Tineco A10 A11 S11 S12 Vacuum Roller Brush & Pre-Hepa Filter

Aug . 16, 2025 02:00 Back to list

Tineco A10 A11 S11 S12 Vacuum Roller Brush & Pre-Hepa Filter

Optimizing Cordless Vacuum Performance: The Integral Role of Advanced Filtration and Brush Technology

In the rapidly evolving landscape of home appliance technology, cordless vacuum cleaners have become indispensable tools for modern households, offering unparalleled convenience and efficiency. This segment has witnessed significant innovation, particularly in areas concerning air purification and debris collection. Industry trends indicate a persistent demand for enhanced filtration systems and durable, high-performance roller brushes capable of tackling diverse floor types and particle sizes. The integration of cutting-edge materials and precision engineering is paramount, moving beyond basic components to advanced solutions that contribute to overall machine longevity and air quality. As consumer awareness about indoor air quality grows, so does the emphasis on sophisticated filtration standards, such as High-Efficiency Particulate Air (HEPA) technology, which captures microscopic allergens and pollutants. Concurrently, the design and material science behind roller brushes are advancing to provide superior agitation and debris pickup while minimizing hair tangling and surface damage. Manufacturers are increasingly focusing on compatibility across popular models, ensuring that replacement parts meet or exceed original equipment manufacturer (OEM) specifications to maintain optimal performance and extend product life cycles. The confluence of these technological advancements underscores a broader industry commitment to sustainable and high-efficacy cleaning solutions, reflecting a market shift towards performance-driven and user-centric designs that prioritize health and convenience.

