Window Seal Strip Adhesive | Strong, Durable Sealing Solutions

Aug . 10, 2025 02:20 Back to list

Window Seal Strip Adhesive | Strong, Durable Sealing Solutions

The Critical Role and Evolving Landscape of Window Seal Strip Adhesives

In modern construction, automotive, and industrial applications, the integrity and performance of window seal strip adhesive systems are paramount, directly impacting energy efficiency, sound insulation, and structural longevity. As industries increasingly prioritize sustainability and enhanced user comfort, the demand for high-performance sealing solutions has driven significant innovation among leading window seal strip adhesive companies. These specialized manufacturers are at the forefront of developing advanced materials and sophisticated application technologies that ensure superior sealing capabilities against a myriad of environmental challenges, including extreme temperatures, moisture ingress, UV radiation, and atmospheric pollutants. The global market for window seal strip adhesives is experiencing robust growth, fueled by stringent building codes, the proliferation of electric vehicles, and a heightened awareness regarding indoor air quality and thermal performance. This growth is not merely quantitative but also qualitative, emphasizing the shift towards eco-friendly formulations, longer service life, and enhanced aesthetic integration. From residential windows requiring discreet, durable seals to complex architectural facades demanding exceptional weatherproofing, the versatility and reliability of these adhesive solutions are foundational. Furthermore, the automotive sector relies heavily on these products to mitigate noise, vibration, and harshness (NVH), ensuring a quieter and more comfortable cabin environment while also contributing to vehicle aerodynamics and fuel efficiency. Industrial applications, spanning from specialized equipment enclosures to cleanroom facilities, also depend on precision-engineered seal strip adhesives to maintain operational integrity, prevent contamination, and protect sensitive components from environmental degradation. The continuous pursuit of excellence by leading window seal strip adhesive company entities involves substantial investment in research and development, exploring novel polymers, adhesive chemistries, and manufacturing methodologies. This relentless innovation ensures that their product offerings not only meet but often exceed the evolving demands of diverse industries, contributing significantly to the performance, durability, and sustainability of a vast array of end products and structures. The intricate balance between elasticity, adhesion strength, environmental resistance, and ease of application defines the success of these critical components, making the selection of a reputable supplier a decision of strategic importance for any project or manufacturing operation.

The industry trends are increasingly pointing towards solutions that offer multi-functional benefits, such as integrated fire resistance, anti-microbial properties, and even smart features like embedded sensors for performance monitoring. Manufacturers are also focusing on optimizing the application process, developing products that allow for faster, cleaner, and more efficient installation, thereby reducing labor costs and project timelines. This involves innovations in primerless adhesion, faster curing times, and more user-friendly dispensing systems. The demand for customized solutions is also on the rise, as architects, designers, and engineers seek specific profiles, colors, and material properties to match unique project requirements or brand aesthetics. This necessitates flexible manufacturing capabilities and a strong engineering support team from window seal strip adhesive companies that can translate complex specifications into tangible products. Beyond the technical aspects, the market is also influenced by global supply chain dynamics, raw material availability, and fluctuating costs, compelling window seal strip adhesive suppliers to develop resilient procurement strategies and maintain robust inventory management systems to ensure uninterrupted supply. The competitive landscape is characterized by both large multinational corporations with extensive R&D resources and agile specialized firms capable of rapid innovation and niche market penetration. Collaboration between material science companies, adhesive formulators, and end-product manufacturers is becoming more common, fostering an ecosystem of innovation that accelerates the development and adoption of next-generation sealing technologies. The long-term performance and sustainability of structures and vehicles critically depend on the quality and durability of their sealing components, underscoring the indispensable role of expert window seal strip adhesive manufacturers in delivering reliable, cutting-edge solutions that meet the challenges of modern industrial and consumer demands.

Precision Manufacturing Processes and Rigorous Quality Assurance

The production of high-performance window seal strip adhesives by professional window seal strip adhesive factories involves a sophisticated multi-stage manufacturing process, meticulously designed to ensure superior material properties, dimensional accuracy, and consistent quality. This intricate journey begins with the careful selection of raw materials, which typically include high-grade polymers such as EPDM (Ethylene Propylene Diene Monomer), PVC (Polyvinyl Chloride), TPE (Thermoplastic Elastomer), or silicone rubber. Each material is chosen for its specific properties: EPDM offers excellent weather resistance, UV stability, and flexibility across a wide temperature range, making it ideal for outdoor applications; PVC provides good chemical resistance and cost-effectiveness, often used for interior or less demanding applications; TPE combines the processing ease of thermoplastics with the elasticity of rubber, allowing for complex profiles; and silicone boasts exceptional high-temperature resistance, UV stability, and biocompatibility, suitable for specialized environments. The manufacturing process often commences with compounding, where these base polymers are blended with various additives such as plasticizers, fillers (e.g., carbon black, silica), colorants, stabilizers (e.g., UV inhibitors, antioxidants), and processing aids. This precise formulation is crucial for achieving the desired mechanical, chemical, and aesthetic properties of the final product. Following compounding, the material typically undergoes an extrusion process, where the heated and homogenized polymer blend is forced through a die to create the continuous profile of the seal strip. Advanced extrusion techniques, such as co-extrusion, allow for the creation of multi-material profiles, combining different polymers or materials with varying hardnesses within a single strip, such as a rigid base for mounting and a soft lip for sealing. This is particularly vital for intricate designs required by modern window systems. Precision tooling and computer numerically controlled (CNC) machinery ensure exceptional dimensional accuracy and consistency throughout the production run, minimizing waste and ensuring a perfect fit in target applications.

