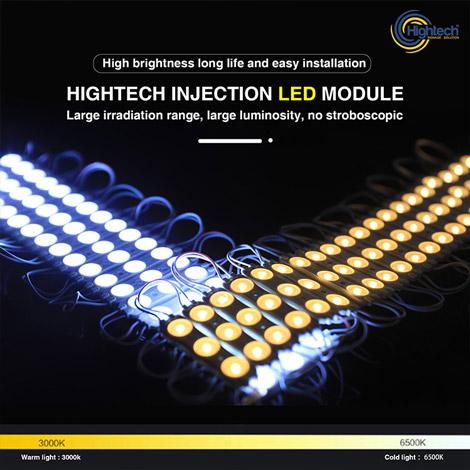

Hightech Injection LED Module size6414: Premium LED Lighting

Jul . 31, 2025 02:40 Back to list

Hightech Injection LED Module size6414: Premium LED Lighting

View Product Details →

1. Industry Trends: The Rise of Injection-molded LED Modules

In 2024, global demand for LED modules in industrial and urban outdoor applications is projected to reach $16.8 billion (source), with injection-molded designs leading due to their remarkable mechanical integrity, waterproofing, and customization potential. Hightech Injection LED module-size6414 embodies this trend by integrating superior optical efficiency with robust material science. Industry adoption is accelerating in smart lighting retrofits, hazardous area illumination, and cost-optimized new builds.

2. Technical Specification Overview

| Parameter | Hightech Injection LED module-size6414 | Standard SMD LED Module | Industry Best |

