Hightech Injection LED module-size6414 | High Bright, IP67

Oct . 19, 2025 12:05 Back to list

Hightech Injection LED module-size6414 | High Bright, IP67

Hands-on with the Hightech Injection LED module-size6414

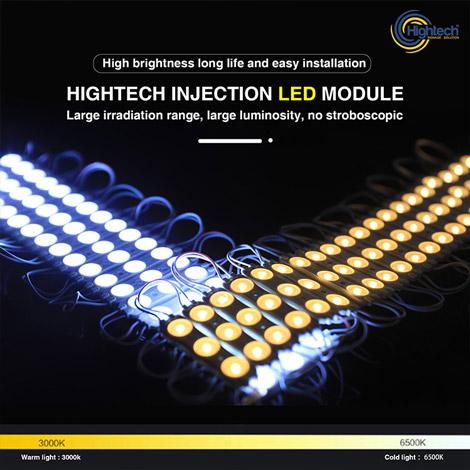

If you’ve ever wrestled with uneven signage lighting or temperamental lightboxes, you know that the humble LED module can make or break a project. The Hightech Injection LED module-size6414 is one of those small, well-engineered units that’s been popping up in spec sheets—DC12V, 1.5W, SMD2835, 160° lens, outdoor-friendly. On paper it’s familiar; in the field, it’s surprisingly forgiving and bright for its size. Industry trend-wise, we’re seeing a shift toward wide-beam, low-watt modules to reduce hotspots and simplify installation. This one leans right into that.

Key specs at a glance

| LED package | SMD 2835 (single chip) |

| Power / Voltage | 1.5 W, DC 12 V |

| Optics / Beam | Integrated injection lens, 160° wide beam |

| Luminous output | ≈ 130–150 lm per module (real-world use may vary) |

| CCT / CRI | Cool white (≈6000–7000 K), CRI ≈80 |

| Ingress protection | Waterproof design, commonly IP65–IP67 depending on configuration |