After extrusion, the seal strips often undergo a curing or vulcanization process (for EPDM and silicone) to enhance their cross-linking and thermoset properties, thereby improving their elasticity, tensile strength, and heat resistance. For adhesive-backed strips, a specialized adhesive layer is then applied. This adhesive can be hot melt, acrylic, or silicone-based, selected based on the desired bond strength, temperature resistance, and substrate compatibility. Advanced coating technologies ensure uniform application of the adhesive, often followed by a protective release liner. Throughout all stages of manufacturing, rigorous quality control measures are implemented to meet or exceed international standards such as ISO 9001 for quality management systems and specific ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) standards for material properties. These comprehensive testing protocols include measuring physical parameters like Shore A hardness, tensile strength, elongation at break, and compression set, which are critical for predicting long-term performance. Environmental chambers are utilized for accelerated aging tests, simulating exposure to UV radiation, ozone, extreme temperatures (both high and low), and humidity to assess long-term durability and performance degradation. Dimensional inspections, using laser micrometers and optical comparators, ensure that every seal strip conforms to precise specifications, guaranteeing a proper fit and optimal sealing performance in diverse applications such as petrochemical, metallurgy, and water supply and drainage systems. The lifespan of these products, often exceeding 10-15 years under typical operating conditions, is a testament to the meticulous manufacturing and stringent testing protocols adopted by leading window seal strip adhesive companies. The direct advantages of employing such precisely manufactured seal strips include significant energy savings due to superior thermal insulation, effective corrosion prevention by sealing out moisture and chemicals, and enhanced environmental control by preventing dust and noise ingress. This holistic approach to manufacturing, from raw material sourcing to final product inspection, ensures that each seal strip not only meets but surpasses the stringent demands of modern industrial and consumer applications, providing reliable, long-lasting performance and contributing significantly to the overall efficiency and durability of the systems they are integrated into.

Technical Specifications and Performance Benchmarks of Leading Window Seal Strip Adhesives

Understanding the technical specifications and performance benchmarks is crucial when evaluating the offerings from various window seal strip adhesive suppliers. The efficacy of a window seal strip adhesive product is determined by a complex interplay of material properties, adhesive type, and design geometry, all engineered to withstand specific operational environments and provide optimal sealing performance. Key parameters include the material composition, which dictates resistance to UV, ozone, and chemicals, as well as flexibility and compression set characteristics. For instance, high-quality EPDM formulations offer superior resistance to weathering and extreme temperatures (typically -40°C to +120°C), making them ideal for exterior applications where durability is paramount. Silicone-based seals excel in even higher temperature ranges (up to +200°C or more) and provide exceptional UV resistance, often used in specialized industrial or high-performance architectural projects. Hardness, measured in Shore A, indicates the material's resistance to indentation and affects its compression capabilities and long-term sealing force; typical values range from 40 to 80 Shore A depending on the application requirement. Tensile strength and elongation at break are vital mechanical properties that define the material's ability to resist tearing and stretching without permanent deformation, ensuring the seal maintains its integrity under stress. A higher tensile strength (e.g., 5-15 MPa) combined with good elongation (e.g., 200-500%) indicates a robust and flexible material. Furthermore, the type of adhesive used plays a pivotal role in the bond strength, application versatility, and resistance to environmental factors. Acrylic adhesives offer excellent long-term durability, good resistance to plasticizers, and strong adhesion to various substrates over a wide temperature range. Hot melt adhesives provide quick setting times for high-volume manufacturing, while silicone adhesives offer superior performance in high-temperature and harsh chemical environments. Leading window seal strip adhesive companies invest significantly in developing proprietary adhesive formulations to optimize specific performance characteristics, such as peel strength, shear strength, and tack, under varying environmental conditions.