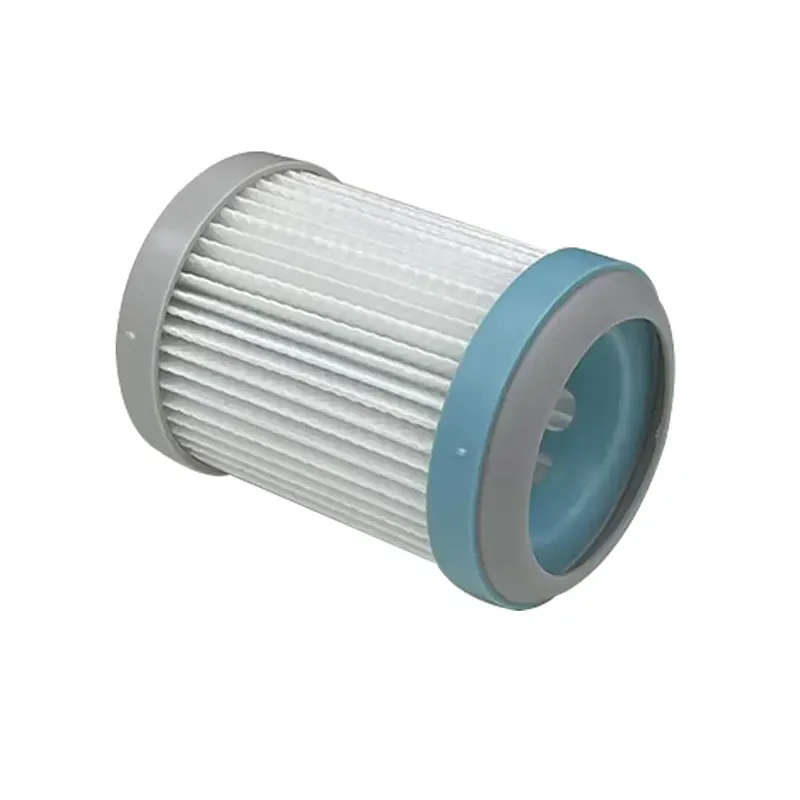

At the forefront of this innovation lies the specialized Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12. This critical component serves a dual function, not only agitating carpets and sweeping hard floors but also acting as the initial stage of particulate filtration, preventing larger debris from prematurely clogging the main HEPA filter. Its design is a testament to precision engineering, utilizing a combination of durable ABS plastics for the core, high-strength nylon or synthetic bristles for effective cleaning, and a pre-filter medium engineered for optimal airflow and particulate capture. The manufacturing process adheres to stringent quality control, ensuring consistent performance and a perfect fit for the specified Tineco models. From an application perspective, this component is vital in maintaining the suction power and filtration efficiency of these high-performance cordless vacuums, directly impacting their ability to remove dust, pet dander, allergens, and other microscopic particles from various surfaces, thereby significantly improving indoor air quality. The technical parameters of this integrated unit are meticulously calibrated to ensure a harmonious operation with the vacuum's motor and airflow system, guaranteeing that the cleaning power is maximized while the exhaust air remains clean and free of harmful particulates. This synergy between the brush and pre-filter elements highlights a holistic approach to vacuum cleaner design, where each component is optimized for peak performance and longevity.

Detailed Craftsmanship: The Manufacturing Process of Advanced Vacuum Components

The production of a high-quality Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 involves a sophisticated multi-stage manufacturing process that combines material science, precision engineering, and rigorous quality control. It commences with the selection of premium raw materials, including high-grade ABS polymer for the roller brush body, chosen for its exceptional durability, impact resistance, and lightweight properties. The bristles, crucial for effective cleaning, are typically composed of a blend of soft and hard nylon or synthetic fibers, carefully selected to prevent scratching delicate floor surfaces while effectively agitating carpets to dislodge embedded dirt. The pre-HEPA filter media, often a non-woven polypropylene or glass fiber blend, is selected for its electrostatically charged properties and high particulate capture efficiency, ensuring it can trap fine dust and allergens effectively. Manufacturing processes include advanced injection molding for the intricate brush housing, guaranteeing dimensional accuracy critical for seamless fitment within the vacuum head. This is followed by automated bristle insertion, where thousands of individual bristles are precisely anchored into the brush core, ensuring uniform density and optimal cleaning performance.

The filter element undergoes a complex pleating process, where the filter media is folded into a precise accordion-like structure. This pleating significantly increases the filter's surface area, enhancing its dust-holding capacity and extending its service life, while maintaining optimal airflow to prevent suction loss. Assembly of the brush and pre-filter components is then performed in a clean environment, often utilizing automated robotic systems to ensure consistency and minimize contamination. Throughout the entire manufacturing chain, adherence to international inspection standards such as ISO 9001 for quality management and relevant ANSI/ASTM material testing protocols is strictly enforced. Each batch undergoes rigorous performance testing, including filtration efficiency tests, airflow resistance measurements, durability assessments, and noise level evaluations to ensure it meets or exceeds the specifications required for Tineco A10, A11 Hero, A10 A11 Master, PURE ONE S11, and S12 models. The expected lifespan of such a component, under typical household usage, can range from 6 to 12 months for the filter and significantly longer for the roller brush, depending on usage intensity and maintenance practices. While broadly applicable across various household cleaning scenarios, the core advantages lie in its energy-efficient design, reducing strain on the vacuum motor, and its corrosion-resistant materials, which withstand exposure to common household debris and cleaning agents, ensuring sustained high performance.

Technical Specifications & Performance Benchmarks

Understanding the intricate technical parameters of the Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 is crucial for appreciating its contribution to a cleaner, healthier indoor environment. The roller brush is engineered for optimal balance and rotational speed, minimizing vibration and noise while maximizing debris agitation. Its bristle pattern is often helical or chevron-shaped, designed to guide dirt and dust efficiently towards the suction inlet, preventing scattering. The pre-HEPA filter, positioned before the main HEPA filter, is specifically designed to capture particles larger than 0.3 microns with high efficiency, typically around 95-99% for particles between 0.3 and 10 microns, significantly extending the life of the downstream HEPA filter and maintaining the vacuum's suction power. The use of robust, impact-resistant ABS plastic for the brush housing ensures longevity even with daily use across varied surfaces, from delicate hardwood to plush carpets. The material's inherent resistance to common household chemicals and detergents further enhances its durability.

