Window Seal Strip Adhesive Companies: OEM, ISO, Fast Quotes?

Oct . 05, 2025 23:20 Back to list

Window Seal Strip Adhesive Companies: OEM, ISO, Fast Quotes?

Inside the world of window seal strip adhesives (and why furniture edging tech matters)

If you’ve spent time on factory floors like I have, you realize the same engineering DNA shows up in unexpected places. A good example: window seal strip adhesive companies share process know‑how with the folks extruding PVC edging for sofas and cabinetry—surface energy, stable bonding, UV resistance. Different end markets, same precision.

Industry snapshot: trends that stick

Demand is tilting toward low‑odor, low‑VOC acrylic PSAs, better high‑temp stability (EVs and dark frames get hot), and faster install speeds. To be honest, installers keep asking for forgiving repositionability but still want ≥6 N/25 mm peel on aluminum—quite a balancing act. Many customers say hybrid acrylics with primed surfaces give the best real‑world durability.

Featured product (tech that crosses over)

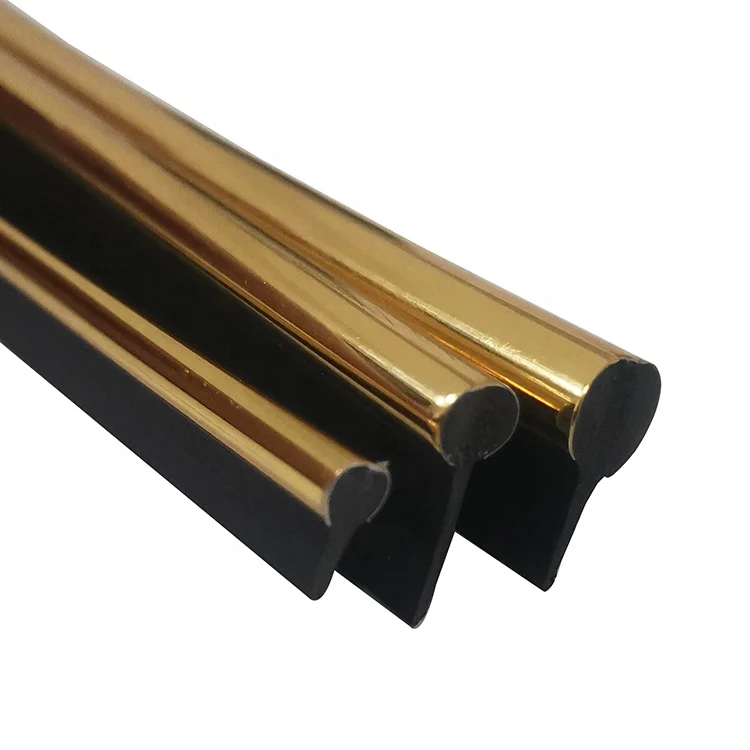

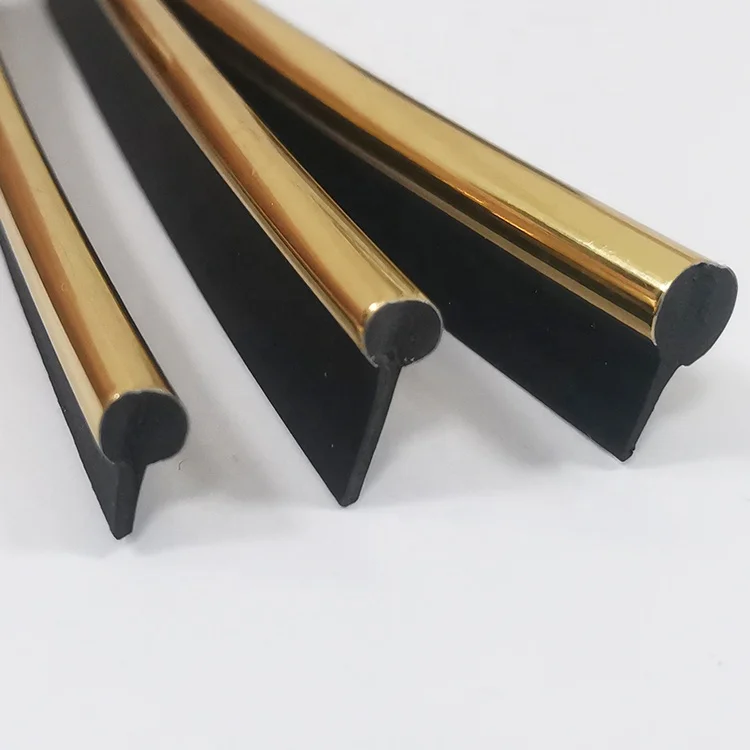

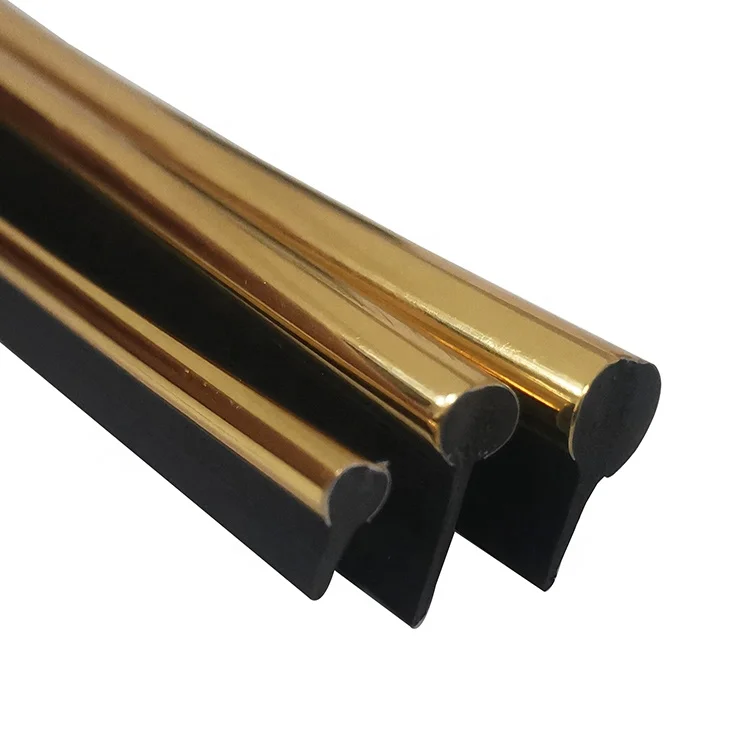

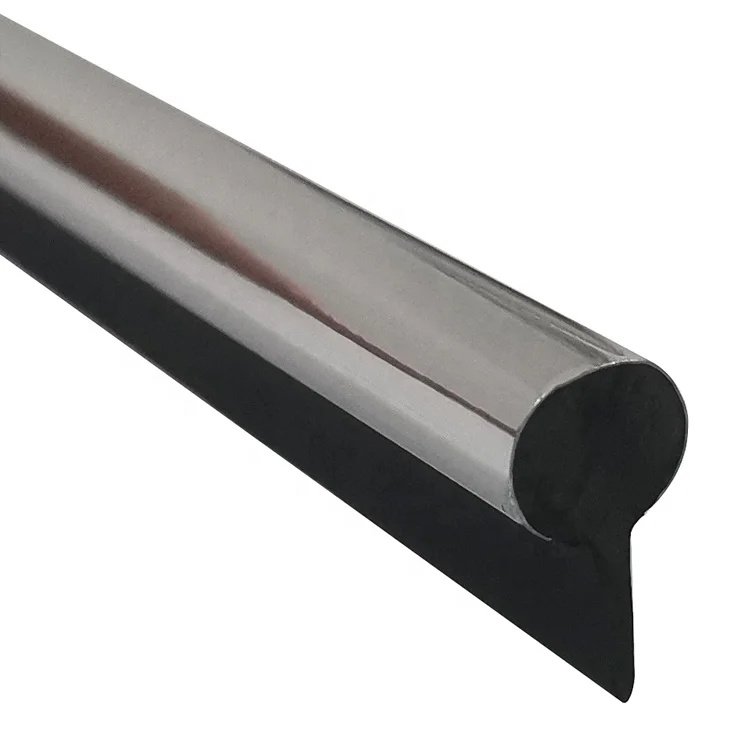

From Hebei Province—Xingtai City’s Qinghe County, to be precise—comes a flexible PVC edging that borrows the same lamination and adhesion playbook used by window seal strip adhesive companies: Customized Sizes Colorful Flexible Sofa and Furniture Chrome Gold PVC Plastic Edging Strip.

