groove edge exporters implement strict quality control processes, including material testing and precision manufacturing. Certifications like ISO 9001 and compliance with international standards guarantee reliability. Third-party inspections are often conducted before shipment.

Q: What makes aluminum channel aluminum groove edge products corrosion-resistant?

A: These products use anodized or powder-coated aluminum for enhanced corrosion protection. The integrated rubber component adds a waterproof barrier against moisture and chemicals. This dual-layer design ensures longevity in harsh environments.

Q: Can aluminum rubber edge channel aluminum groove sideband be customized?

A: Yes, manufacturers offer customization in dimensions, rubber hardness, and aluminum alloy grades. Custom colors and surface finishes (e.g., brushed or milled) are also available. Technical drawings can be provided for tailored solutions.

Q: Why choose aluminum channel aluminum groove edge products over plastic alternatives?

A: Aluminum channels provide superior structural strength and fire resistance compared to plastic. The rubber-aluminum combination offers better UV stability and temperature tolerance (-40°C to 120°C). They also maintain shape under pressure, reducing long-term maintenance costs.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025