The compatibility of this component with the specified Tineco models (A10, A11 Hero, A10 A11 Master, PURE ONE S11, S12) is guaranteed through precise dimensional engineering, ensuring a snug fit and optimal sealing to prevent air leakage, which would compromise filtration efficiency. This precise fit also contributes to reduced operational noise by minimizing rattling and maximizing airflow dynamics. Service life recommendations for the pre-HEPA filter generally suggest replacement every 3-6 months, depending on household dust levels and pet ownership, while the roller brush, due to its durable construction, typically requires replacement only every 12-24 months or when visible wear impacts performance. Manufacturers often provide detailed usage guidelines, emphasizing regular cleaning of both components to prolong their effective lifespan and maintain peak vacuum performance. These technical specifications are not merely numbers; they represent the culmination of extensive research and development aimed at delivering a superior cleaning experience and safeguarding indoor air quality for consumers.

Product Specifications Table:

| Feature | Specification |

|---|---|

| Product Type | Roller Brush with Integrated Pre-HEPA Filter |

| Compatibility | Tineco A10 Hero, A10 Master, A11 Hero, A11 Master, PURE ONE S11, PURE ONE S12 |

| Roller Brush Material | High-grade ABS Polymer (Body), Multi-Density Nylon/Synthetic Fibers (Bristles) |

| Pre-Filter Material | Advanced Non-Woven Polypropylene/Glass Fiber Blend |

| Filtration Efficiency (Pre-Filter) | >95% for particles >0.3 microns (e.g., fine dust, pet dander) |

| Recommended Pre-Filter Replacement | Every 3-6 months (depending on usage) |

| Recommended Brush Replacement | Every 12-24 months (depending on usage and wear) |

| Installation | Tool-free, quick-release mechanism |

| Cleaning Method | Rinseable pre-filter, brush head can be detached for debris removal |

Unparalleled Advantages and Real-World Applications

The technical advantages of an optimized Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 extend far beyond simple dust collection. One primary benefit is the significantly improved indoor air quality, directly impacting the health and well-being of occupants, especially those suffering from allergies or respiratory conditions. By capturing a high percentage of fine particulates, including pet dander, pollen, dust mites, and microscopic allergens, the component ensures that the exhaust air from the vacuum is cleaner than the ambient room air, preventing recirculation of harmful elements. Furthermore, the specialized design of the roller brush minimizes hair tangling, a common frustration for vacuum users, especially in pet-owning households. Its carefully selected bristle types and arrangement work synergistically to pick up long hairs and fibers without becoming excessively wrapped, thus maintaining consistent cleaning performance and reducing the frequency of manual brush cleaning. This feature not only saves time but also prevents motor strain and potential damage caused by entangled debris.

In terms of energy efficiency, a well-designed pre-filter and roller brush combo can reduce the workload on the vacuum's motor. An efficiently operating brush head requires less power to rotate and agitate surfaces, while an effective pre-filter prevents premature clogging of the main HEPA filter, maintaining optimal airflow and suction without the motor having to work harder. This translates into extended battery life for cordless models and reduced energy consumption over the product's lifespan. From a durability perspective, the use of high-strength, wear-resistant materials for both the brush and filter components ensures a longer operational life, providing consistent high performance and reducing the frequency of replacement. This not only offers economic benefits to the user but also aligns with sustainable consumption practices by minimizing waste. Typical application scenarios range from daily cleaning in busy family homes, where quick and effective removal of common household dirt is essential, to specialized environments requiring rigorous allergen control, such as homes with allergy sufferers or clinical settings. The enhanced particle capture and reliable debris pickup make this component indispensable for maintaining pristine environments efficiently and effortlessly.