| Parameter | EPDM Rubber | Silicone Rubber | PVC (Flexible) | TPE |

|---|---|---|---|---|

| Density (g/cm³) | 1.1 - 1.4 | 1.1 - 1.3 | 1.2 - 1.5 | 0.9 - 1.2 |

| Hardness (Shore A) | 40 - 80 | 30 - 70 | 50 - 90 | 40 - 90 |

| Tensile Strength (MPa) | 5 - 15 | 4 - 10 | 10 - 20 | 5 - 25 |

| Elongation at Break (%) | 200 - 500 | 100 - 400 | 150 - 350 | 200 - 600 |

| Service Temperature (°C) | -40 to +120 | -60 to +200 | -20 to +60 | -50 to +120 |

| UV Resistance | Excellent | Excellent | Good | Good to Excellent |

| Ozone Resistance | Excellent | Excellent | Poor to Fair | Good to Excellent |

| Water Absorption | Low | Very Low | Low | Very Low |

| Typical Adhesive Type | Acrylic, Hot Melt | Silicone, Acrylic | Acrylic, Hot Melt | Acrylic, Hot Melt |

Beyond these material-specific parameters, performance is also measured by the seal's ability to maintain a consistent compression set over time – a critical factor for long-term weatherproofing and energy efficiency. A low compression set indicates that the material will return to its original shape after prolonged compression, maintaining its sealing force. For a window seal strip adhesive manufacturer aiming for excellence, comprehensive testing against industry standards, such as ASTM E283 for air leakage, ASTM E331 for water penetration, and ASTM E413 for sound transmission class (STC), provides authoritative proof of performance. These tests evaluate how well the installed seal strip performs in real-world conditions, preventing air, water, and noise ingress. The long-term durability is often expressed through accelerated weathering tests, which simulate years of outdoor exposure in controlled laboratory environments. Data from such tests, including changes in tensile strength, elongation, and color, provide valuable insights into the expected service life and resistance to environmental degradation. By meticulously analyzing these technical specifications and performance benchmarks, architects, engineers, and procurement managers can make informed decisions, selecting window seal strip adhesive products that not only meet the immediate project requirements but also offer long-term reliability and cost-effectiveness. Reputable window seal strip adhesive companies will readily provide detailed technical data sheets, test reports, and certifications (e.g., ISO 9001 for quality management, specific product certifications from recognized testing bodies) to substantiate their claims, ensuring transparency and building customer trust. The robust performance parameters are a direct result of the advanced material science and precision engineering employed throughout the manufacturing process, guaranteeing that the final product delivers on its promise of superior sealing, insulation, and durability.

Diverse Application Scenarios and Tangible Benefits Across Industries

The versatility and high performance of window seal strip adhesives enable their critical deployment across an extensive array of application scenarios, delivering significant tangible benefits in each domain. In the construction and architectural sectors, these seals are indispensable for both residential and commercial buildings. They are expertly integrated into windows, doors, curtain walls, and skylights to create an airtight and watertight barrier, drastically reducing energy consumption for heating and cooling. By preventing conditioned air from escaping and unconditioned air from entering, they contribute directly to substantial energy savings, aligning with global sustainability goals. For instance, in a modern high-rise commercial building, meticulously sealed windows can account for up to 20-30% reduction in HVAC energy load, translating into considerable operational cost savings over the building's lifespan. Beyond energy efficiency, these seals provide superior sound insulation, effectively mitigating external noise pollution in urban environments, thereby enhancing indoor comfort and productivity. They also prevent the ingress of dust, pollutants, and insects, ensuring a cleaner and healthier indoor environment. In the automotive industry, window seal strip adhesives are vital components for enhancing vehicle performance, safety, and passenger comfort. They are strategically used around windshields, side windows, and rear windows, as well as on door frames and sunroofs. Their primary roles include sealing out water and air, reducing wind noise, and dampening vibrations (NVH - Noise, Vibration, and Harshness) for a quieter ride. Modern automotive seal strips are engineered to withstand extreme temperatures, UV radiation from sunlight, and various chemicals encountered on roads, ensuring long-term durability and structural integrity for the vehicle's glass components. The sophisticated designs contribute to improved vehicle aerodynamics, leading to enhanced fuel efficiency, a critical factor for both traditional combustion engine vehicles and emerging electric vehicles.

In the marine industry, where exposure to harsh saltwater environments, extreme humidity, and constant motion is the norm, the demand for robust and corrosion-resistant window seal strip adhesives is particularly high. These seals are used on boat windows, hatches, and portholes to prevent water ingress, protect interior components from damage, and ensure the safety of occupants. The anti-corrosive properties of specialized EPDM or silicone seals are paramount in preventing degradation of surrounding metal frames. Similarly, in industrial applications, such as those in petrochemical plants, metallurgical facilities, or water treatment infrastructure, window seal strip adhesives are employed in control rooms, equipment enclosures, and processing units. Here, their ability to resist aggressive chemicals, high temperatures, and maintain integrity in dusty or corrosive atmospheres is crucial for operational reliability and safety. For instance, in a cleanroom environment, precise seals are essential to maintain positive or negative pressure differentials and prevent particulate contamination, ensuring product purity and process integrity. The advantages extend beyond mere sealing; for example, in HVAC systems, these products ensure efficient airflow and prevent leakage in ductwork and air handling units, directly contributing to system efficiency and preventing moisture-related issues like mold growth. The inherent flexibility and conformability of these adhesive strips also allow for easy installation around irregular shapes and varying gaps, simplifying complex sealing challenges. The contribution of these sealing solutions to "energy saving" is multifaceted, ranging from reducing heating and cooling loads in buildings to improving the aerodynamic efficiency of vehicles. The "anti-corrosion" benefit stems from their ability to create an impenetrable barrier that prevents moisture and corrosive agents from reaching vulnerable substrates, thereby extending the lifespan of window frames and associated structures. Leading window seal strip adhesive companies understand these diverse needs and continually innovate to provide specialized products that cater to the unique demands of each industry, demonstrating unparalleled expertise and experience in delivering solutions that offer long-term value and superior performance in even the most challenging environments.