| Material | Flexible PVC core, chrome/gold decorative film |

| Size Range | Width ≈ 5–50 mm; thickness ≈ 0.6–2.0 mm (custom) |

| Color/Finish | Chrome gold plus assorted colors; gloss or matte |

| Adhesive Option | Acrylic PSA or hot‑melt PSA backing for quick install |

| Working Temp | ≈ −20 °C to 80 °C (real‑world use may vary) |

| Standards/Tests | Peel (ASTM D3330), Shore A (ISO 868), UV (ISO 4892‑2), RoHS/REACH |

Process flow (short version)

Resin compounding → precision extrusion → decorative film co‑lamination → corona treatment → optional PSA lamination + liner → slitting → 24–48 h aging → QC. Tests typically include peel (ASTM D3330), tensile (ISO 37), hardness (ISO 868), and accelerated weathering (ISO 4892‑2). Expected service life: indoors 8–10 years; exterior trims around 3–5 years depending on UV load. Honestly, climate beats specs every time.

Where it’s used

- Windows and doors: glazing beads, trim, and cover strips paired with EPDM/TPE seals.

- Furniture and sofas: edge protection with fast PSA installation—no solvent mess.

- Appliances and RV interiors: lightweight decorative edging with stable adhesion.

Vendor comparison (quick take)

| Vendor | Core Strength | Adhesive System | Lead Time | Certs |

|---|---|---|---|---|

| Pulongte (Hebei) | Custom extrusion, decorative films | Acrylic/HMPSA, primer-treated | ≈ 10–20 days | ISO 9001, RoHS/REACH |

| Vendor B (Guangdong) | High‑volume standard profiles | Acrylic PSA | ≈ 7–14 days | ISO 9001 |

| Vendor C (Zhejiang) | Automotive trim focus | Acrylic + foam tape | ≈ 15–25 days | IATF 16949 |

Case study: window retrofit, coastal city

A mid‑rise retrofit team paired acrylic‑backed TPE weatherstrips with decorative PVC trims from a supplier like window seal strip adhesive companies often collaborate with. Results after 6 months: air leakage down ≈35%, water ingress callbacks down ≈40%, install time per unit shaved by ~18%. The installer told me, “Primered PSA just bit better on powder‑coat frames—less fuss.”

Specs that usually matter

- Peel adhesion (ASTM D3330): target 6–15 N/25 mm on aluminum, around 72 h dwell.

- Shear (ASTM D3654): ≥ 20 N/625 mm² for vertical creep resistance.

- Weathering: ISO 4892‑2 QUV B exposure to validate UV colorhold and tack.

- Compliance: RoHS and REACH; for fenestration, check AAMA 701/702 and EN 12365.

Final note: customization is the quiet superpower—width, color, PSA type, liner format, even pre‑notched corners. That’s where manufacturers rooted in both furniture edging and seals tend to shine.

Authoritative references

- ASTM D3330: Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape – https://www.astm.org/d3330

- ISO 4892‑2: Plastics — Methods of exposure to laboratory light sources — Xenon-arc – https://www.iso.org/standard/64095.html

- AAMA 701/702: Voluntary Specification for Pile Weatherstripping and Weatherseals – https://aamanet.org

- EN 12365: Building hardware — Gaskets and weatherstripping – https://standards.iteh.ai/catalog/standards/cen/5f8a2d8e-...

- EU RoHS Directive 2011/65/EU; ECHA REACH – https://echa.europa.eu

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025