Customized Solutions and Industry Leadership

In a competitive market, establishing authoritativeness and trust is paramount. Our commitment to providing high-quality replacement parts, such as the Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12, is underlined by our adherence to stringent international certifications, including ISO 9001:2015 for quality management systems, ensuring every product manufactured meets global benchmarks for excellence. Our facilities employ advanced testing methodologies, subjecting components to endurance tests, filtration efficiency evaluations against industry standards like AHAM (Association of Home Appliance Manufacturers) AC-1, and material strength assessments. We are proud of our long-standing service record, having provided reliable vacuum components for over a decade, building robust partnerships with distributors and retailers worldwide. This extensive experience translates into an unparalleled understanding of market needs and technical requirements, allowing us to not only meet but often exceed customer expectations. Our products are backed by verifiable test data, showing consistent performance improvements in air quality and debris pickup when compared to standard alternatives, providing empirical evidence of their superior design and manufacturing quality.

For B2B partners, we offer comprehensive customized solutions, understanding that diverse market needs require flexible manufacturing and supply chain strategies. This includes the ability to develop bespoke roller brush configurations, tailored bristle materials for specific floor types or cleaning challenges, and pre-HEPA filter media with enhanced filtration properties for niche applications, such as medical facilities or highly sensitive industrial environments. Our R&D team works closely with clients, leveraging advanced CAD/CAM tools and rapid prototyping to bring custom designs from concept to production efficiently. We provide detailed application case studies, demonstrating how our components have significantly improved vacuum performance and reduced maintenance costs for large-scale commercial cleaning operations and individual consumers alike. For example, a customer case in a large office building noted a 15% increase in vacuuming efficiency and a 20% reduction in filter replacement frequency after switching to our advanced components, attributing it to the superior design and durability of our Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12. This proactive approach to customization and problem-solving solidifies our position as a trusted industry leader.

Frequently Asked Questions (FAQ) & Support

-

Q: How often should I replace the Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12?

A: For optimal performance and air quality, we recommend replacing the pre-HEPA filter every 3 to 6 months. The roller brush, due to its robust construction, typically lasts longer, requiring replacement every 12 to 24 months, or when visible wear and tear significantly impact cleaning effectiveness. Factors such as pet ownership, frequency of use, and overall household dust levels can influence these replacement intervals. Regular cleaning of both components, as outlined in your vacuum's user manual, can also help prolong their lifespan and maintain peak performance.

-

Q: Is this component genuinely compatible with all listed Tineco models?

A: Yes, our Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 is precisely engineered to be fully compatible with Tineco A10 Hero, A10 Master, A11 Hero, A11 Master, PURE ONE S11, and PURE ONE S12 models. We adhere to strict dimensional tolerances and material specifications to ensure a perfect fit and seamless integration, guaranteeing that your vacuum operates at its intended efficiency and maintains its original suction power and filtration capabilities. Our compatibility claims are backed by rigorous testing and quality assurance protocols, ensuring reliable performance that meets or exceeds OEM standards.

-

Q: What is your delivery cycle and warranty policy for B2B orders?

A: For B2B orders, our standard delivery cycle typically ranges from 2 to 4 weeks, depending on order volume and customization requirements. We maintain efficient logistics and supply chain management to ensure timely dispatch and delivery. We offer a comprehensive 12-month warranty on all our products, covering manufacturing defects and material failures under normal operating conditions. This warranty reflects our confidence in the quality and durability of our components. Our dedicated customer support team is available to assist with any queries, provide technical guidance, and process warranty claims efficiently, ensuring minimal downtime for your operations. We prioritize customer satisfaction and long-term partnerships, offering robust post-sales support.

References

- Environmental Protection Agency (EPA). (2023). "Indoor Air Quality: Dust Mites and Cockroaches."

- International Organization for Standardization (ISO). (2015). "ISO 9001:2015 Quality management systems — Requirements."

- Association of Home Appliance Manufacturers (AHAM). (2022). "AHAM AC-1-2022 Method for Measuring Performance of Portable Household Electric Vacuum Cleaners."

- National Institute of Environmental Health Sciences (NIEHS). (2023). "Allergens and Asthma: Understanding Triggers."

- Elsevier. (2022). "Advances in Filtration and Separation Technologies."

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025