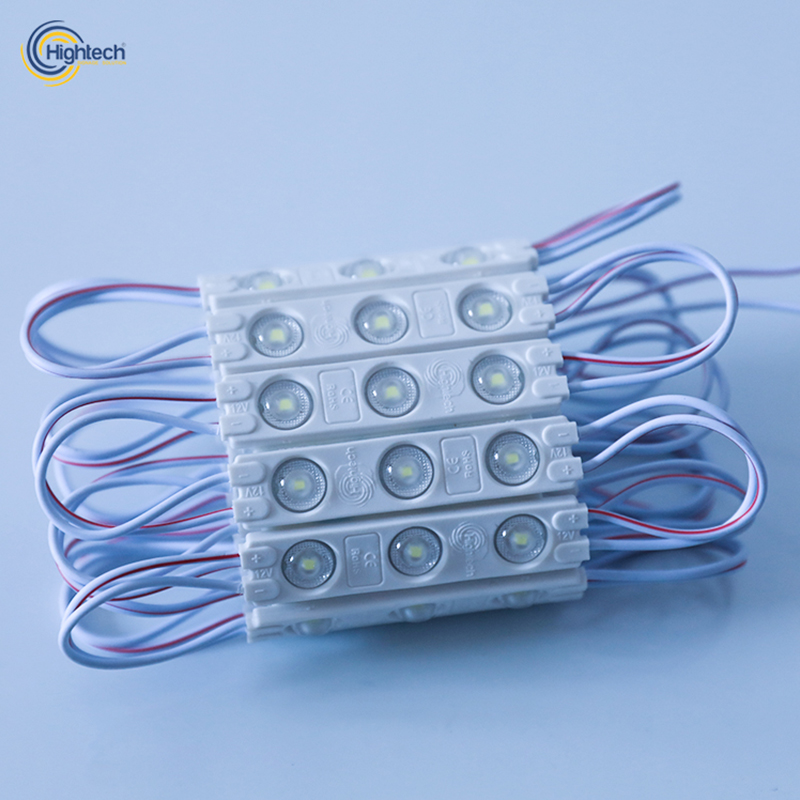

| Footprint | Compact, around “64×14 mm” class (hence size6414) |

Materials, build, and test flow

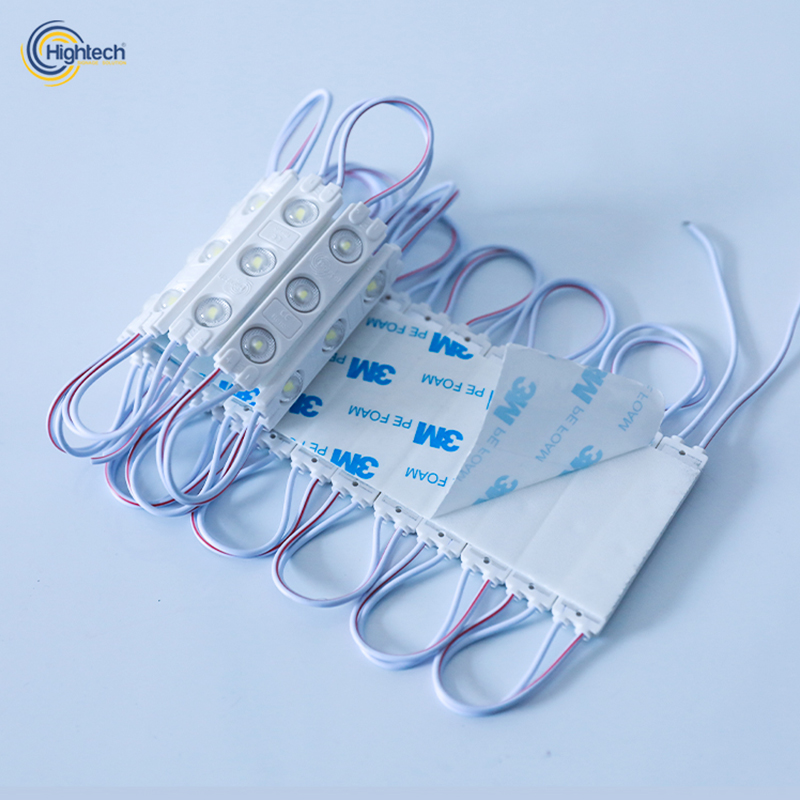

Manufactured in Xiangjiang Street South, Jinggangshan Road West, Qinghe County, Xingtai City, Hebei Province, the Hightech Injection LED module-size6414 uses an injection-molded housing (typically ABS/PC blend) with an optical-grade lens (PMMA/PC). The 2835 diode is SMT-mounted, reflowed, then mated to the lens. Potting or perimeter sealing and 3M-grade adhesive backing are used for outdoor installs.

Factory flow (condensed): incoming LED bin verification (ANSI C78.377), SMT and reflow → lens fitment → thermal pad application → sealing → 8–12 h aging at elevated temp → IP sampling to IEC 60529 → electrical safety and surge sampling (IEC 61000-4-5) → random photometry (LM-79 method). Claimed service life: L70 around 30,000–50,000 h, depending on drive current and ambient—pretty standard, and to be honest, adequate for retail cycles.

Where it fits: signage, letters, and tight spaces

- Channel letters (50–150 mm depth) needing wide, uniform wash

- Shallow lightboxes where hotspots are a pain

- Logo contours and mini-letters—small size helps

- Outdoor retail fascia; transit kiosks; POP displays

Mini case: A 2.4 m² quick-service lightbox retrofit used 60 modules of the Hightech Injection LED module-size6414 at 12 V (≈90 W total). Average plane illuminance improved from 540 lx to 760 lx, uniformity ratio tightened from 1:3.5 to 1:2.2. Installer feedback: “fewer hotspots, faster layout—less guesswork.” Not lab-grade, but matches what many customers say.

Advantages and vendor landscape

The 160° optic is the headline: fewer modules per square meter, especially in shallow cabinets. Also, 12 V at 1.5 W keeps thermal load tame, which installers appreciate in sealed boxes. Wire leads are flexible enough; adhesive is decent (I still add screws in hot climates—old habit).

| Vendor / Model | Beam | Power | Output | Waterproof | Notes |

|---|---|---|---|---|---|

| Hightech Injection LED module-size6414 | 160° | 1.5 W / 12 V | ≈130–150 lm | IP65–IP67 class | Great for shallow boxes |

| Generic A (narrow lens) | 120° | 1.2 W / 12 V | ≈90–110 lm | IP65 | More modules needed |

| Generic B (high power) | 150° | 2.0 W / 12 V | ≈160–190 lm | IP67 | Runs warmer |

Comparison based on typical published specs; verify against project requirements.

Customization and compliance

- Cable length, lead orientation, and module spacing

- CCT options (cool to neutral), CRI tuning on request

- Lens tweaks for beam shaping; branded back-adhesive

Photometric testing can follow IES LM-79 methods; LED packages typically have LM-80 data. IP testing is per IEC 60529; surge testing per IEC 61000-4-5. Ask your rep for the latest reports—I always do, especially for transit and outdoor retail bids.

Real-world feedback

Installers I spoke with liked the uniformity and the consistent binning (“less color drift from batch to batch”). One caveat: in very hot climates, they preferred mechanical fixation in addition to adhesive—wise practice for any outdoor module line.

Bottom line

For channel letters and shallow boxes, the Hightech Injection LED module-size6414 hits a sweet spot: wide beam, modest wattage, outdoor-ready. Not flashy—just solid, pragmatic engineering that makes signage look good without overthinking the layout.

- IES LM-80: Measuring Lumen Maintenance of LED Light Sources — https://www.ies.org/standards/

- IES LM-79: Electrical and Photometric Measurements of Solid-State Lighting — https://www.ies.org/standards/

- IEC 60529: Degrees of protection (IP Code) — https://webstore.iec.ch/

- IEC 61000-4-5: Surge immunity requirements — https://webstore.iec.ch/

- ANSI C78.377: Chromaticity of Solid State Lighting — https://webstore.ansi.org/

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025