Best window seal strip adhesive companies: OEM, ISO—why us?

Oct . 01, 2025 11:25 Back to list

Best window seal strip adhesive companies: OEM, ISO—why us?

Practical Guide to Choosing Window Seal Strip Adhesive Partners

If you’ve ever chased a draft around a window or garage door, you already know why the right adhesive-backed seal matters. Among window seal strip adhesive companies, the differences are surprisingly real: resin choices, adhesive chemistries, extrusion tolerances, even which standards they test to. I’ve walked a few factory floors where line speed and cooling baths decide whether a seal sits perfectly or curls up after a season. To be honest, the best vendors mix discipline with a dose of pragmatism—because doors and frames in the wild aren’t laboratory-straight.

What’s trending now

Three shifts stand out: low-VOC acrylic PSAs for indoor installs, UV-stabilized PVC and EPDM blends for longer outdoor service, and pre-primed backings that bond on powder-coated frames. Many customers say pre-taped seals cut install time by half, though, in real-world use, surface prep still decides success. And yes, price pressure is intense—but failure callbacks are costlier. That’s why serious window seal strip adhesive companies publish peel/shear data you can actually compare.

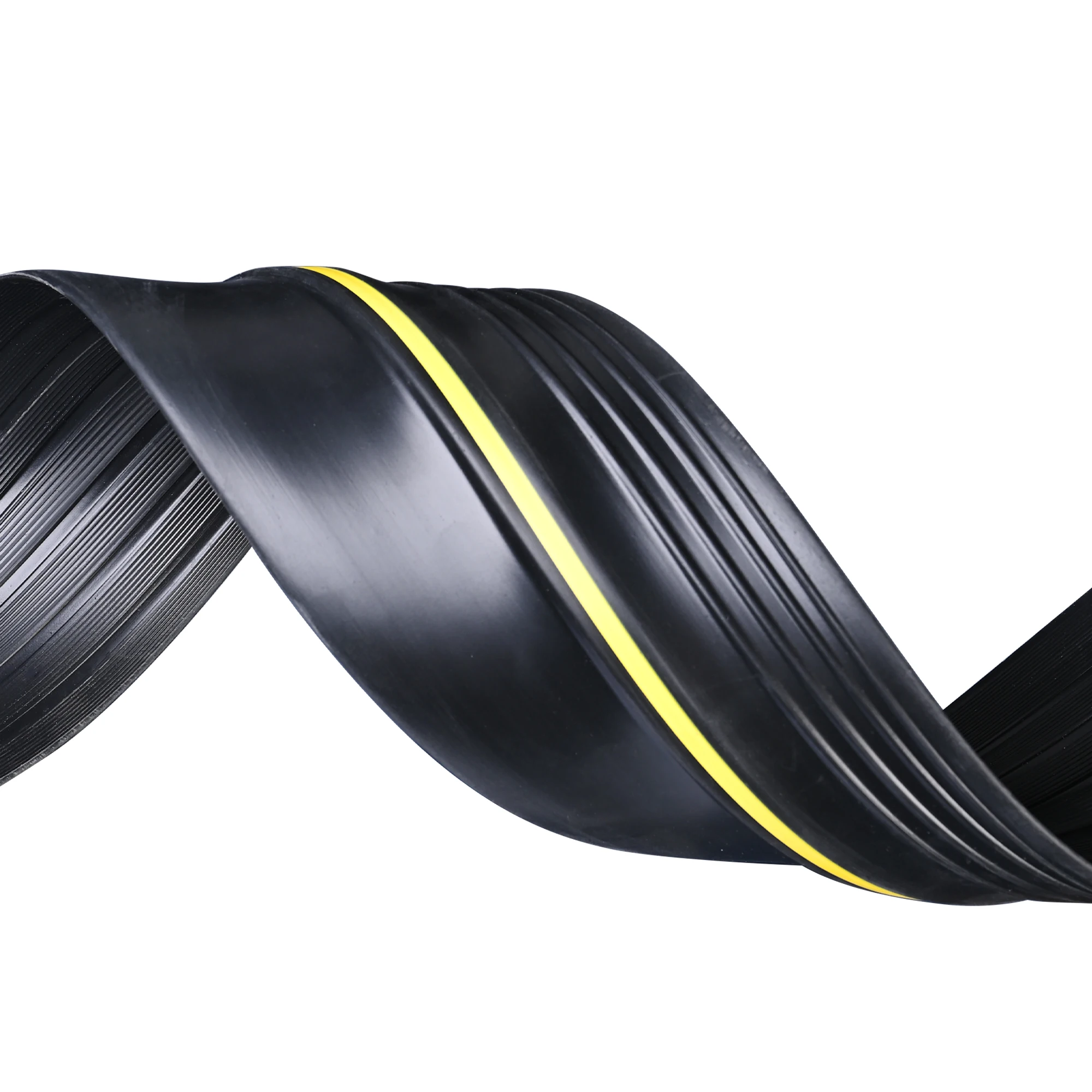

Product spotlight: Universal PVC threshold seal (garage/door)

From Xiangjiang Street South, Jinggangshan Road West, Qinghe County, Xingtai City, Hebei Province, this Universal PVC Garage Door Bottom Threshold Seal Strip aims at the pain points: stop water, dust, pests, light gaps. It’s an extruded PVC weather strip (often called “rubber seal”) that mates to the floor; doors compress onto it. Installation is typically with construction adhesive or PSA tape—your call. In fact, a site foreman told me they installed four bays before lunch, which tracks with what I’ve seen.

| Spec | Details (≈ typical; real-world use may vary) |

|---|---|

| Material | UV-stabilized PVC extrudate; black/gray options |

| Hardness | Shore A 65 ± 5 (ASTM D2240) |

| Adhesive options | Construction adhesive bead or pre-applied acrylic PSA tape (ASTM D3330 reference) |

| Temperature range | -20°C to 70°C continuous; short peaks ≈80°C |

| Compression set | ≤35% @ 25% deflection, 70°C, 22h (ASTM D395) |

| Service life | ≈5–8 years outdoors with normal UV exposure (ISO 4892-2 aging reference) |