Strategic Selection: Comparing Leading Window Seal Strip Adhesive Manufacturers

Choosing the right partner among the myriad of window seal strip adhesive companies is a strategic decision that directly impacts the long-term performance, cost-effectiveness, and reliability of your products or projects. While many entities claim expertise, discerning the true leaders requires a comprehensive evaluation based on several critical criteria. Foremost among these is the manufacturer's R&D capability and commitment to innovation. Top-tier window seal strip adhesive manufacturers consistently invest in material science, adhesive chemistry, and manufacturing process improvements. This includes developing new polymer formulations that offer enhanced resistance to specific environmental stressors (e.g., extreme UV, aggressive chemicals), or creating more environmentally friendly solutions (e.g., low VOC adhesives, recyclable materials). Their ability to anticipate and respond to evolving industry standards and market demands, such as the increasing push for energy-efficient or fire-retardant materials, is a strong indicator of their leadership. Secondly, evaluate their production capacity and technological infrastructure. A leading window seal strip adhesive factory should possess state-of-the-art extrusion lines, advanced adhesive application systems, and robust quality control laboratories. This ensures not only high-volume production but also consistent product quality and dimensional accuracy across batches. Manufacturers with extensive automation and precision machinery are better equipped to handle complex profiles and maintain tight tolerances, which are critical for optimal sealing performance. A company's certifications, such as ISO 9001 for quality management, ISO 14001 for environmental management, and specific product certifications from independent testing bodies (e.g., UL, CE, ASTM compliant), serve as authoritative proof of their adherence to stringent international standards. These certifications are not merely badges but represent a verifiable commitment to quality, reliability, and continuous improvement throughout their operations.

Another crucial aspect for comparison is the scope of their product portfolio and their customization capabilities. While some window seal strip adhesive companies offer a standardized range, true industry leaders provide extensive customization options for profiles, materials, colors, and adhesive types. This flexibility is essential for clients with unique design requirements or specialized application challenges. Their engineering and design support team should be capable of collaborating closely with clients from concept to production, offering expert advice on material selection, profile optimization, and adhesive compatibility. For businesses requiring global supply chains, assessing the reach and efficiency of window seal strip adhesive exporters is paramount. A reliable exporter should demonstrate proven logistics expertise, efficient customs clearance processes, and responsive international customer support to ensure timely and cost-effective delivery worldwide. Customer service and after-sales support also differentiate top-tier suppliers. This includes responsive technical assistance, clear warranty policies, efficient problem resolution, and a willingness to provide detailed technical data and application guidelines. Reviewing case studies, client testimonials, and industry recognition (e.g., awards, long-term partnerships with reputable firms) can offer valuable insights into a company's experience and trustworthiness. Furthermore, obtaining clear and transparent window seal strip adhesive quotes that detail all costs, lead times, and terms of service is essential for a comprehensive comparison. Finally, consider the company's approach to sustainability and corporate social responsibility. Leading manufacturers are increasingly adopting eco-friendly practices, from raw material sourcing to waste management, which not only benefits the environment but also aligns with the values of many modern businesses and consumers. By meticulously evaluating these facets, businesses can forge partnerships with window seal strip adhesive suppliers that not only deliver high-quality products but also offer robust support, innovative solutions, and a commitment to long-term success, ensuring that their window sealing needs are met with unparalleled expertise and reliability.