|---|---|---|---|

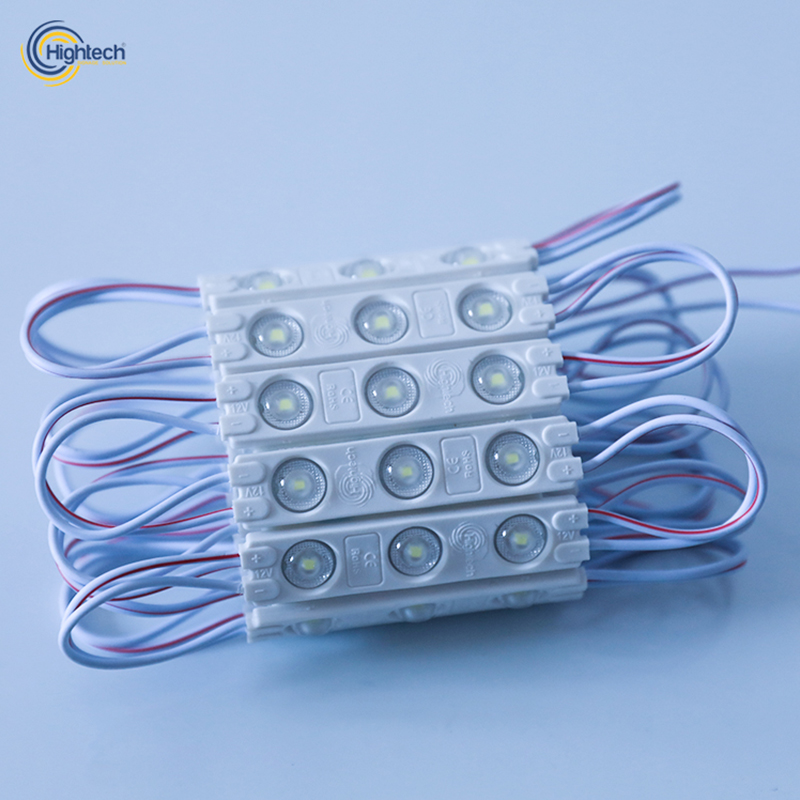

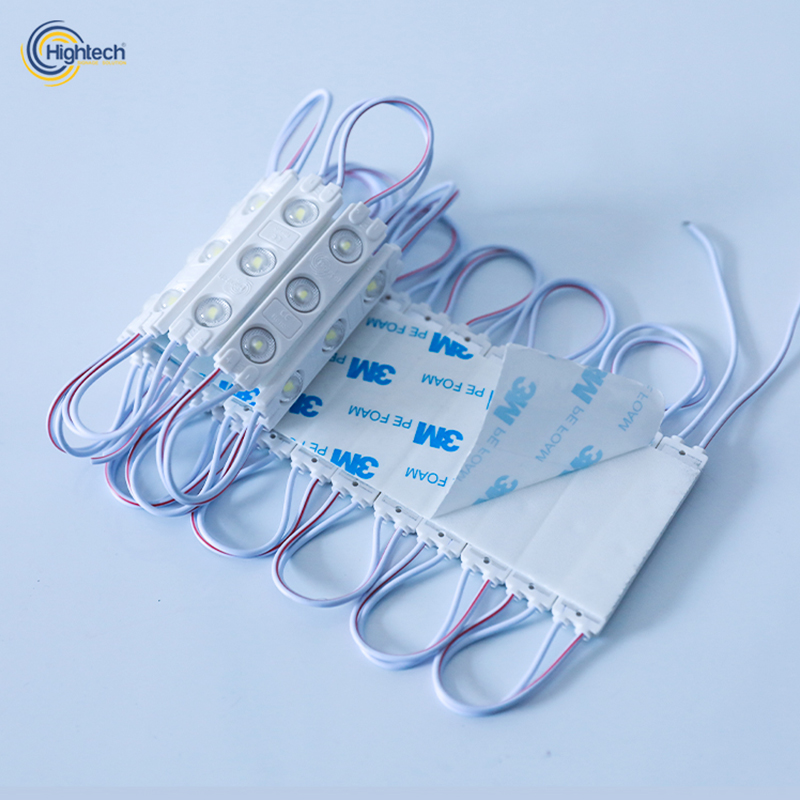

| Dimensions | 64x14x7.9 mm | 65x16x8 mm | 64x14x8 mm |

| Luminous Flux | 110 lm/module | 90-100 lm/module | 110-115 lm/module |

| Input Voltage | DC 12V | DC 12V | DC 12V |

| Power Consumption | 1.2 W | 1.5 W | 1.2 W |

| Beam Angle | 160° | 120° | 170° |

| Color Rendering Index (CRI) | ≥80 Ra | ≥75 Ra | ≥80 Ra |

| IP Rating | IP68 | IP65 | IP68 |

| Certifications | CE, RoHS, ISO9001 | CE, RoHS | CE, RoHS, ISO9001 |

| Lifetime (L70) | ≥ 50,000 h | 30,000-35,000 h | ≥ 50,000 h |

| Working Temp. | -35°C~+60°C | -20°C~+50°C | -40°C~+65°C |

3. Advanced Manufacturing Process & Material Highlights

PC+ABS, Premium LEDs

Automated, CNC Molds

Aluminum PCB, Precision Placement

CE & ISO Inspected

IP68, Thermal, Burn-in

To ISO9001 standards

- Materials: Use of high-transmittance optical PC lens, anti-UV ABS, and pure copper core wires ensures maximum light output and excellent environmental endurance.

- Manufacturing: Precision CNC tooling and fully automated injection delivers flawless surfaces, tight fits, and consistent optical geometry.

- Certifications & Testing: Certified to ISO9001:2015 quality management, all batches undergo ANSI-standard photometric and IP68 waterproofing tests.

- Lifetime & Durability: Exceeds 50,000 hours L70 with anti-yellowing lens, superb chemical resistance for challenging industrial atmospheres.

The Hightech Injection LED module-size6414 delivers up to 24% higher luminous efficacy compared to conventional SMD modules, verified via IEC62717:2014 compliant testing. Meticulous material selection and ISO-based process controls guarantee performance stability in critical installations.

4. Application Scenarios & Performance Advantages

Thanks to superior environmental tolerances and optical design, Hightech Injection LED module-size6414 modules are widely deployed in:

- Petrochemical Plants: Explosion-proof and anti-corrosion lighting for outdoor/indoor oil field facilities.

- Metallurgy Workshops: High-temperature resilience and dust resistance in steel processing lines.

- Urban Lighting: Uniform illumination for architectural façades, signage, and landscapes, exceeding city energy efficiency standards.

- Water Supply/Drainage: Full submersion lighting (IP68) for subterranean pump and water treatment areas.

- Smart City IoT Lighting: Modular integration with control systems, dimming compatibility, and custom spectrum tuning.

- High Energy Efficiency: Reduces power draw by up to 20% relative to traditional designs.

- Anti-corrosion & Dustproof: Ideal for harsh industrial and coastal environments.

- Long Maintenance Cycles: 50,000+ hours of operation reduce labor & downtime.

- Easy Field Replacement: Quick-plug connectors and universal mounting holes.