Process flow, testing, and certifications

Materials: PVC compound with plasticizers, UV absorbers, and pigments. Methods: hot extrusion through a profile die; optional primer and PSA lamination; cut-to-length; logo/lot coding. QC: durometer (ASTM D2240), tensile (ASTM D638), compression set (ASTM D395), PSA peel (ASTM D3330), shear (ASTM D3654), and UV aging (ISO 4892-2). For doors/windows, EN 12365 and AAMA 701/702 provide performance framing. Many serious window seal strip adhesive companies will also offer RoHS/REACH material declarations and, where required, UL 94 HB flammability documentation for components.

Who’s who: vendor snapshot

| Vendor | Strengths | Watch-outs |

|---|---|---|

| Pulongte (Hebei) | Custom extrusions, floor-threshold expertise, flexible MOQs | Confirm adhesive system fit for your substrate |

| Global PSA Tape Brand | Robust acrylic PSAs, strong data packages | Higher price; lead-time peaks seasonally |

| Regional EPDM Extruder | Excellent elastic recovery; custom profiles | May need primer for powder-coated frames |

Field notes (mini case study)

A coastal distribution hub replaced worn brush seals with PVC thresholds along eight loading bays. Surface was diamond-ground concrete; they used a moisture-cure construction adhesive bead plus mechanical end stops. After 30 days, a simple smoke-pencil test showed ≈30% less infiltration at sill corners, and the night shift noted fewer insects (not scientific, but the janitor was thrilled). Adhesion remained solid after three months of salt-air exposure—helped by proper prep: degrease, dry-fit, then full-bond.

Quick checklist when vetting suppliers

- Ask for peel/shear data (ASTM D3330/D3654) on your exact substrate.

- Request UV and compression-set results, plus service-life assumptions.

- Confirm compliance docs (RoHS/REACH) and change-control process.

- Pilot a small lot in both summer and winter conditions.

Authoritative citations

- ASTM D3330: Peel Adhesion of Pressure-Sensitive Tape.

- ASTM D395: Compression Set of Rubber Materials.

- ASTM D2240: Durometer Hardness (Shore).

- ISO 4892-2: Plastics—Methods of exposure to laboratory light sources.

- EN 12365 & AAMA 701/702: Performance requirements for weatherseals and glazing gaskets.

- ASTM D3654: Holding Power of Pressure-Sensitive Tapes.

- UL 94: Tests for Flammability of Plastic Materials (HB classification).

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025