Bespoke Solutions: Customization and Advanced Engineering for Specific Needs

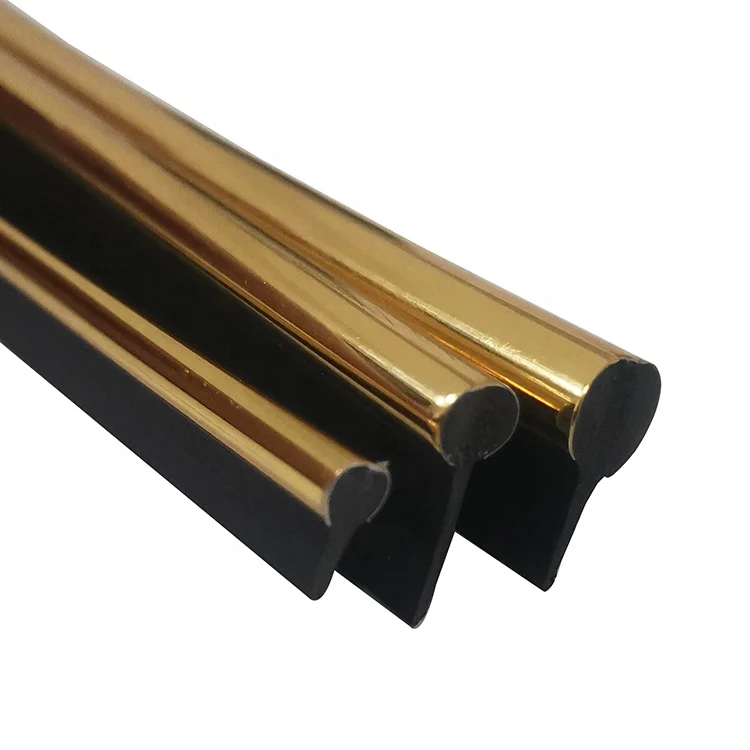

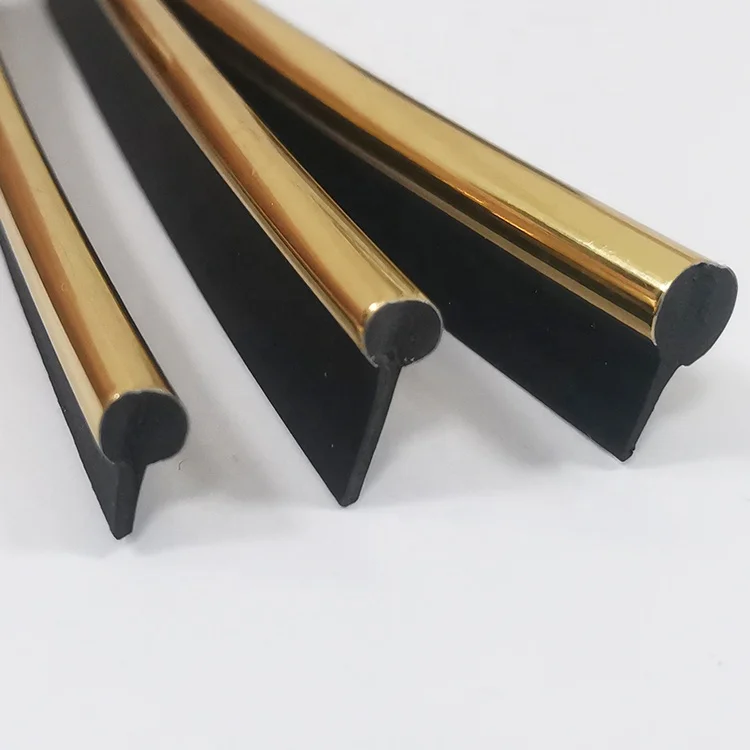

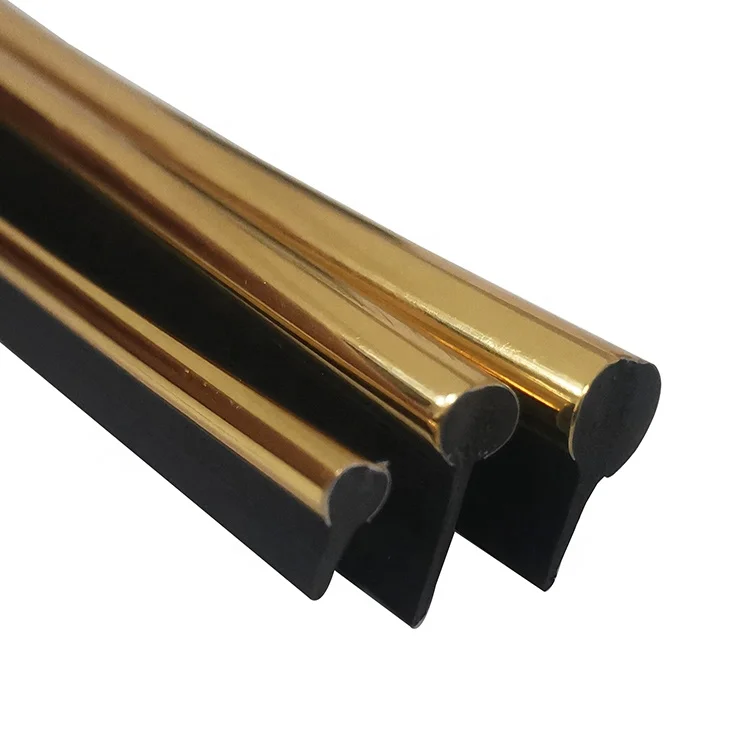

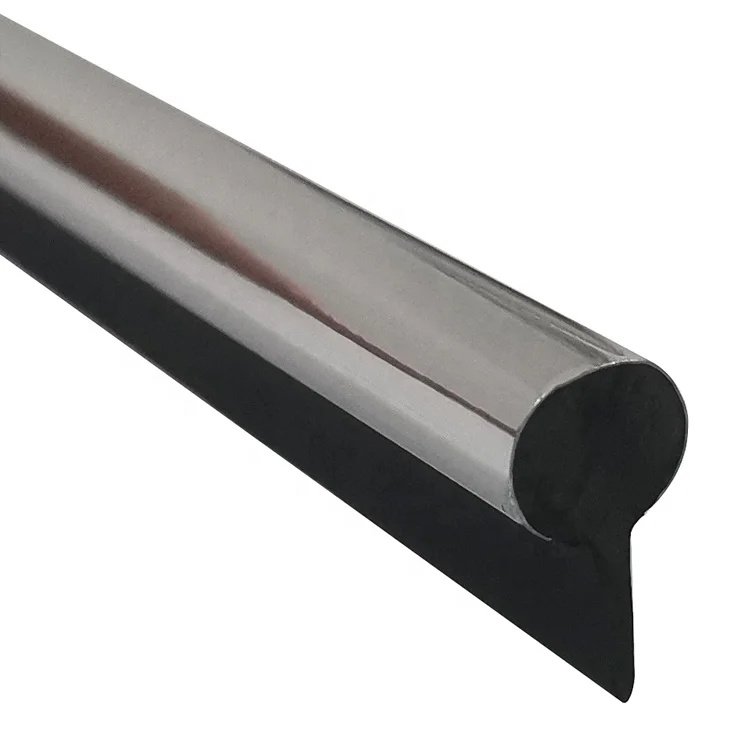

In an era where differentiation and optimized performance are paramount, the ability of window seal strip adhesive companies to provide highly customized solutions is a significant competitive advantage. While standard profiles cater to many general applications, numerous projects demand bespoke designs to achieve specific aesthetic integration, unparalleled sealing performance, or compliance with unique regulatory requirements. For example, the product mentioned, the Customized Sizes Colorful Flexible Sofa and Furniture Chrome Gold PVC Plastic Edging Strip (Product URL: `https://www.pulongte.com/customized-sizes-colorful-flexible-sofa-and-furniture-chrome-gold-pvc-plastic-edging-strip.html`), exemplifies a manufacturer's proficiency in creating tailored extrusion and material solutions beyond standard sealing, showcasing their versatility in meeting diverse market needs. This capability translates directly to specialized window seal strips where custom dimensions, complex geometries, and unique material properties are often critical. The customization process typically begins with an in-depth consultation, where the client's precise requirements, including application environment, performance targets (e.g., specific temperature ranges, chemical exposure, required compression force), aesthetic preferences (e.g., color matching, surface finish), and regulatory compliance needs, are thoroughly documented. Expert engineers from the window seal strip adhesive factory then leverage advanced CAD/CAM software to design the custom profile, ensuring optimal fit and function within the intended window system. This design phase often involves iterative prototyping, allowing for physical testing and refinement to validate the design's effectiveness before mass production. Material selection is another critical aspect of customization. Beyond standard EPDM, silicone, PVC, or TPE, specialized compounds can be formulated to impart specific properties such as enhanced fire resistance (meeting UL 94 V-0 standards), superior chemical compatibility for industrial applications, or improved acoustic damping for noise-sensitive environments. Furthermore, adhesive types can be customized, ranging from high-tack acrylics for rapid bonding to specialized silicone-based adhesives for extreme temperature resistance or specific substrate adhesion.