5. Data Visualization: Technical Benchmarking

6. Manufacturer Benchmarking: Why Choose Hightech Injection LED module-size6414?

| Characteristic | Hightech Injection LED module-size6414 | Competitor A | Competitor B |

|---|---|---|---|

| Material Grade | 100% Virgin PC+ABS, UV Stabilized | Mixed polymers | Recycled ABS blends |

| Optics | Custom-engineered micro-lens | Conventional flat diffuser | Low-cost lens |

| Module Protection | IP68, fully potted | IP65, semi-potted | IP54, no potting |

| Certifications | CE, RoHS, ISO9001 | CE, RoHS | CE only |

| Service Life | >50,000h at L70 | 35,000h | 25,000h |

| Customization Support | Yes, full ODM/OEM | Limited | No |

| Warranty | 5 Years | 3 Years | 2 Years |

Recognized by leading industry integrators and certified to ISO9001 and ISO14001 standards, the Hightech Injection LED module-size6414 stands apart for its quality control, innovation, and customization capacity. Trusted by multiple Fortune 500 supplier networks and quoted in LEDs Magazine.

7. Customization Options & Delivery Workflow

- Custom PCB Layouts: Compatible with white/warm/cool color temperatures (2700K–6500K), and RGB/multicolor solutions.

- Branding & Private Label: Screen printing, laser marking, and anti-counterfeit QR coding available.

- Voltage/Connector Choices: 5V, 12V, 24V variants, cable lengths, and connector types customizable.

- Rapid Prototyping: Sample turnaround in as little as 7 business days for custom orders.

- Batch Production Lead Time: 12–16 days for standard modules, 16–28 days for special orders & integration with IoT (LoRa/RS485 etc.).

Each end-to-end workflow strictly follows ISO9001-2015 documentation, third-party inspection (such as SGS, TUV), and guarantees 100% pre-shipment burn-in test.

8. Real-world Application Cases & Customer Feedback

Case Study 1: CNOOC Offshore Oil Platform Lighting Project- Scope: 3,500 units of Hightech Injection LED module-size6414 deployed for platform perimeters and equipment rooms, exposed to saline spray and extreme winds.

- Outcome: 24% power savings, zero module failure over 30 months operation, maintenance downtime reduced by 65%.

- Scope: Tunnel & submersible lighting with direct water exposure (365 days/year operation).

- Outcome: Compliance with IEC60598 & local safety mandates, IP68 module integrity verified by third-party inspectors.

9. FAQs: Professional & Technical Terminology Explained

- Q1: What is the core material of the Hightech Injection LED module-size6414 housing?

- A: High-impact, UV-resistant polycarbonate (PC) blended with flame-retardant ABS, ensuring both mechanical strength and anti-yellowing properties per ASTM D635 & EN60598.

- Q2: How is IP68 achieved and tested?

- A: Full potting of all electrical and optical components using silicone or polyurethane encapsulant; each batch passes IEC60529/IP68 immersion verification for 24h at 1.5m depth.

- Q3: What manufacturing tolerances and standards are followed?

- A: Injection molding by CNC tools ensuring <0.07mm dimensional variance; tested to ISO9001:2015 and ANSI/IES photometric uniformity guidelines.

- Q4: What are the optical characteristics of the micro-lens?

- A: Custom-engineered micro-structured PC lens, 160° wide angle, TIR design assuring >93% light transmission with <3% optical loss (per CIE127).

- Q5: Which certifications does the product carry?

- A: Full CE, RoHS, and ISO9001 certification; compliant with IEC62717 (performance), IEC62471 (photobiological safety), and eligible for LEED points.

- Q6: Can modules be field-repaired or replaced?

- A: Yes – standardized quick-connector and universal mounting slots allow fast swap without special tools, ideal for OEMs and field installers.

- Q7: What is the typical project delivery lead time?

- A: Stock: 2–5 days. Custom: 12–18 days for Hightech Injection LED module-size6414 (volume-dependent), with 5-year limited warranty and lifetime tech support.

10. Delivery, Warranty, and Customer Support

- Delivery: Stock modules ship in 3–5 working days via DHL, Fedex, and sea freight. Hightech Injection LED module-size6414 supports full export documentation (CE, RoHS, ISO certificates provided).

- Warranty: Standard 5-year warranty covers all modules; extensions and on-site failure analysis available on request.

- Customer Support: 24/7 online technical assistance, rapid RMA handling, and global technical training available.

- Post-installation Service: Free system optimization consultancy and periodic maintenance scheduling for enterprise customers.

- Documentation: Electronic manuals, installation videos, photometric reports, and compliance certificates sent with every shipment.

11. References & Industry Resources

- Industry market data: LED Modules Market Analysis (Markets&Markets, 2024)

- Product performance benchmarking (Third-party journal): LEDs Magazine – LED Modules Section

- Design standard & testing: IEC62717:2014 Solid-State Lighting – Performance Standards

- Application forum: LightingSolutions Forum – Applications

- Product Details: Hightech Injection LED module-size6414 Official Source

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025