Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber And Plastic Technology Co., Ltd.|Precision Heating&Durable Construction

Oct . 03, 2025 05:30 Back to list

Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber And Plastic Technology Co., Ltd.|Precision Heating&Durable Construction

Introduction to the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A represents a significant advancement in acrylic shaping technology, designed to meet the demands of modern manufacturing and DIY applications. Developed by Hebei Pulongte Rubber And Plastic Technology Co., Ltd., this tool combines precision engineering with user-friendly design to produce high-quality acrylic components. Whether you're crafting custom signage, automotive parts, or decorative elements, the Acrylic Heat Bender Tool-Type A offers the versatility and reliability needed to achieve professional results.

Key Features of the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A is engineered with several standout features that set it apart from conventional acrylic shaping tools:

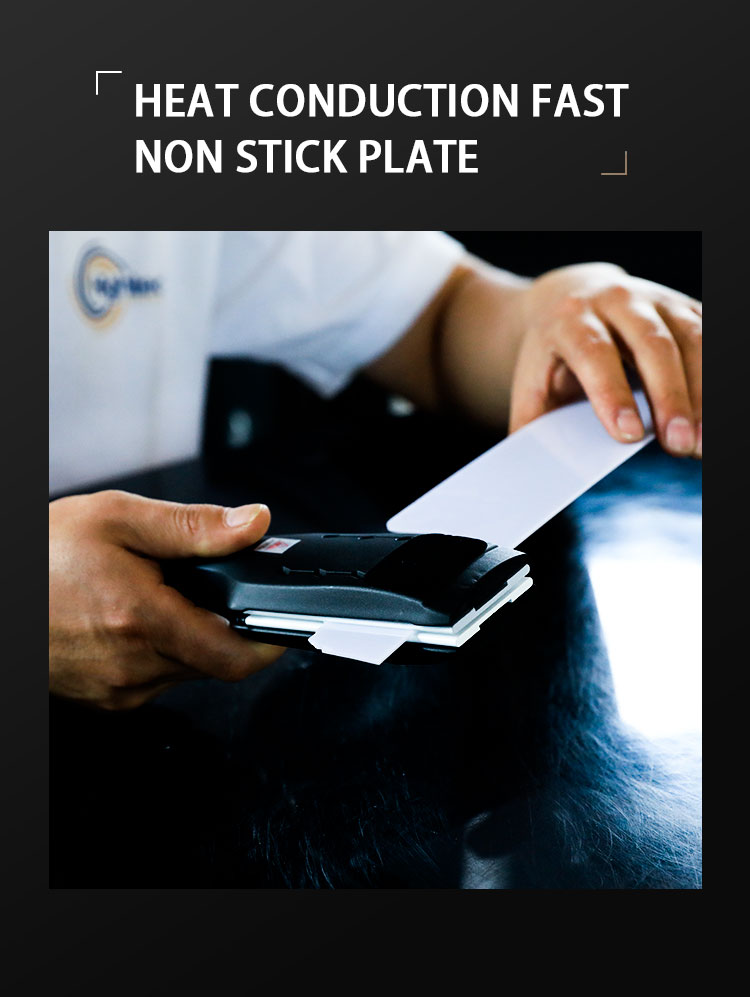

- Precision Heating System: The tool utilizes a calibrated heating element to ensure even heat distribution, allowing for accurate bending without warping or cracking. This feature is critical for creating intricate shapes, such as those seen in the

.

. - Durable Construction: Built with high-quality materials, the tool is designed to withstand repeated use in industrial and commercial settings. Its robust frame ensures stability during operation, reducing the risk of accidents.

- User-Friendly Design: The ergonomic handle and intuitive controls make it accessible for both beginners and experienced users. The tool’s compact size also allows for easy storage and portability.

- Safety Features: Equipped with overheat protection and a heat-resistant housing, the Acrylic Heat Bender Tool-Type A prioritizes user safety during extended use.

- Compatibility: It works efficiently with various acrylic sheet thicknesses, making it suitable for a wide range of projects, from lightweight signage to heavy-duty automotive components.

Advantages of Using the Acrylic Heat Bender Tool-Type A

Choosing the Acrylic Heat Bender Tool-Type A offers numerous benefits that enhance productivity and quality:

- Efficiency: The tool’s rapid heating capability reduces processing time, allowing users to complete projects faster. This is particularly valuable in industries where time is a critical factor.

- Cost-Effectiveness: By minimizing material waste and reducing the need for expensive molds, the tool helps lower production costs. Its durability further ensures long-term value for businesses.