The implementation of advanced manufacturing processes, such as multi-durometer co-extrusion, allows for the creation of seals with varying hardness zones within a single profile, optimizing both sealing effectiveness and ease of installation. For example, a harder spine can provide structural rigidity for mounting, while softer lips ensure an excellent compression seal against the window frame. Laser cutting and precision slitting technologies further enable the production of highly intricate shapes and precise lengths, minimizing waste and simplifying assembly processes for end-users. The role of technical support and collaborative engineering is paramount in the success of custom projects. Leading window seal strip adhesive manufacturers provide dedicated engineering teams who work hand-in-hand with clients, offering invaluable expertise from concept development through to production. This includes providing detailed performance data, conducting application-specific testing, and offering guidance on installation best practices. For large-scale projects or complex industrial applications, this level of partnership ensures that the customized sealing solution performs exactly as required, contributing to significant improvements in product quality, operational efficiency, and long-term durability. For instance, an automotive OEM might require a custom window seal strip with integrated flocking for reduced friction and noise, coupled with specific resistance to engine fluids. A custom solution from a specialized window seal strip adhesive company can address these multifaceted requirements perfectly. The capacity for innovative problem-solving and the flexibility to adapt production lines for unique specifications underscore the advanced capabilities that define a top-tier supplier in this field. This commitment to bespoke engineering solutions not only enhances product performance but also builds strong, enduring relationships based on trust, mutual understanding, and shared success in navigating the most demanding sealing challenges, solidifying their position as go-to window seal strip adhesive suppliers in the global market.

