J Type and Arrow Type Channel Letter Companies|OEM Quotes

Oct . 18, 2025 12:15 Back to list

J Type and Arrow Type Channel Letter Companies|OEM Quotes

What I’m Seeing in J‑Type and Arrow‑Type Channel Letter Companies Right Now

If you’ve been walking job sites lately, you’ve noticed it too: j type and arrow type channel letter companies are quietly standardizing their sealing stacks. Less guesswork, fewer callbacks. In my notebook from recent plant tours—Chicago, Shenzhen, and yes, a gritty but efficient workshop near Qinghe County—one common thread keeps popping up: smarter gasketing around trims and returns to control ingress, glare, and thermal stress.

Why trims matter (and why gaskets suddenly got interesting)

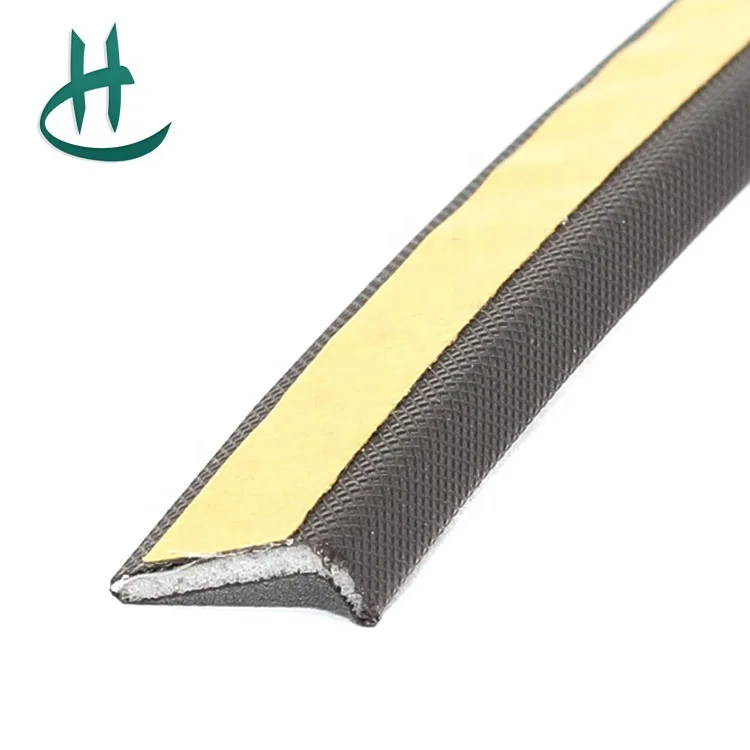

J‑type and Arrow‑type profiles cue how the acrylic face nests into the aluminum return. That geometry dictates how you manage water, dust, and thermal cycling. Many customers say the difference between a sign that lasts five years and one that hits a decade is, frankly, the rubber you can’t see. That’s where a neoprene flange gasket—custom cut—earns its keep.

Product spotlight used by j type and arrow type channel letter companies

From Xiangjiang Street South, Jinggangshan Road West, Qinghe County (Xingtai City, Hebei), a supplier I’ve followed ships a neoprene rubber gasket set—custom sizes/colors—for sealing faces and flanges. It’s not flashy, but it’s consistent, and installers like that it compresses evenly around Arrow‑type corners without “smiles.”

| Spec | Detail (≈, real‑world may vary) |

|---|---|

| Material | CR (Neoprene), ASTM D2000 classification |

| Hardness | Shore A 50 ±5 (ASTM D2240) |

| Thickness / Width | 1–10 mm / custom, die‑cut or CNC |

| Operating Temp | −30 to +100 °C continuous |

| Tensile / Elongation | ≥7 MPa / ≥250% (ISO 37) |

| Compression Set | ≤25% @70 °C, 22 h (ASTM D395) |

| UV/Weathering | ASTM G154 cycle tested; outdoor 5–8 yrs typical |

| Compliance | RoHS, REACH; supports UL 48/IP65 builds |

Process flow most j type and arrow type channel letter companies follow

- Materials: 0.8–1.2 mm aluminum returns, PMMA faces, CR gaskets, neutral‑cure silicone, UL‑listed LED modules.

- Fabrication: laser/punch, brake forming for J/Arrow profiles, TIG spot, rivet where needed.

- Gasketing: dry fit, alcohol wipe, peel‑stick PSA or channel‑bonding with light clamp pressure (≈20–30% compression).

- Electrical: UL 879 components, strain relief, 24 VDC preferred.

- Testing: IP65–67 spray or dunk; 30 kPa leak test for 15 min; Hi‑Pot per UL 48; luminance uniformity check.

In fact, one shop told me their warranty claims dropped ~18% after standardizing a single durometer across all Arrow‑type letters.

Vendor snapshot (real-world notes)

| Vendor Type | Pros | Watch‑outs |

|---|---|---|

| Boutique Fabricator | Tight tolerances for Arrow corners; color‑matched gaskets | Longer lead times |

| Volume Exporter (Hebei/Xingtai) | Cost‑effective; consistent CR sheets; quick re‑orders | Spec communication—confirm durometer, PSA brand |

| Regional Hybrid | Fast service calls; on‑site fit checks | Higher unit costs |

Use cases, feedback, and small wins

- Retail rollouts: J‑type letters on EIFS—gaskets kept IP65 after 200 h spray test.

- Fuel canopies: Arrow‑type profiles; installers liked lower compression set in summer heat.

- Customer notes: “quieter installs,” “fewer drip lines,” “no lens buzz” after cabinet cool‑downs.

Testing snapshots: Δlumen 12 N/25 mm on powder‑coat after 24 h.

Customization tips for j type and arrow type channel letter companies

Ask for corner‑relief options (kiss‑cut radii), specify Shore A by application (45A cold climates, 55A hot rooftops), and confirm compliance docs (RoHS/REACH, test coupons). For branding, color‑tinted neoprene can hide light leaks on white acrylic—surprisingly useful on shallow returns.

Where it’s made

Origin: Xiangjiang Street South, Jinggangshan Road West, Qinghe County, Xingtai City, Hebei Province. Lead times are reasonable; customs paperwork is tidy.

Citations

- UL 48 Standard for Electric Signs.

- ASTM D2000 Classification for Rubber Products in Automotive Applications.

- ISO 37 (tensile), ISO 815‑1 (compression set), ASTM D2240 (durometer).

- IEC 60529 (IP65–IP67 ingress protection) for environmental sealing targets.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025