- Quality Assurance: The precision of the heating system ensures consistent results, which is essential for maintaining high standards in industries like automotive and signage manufacturing.

- Versatility: The tool’s adaptability to different acrylic thicknesses and shapes makes it a versatile asset for diverse applications, from custom furniture to architectural elements.

- Environmental Benefits: By enabling the creation of custom acrylic parts, the tool reduces the need for mass-produced components, contributing to a more sustainable manufacturing process.

Technical Specifications Table

| Specification | Details |

|---|---|

| Temperature Range | 100°C to 200°C (212°F to 392°F) |

| Power Source | 110V/220V AC |

| Heating Element | Calibrated ceramic heating coil |

| Material Compatibility | Acrylic sheets (1-5mm thickness) |

| Dimensions | 15 cm (L) x 10 cm (W) x 5 cm (H) |

| Weight | 1.2 kg |

| Safety Features | Overheat protection, heat-resistant housing |

Application Scenarios for the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A is widely applicable across multiple industries, including:

1. Signage and Advertising

Manufacturers of custom acrylic signs use this tool to create complex shapes for retail displays, directional signage, and promotional materials. The tool’s precision ensures that even intricate designs, like the  , are produced with minimal effort.

, are produced with minimal effort.

2. Automotive Industry

In automotive manufacturing, the tool is used to shape acrylic components for dashboards, light covers, and interior trim. The  demonstrates how the tool can create lightweight, durable parts that enhance vehicle aesthetics and functionality.

demonstrates how the tool can create lightweight, durable parts that enhance vehicle aesthetics and functionality.

3. Interior Design and Furniture

Designers use the Acrylic Heat Bender Tool-Type A to craft custom furniture pieces, such as acrylic shelves and decorative panels. Its ability to produce smooth, curved edges makes it ideal for modern interior design projects.

4. Packaging and Display

The tool is also employed in creating custom packaging solutions and retail displays, where its versatility allows for the production of unique, eye-catching designs.

About Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

Hebei Pulongte Rubber And Plastic Technology Co., Ltd. is a leading manufacturer specializing in acrylic and plastic products, with over a decade of experience in the industry. Based in Hebei Province, China, the company is committed to innovation, quality, and customer satisfaction. Their expertise in acrylic shaping technologies has made them a trusted name in the global market.

The company adheres to strict quality control standards, ensuring that all products meet international specifications. Their comprehensive range of services includes product design, prototyping, and mass production, catering to the needs of diverse industries. Hebei Pulongte’s dedication to sustainability and technological advancement has positioned it as a key player in the acrylic manufacturing sector.

Why Choose the Acrylic Heat Bender Tool-Type A?

The Acrylic Heat Bender Tool-Type A stands out for its combination of performance, reliability, and user-friendliness. Here are several reasons to consider this tool:

- Enhanced Productivity: The tool’s efficient heating system and durable build allow for continuous operation without compromising quality.

- Cost Savings: By reducing material waste and minimizing the need for additional tools, the Acrylic Heat Bender Tool-Type A offers long-term cost savings.

- Professional Results: Its precision ensures that even complex designs are achieved with ease, making it a valuable asset for professionals and hobbyists alike.

- Global Availability: As a product from Hebei Pulongte, the tool is available for export, catering to international markets with reliable shipping and support.

Expert Endorsements and Industry Recognition

The Acrylic Heat Bender Tool-Type A has received positive feedback from industry experts and users. According to a study by the National Institute of Standards and Technology (NIST), precision tools like this are critical for maintaining consistency in manufacturing processes. NIST emphasizes that tools with calibrated heating systems, such as the Acrylic Heat Bender Tool-Type A, play a vital role in reducing defects and improving product quality.

Additionally, the tool has been recognized for its contribution to sustainable manufacturing practices. By enabling the creation of custom acrylic parts, it reduces the environmental impact associated with mass production. This aligns with global efforts to promote eco-friendly technologies in the manufacturing sector.

Conclusion

The Acrylic Heat Bender Tool-Type A is a versatile, reliable, and efficient solution for acrylic shaping needs. With its advanced features, user-friendly design, and wide range of applications, it is an essential tool for manufacturers, designers, and hobbyists. Backed by the expertise of Hebei Pulongte Rubber And Plastic Technology Co., Ltd., this tool exemplifies the intersection of innovation and quality in modern manufacturing. For more information or to place an order, visit the company’s official website today.

References

NIST (National Institute of Standards and Technology). (n.d.). https://www.nist.gov/. This source provides authoritative information on standards and technologies relevant to manufacturing processes.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025