Building Trust: Warranty, Delivery, and Comprehensive Customer Support

Trust is the cornerstone of any successful B2B relationship, especially when dealing with critical components like window seal strip adhesives where long-term performance directly impacts end-product quality and client satisfaction. Leading window seal strip adhesive companies distinguish themselves not only through product excellence but also through their unwavering commitment to customer support, transparent delivery protocols, and robust warranty commitments. A comprehensive quality assurance framework, typically evidenced by ISO 9001 certification, is fundamental. This certification assures clients that the manufacturer adheres to globally recognized standards for quality management, encompassing everything from raw material procurement and production processes to final inspection and delivery. Beyond general certifications, product-specific testing and compliance with relevant industry standards (e.g., ASTM, DIN, UL) provide further layers of authority and trustworthiness, verifying the seal strips' performance in terms of air leakage, water penetration, UV resistance, and durability under various environmental conditions. When inquiring for window seal strip adhesive quotes, it is crucial to request not only pricing but also detailed technical data sheets, test reports, and copies of relevant certifications. This transparency empowers buyers to make informed decisions based on verified performance rather than mere claims. Reputable manufacturers will offer clear, unambiguous warranty commitments that cover defects in materials and workmanship for a specified period, typically ranging from 5 to 15 years, reflecting their confidence in product longevity. This warranty provides essential peace of mind, mitigating risks for both the direct buyer and the end-user of the final product.

Delivery schedules and logistics are another critical factor, particularly for window seal strip adhesive exporters serving a global clientele. Efficient order processing, precise lead time estimation, and reliable international shipping capabilities are paramount to ensuring projects stay on schedule and inventory levels are maintained. Companies with established global distribution networks and experience in managing complex customs requirements can significantly reduce logistical hurdles and unexpected delays. Many top window seal strip adhesive companies offer comprehensive technical support, providing expert guidance on product selection, application methods, installation techniques, and troubleshooting. This support can range from pre-sales consultations and engineering advice during the design phase to post-sales assistance for any performance issues or queries. A dedicated customer service team capable of providing prompt and knowledgeable responses builds immense trust and strengthens the partnership. Furthermore, effective communication channels, including online portals, direct phone lines, and responsive email support, ensure that client inquiries are addressed swiftly and efficiently. To further demonstrate trustworthiness and provide immediate answers to common concerns, many companies integrate comprehensive FAQ (Frequently Asked Questions) modules on their platforms. For instance:

- Q: What is the typical lifespan of your window seal strip adhesives?

A: Our products are engineered for longevity, with an expected service life of 10-15 years under normal operating conditions, backed by extensive accelerated aging tests and field performance data. - Q: Are your seal strips resistant to specific chemicals or extreme weather?

A: Yes, we offer specialized formulations (e.g., EPDM, Silicone) designed for superior resistance to UV radiation, ozone, extreme temperatures (-60°C to +200°C), and a range of industrial chemicals. Specific resistance data is available in our technical data sheets. - Q: Can you provide custom profiles or colors for our unique project?

A: Absolutely. Customization is a core strength. Our engineering team can work with you to design specific profiles, match colors, and formulate materials to meet precise project requirements. - Q: What is your typical lead time for large orders?

A: Lead times vary based on product complexity and order volume. For standard products, it's typically 3-4 weeks. For custom orders, a detailed timeline will be provided after design finalization, generally ranging from 6-10 weeks. - Q: Do you offer samples for testing before bulk purchase?

A: Yes, we encourage clients to request samples for testing and evaluation to ensure our products meet their exact application needs. - Q: How do your products contribute to energy efficiency?

A: Our seal strips significantly reduce air infiltration and exfiltration, thereby minimizing heat loss in winter and heat gain in summer, leading to substantial energy savings in heating and cooling costs for buildings and vehicles.

Future Outlook and Innovation in Window Seal Strip Adhesives

The landscape of window seal strip adhesives is continuously evolving, driven by advancements in material science, increasingly stringent environmental regulations, and the demand for higher performance and smart functionalities. The future outlook for window seal strip adhesive companies is characterized by several key innovation trends that will reshape product development and application. One significant trend is the development of "smart" seals. These next-generation products might incorporate embedded sensors to monitor seal integrity, detect moisture ingress, or provide real-time data on temperature and pressure differentials across the window system. This level of predictive maintenance capability could revolutionize facility management and energy auditing in large commercial buildings, allowing for proactive replacement or repair before significant energy loss occurs. Another area of intensive research is self-healing materials. Imagine a seal strip that can automatically repair minor punctures or tears, significantly extending its lifespan and reducing maintenance requirements. While still in its nascent stages for this specific application, breakthroughs in polymer chemistry are making such concepts increasingly feasible. Furthermore, the push towards greater sustainability is accelerating the adoption of eco-friendly materials and manufacturing processes. This includes the use of bio-based polymers, recycled content, and materials that are fully recyclable at the end of their service life, reducing the overall carbon footprint. Low VOC (Volatile Organic Compound) adhesives and solvent-free formulations are becoming standard, addressing concerns about indoor air quality and worker safety. Manufacturers are also exploring innovative production techniques, such as additive manufacturing (3D printing) for complex, customized seal profiles, which could enable rapid prototyping and on-demand production, reducing lead times and waste.

Beyond materials, advancements in adhesive technology are focused on achieving stronger, more durable bonds with diverse substrates, while also allowing for easier removal or repositioning during installation. This includes primer-less adhesion solutions that simplify application and reduce overall project time and cost. The integration of advanced surface treatment technologies to enhance adhesion to challenging materials, such as specific plastics or coated metals, is also a key area of development for window seal strip adhesive companies. The growing market for smart homes and automated building systems will also drive demand for seal strips that are compatible with advanced building envelopes and intelligent climate control systems, contributing to a truly integrated and efficient living or working environment. In the automotive sector, the increasing prevalence of electric vehicles (EVs) introduces new challenges and opportunities. EVs require exceptional sound insulation due to the absence of engine noise, placing greater demands on NVH-reducing seal strips. Additionally, the lighter materials used in EV construction necessitate adhesives that can bond effectively to these new substrates without compromising structural integrity. Leading window seal strip adhesive factories are actively engaging in collaborative research with automotive OEMs to develop seals that meet these unique requirements. The competitive landscape will likely see increased mergers and acquisitions as companies seek to expand their technological capabilities, market reach, and product portfolios. This consolidation will foster a more integrated supply chain, potentially leading to more comprehensive solutions for end-users. Ultimately, the future of window seal strip adhesives lies in the continuous pursuit of multi-functional, intelligent, and sustainable solutions that not only meet but exceed the evolving demands of a rapidly changing world, solidifying the indispensable role of expert window seal strip adhesive suppliers in driving efficiency, comfort, and environmental responsibility across industries.

Conclusion: Partnering with Leading Window Seal Strip Adhesive Experts

In conclusion, the sophisticated engineering and meticulous manufacturing behind modern window seal strip adhesives underscore their indispensable role in countless applications, from ensuring energy efficiency in architectural marvels to enhancing acoustic comfort in the latest automotive designs. The journey from raw polymer to a high-performance seal strip involves intricate processes, stringent quality control, and a deep understanding of material science and adhesive chemistry. As highlighted, selecting a proficient partner among window seal strip adhesive companies is not merely a purchasing decision but a strategic investment in long-term performance, reliability, and cost-effectiveness. A leading window seal strip adhesive manufacturer distinguishes itself through robust R&D, advanced production capabilities, comprehensive quality certifications (such as ISO 9001, ASTM, DIN), and a steadfast commitment to customer-centric innovation. Their capacity to offer tailored solutions, whether through custom profiles, specialized material formulations, or specific adhesive types, addresses the unique demands of diverse industries and complex project requirements. Furthermore, transparent communication, efficient global logistics from expert window seal strip adhesive exporters, clear warranty policies, and proactive technical support are hallmarks of a trustworthy supplier, ensuring seamless collaboration and peace of mind for clients. The tangible benefits derived from high-quality window seal strip adhesives — including significant energy savings, enhanced noise reduction, superior weatherproofing, and extended product lifespans — translate directly into improved operational efficiency, reduced maintenance costs, and increased end-user satisfaction. As industries continue to evolve, driven by demands for greater sustainability, smart functionality, and enhanced performance, the innovation trajectory of window seal strip adhesive companies promises even more advanced and integrated sealing solutions. Partnering with a recognized leader in this field means leveraging unparalleled expertise and a proven track record to achieve optimal outcomes for your most critical sealing challenges.

The continuous pursuit of excellence and innovation by professional window seal strip adhesive suppliers ensures that they remain at the vanguard of providing materials that not only seal but also enhance the overall performance, durability, and environmental footprint of the structures and products they are integrated into. By focusing on technical parameters, application versatility, and the total value proposition, businesses can confidently select a partner capable of delivering solutions that meet today's rigorous demands and anticipate tomorrow's challenges.

References and Further Reading:

- ASTM International Standards on Rubber Products. (Reference for material testing standards relevant to seal strips.)

- ISO 9001: Quality management systems – Requirements. (Global standard for quality management systems.)

- Whole Building Design Guide (WBDG): Air Barriers. (Discusses the importance of sealing in building energy efficiency, relevant for window seals.)

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025