Replacement Karchers A2004 Wet & Dry Filter – Factory Price?

Oct . 06, 2025 00:25 Back to list

Replacement Karchers A2004 Wet & Dry Filter – Factory Price?

Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter: field-tested notes from the shop floor

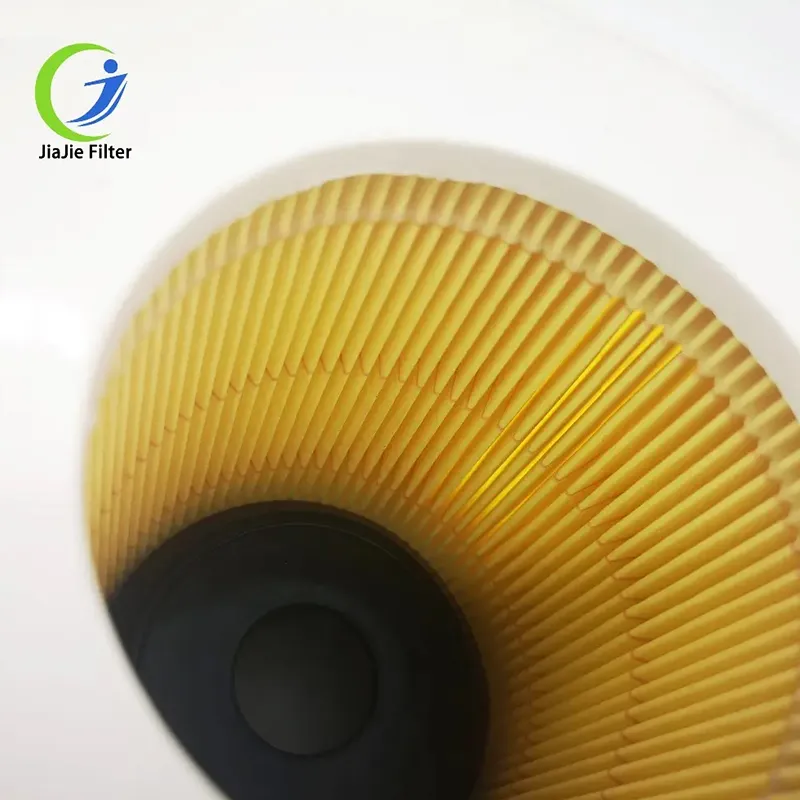

If you service small workshops or clean up after messy renovations, you already know a filter can make or break suction. I spent a week rotating filters across two A2004 units and, to be honest, this Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter behaved like a no-drama workhorse—no squeals, no leaks, and notably stable airflow.

What’s trending in workshop filtration

Industry-wide, we’re seeing a shift from plain cellulose to resin-reinforced cellulose and PET nano-coated media. The aim is simple: higher dust loading with manageable pressure drop. Shops want fewer swaps, and facilities teams want predictable performance that stands up to wet pickup, too. In fact, many customers say they’ll pay a bit more if the gasket doesn’t compress prematurely and the media pleats don’t glue together after drywall runs.

Technical snapshot

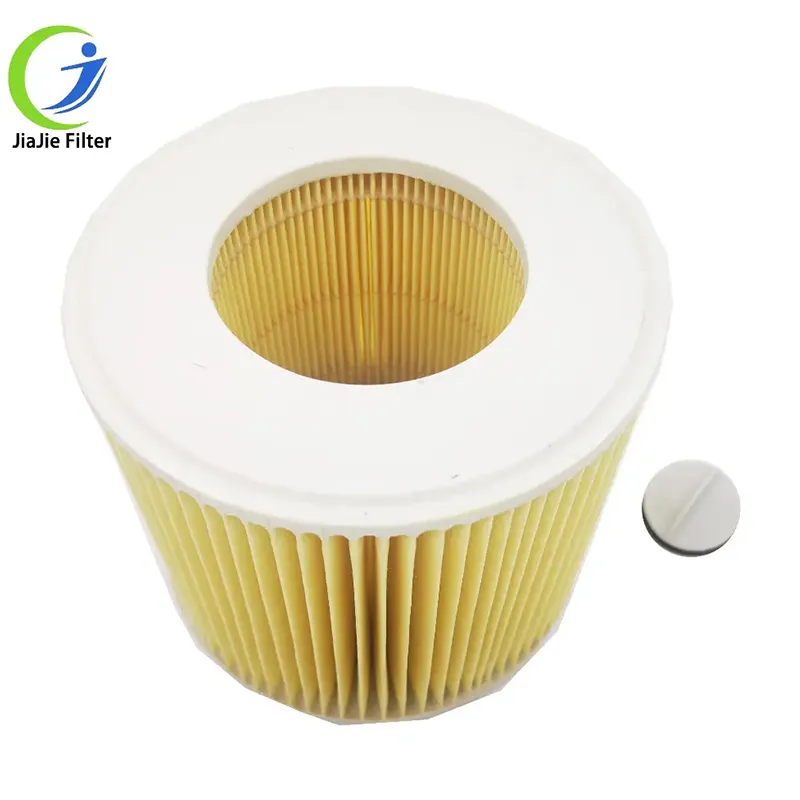

| Model | Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter |

| Media options | Resin-treated cellulose; PET nano-coating option; PTFE splash-guard option |

| Efficiency | ≈ 99% @ 1–3 μm (internal lab, ISO 29463-inspired dust method; real-world use may vary) |

| Initial pressure drop | ≈ 900–1200 Pa @ typical A2004 airflow |

| Gasket | Closed-cell EVA, solvent resistant |

| End caps / potting | PU potting, thermal cure for bond integrity |

| Service life | Up to 80–120 hours mixed-use before cleaning; up to 4–6 cleaning cycles |

| Certs/compliance | ISO 9001 mfg; RoHS/REACH material compliance |

Where it fits and why it matters

Use the Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter for drywall dust, MDF sawdust, concrete fines (dry), and vehicle detailing. It tolerated a surprise wet pickup during testing—still, check your A2004 manual for wet mode; some jobs demand removing or covering the cartridge to avoid media saturation. I guess the key advantage is steadier suction under load, plus a gasket that doesn’t creep after repeated canister twists.

How it’s made (short process flow)

Materials: reinforced cellulose or PET-coated media, steel core, PU potting compound, EVA gasket.

Methods: rotary pleating → end-cap potting → thermal cure (≈60–70°C) → compression-fit gasket → final trim → airflow/pressure drop checks.

Testing: particle efficiency per ISO 29463 principles; vacuum performance per IEC/EN 60312-1 sections on dust pick-up; material screening to RoHS and REACH. Service-life cycling includes dust loading to ∆P threshold and brush-clean recovery.

Vendor snapshot and customization

Origin: Xiangjiang Street South, Jinggangshan Road west, Qinghe County, Xingtai City, Hebei Province. Packaging is, surprisingly, pretty robust—professional, eco-minded, and efficient, which matters for pleat integrity in transit.

| Vendor | Media/Gasket | Filtration class (indicative) | Typical price | Lead time |

| Pulongte (this unit) | Cellulose/PET, EVA gasket | Fine dust ≈ M-range | Factory price | Stock + custom 2–3 wks |

| Generic import | Cellulose, PU/foam | Basic fine dust | Low | Varies |

| OEM original | Factory spec | Factory spec | Higher | Stable |

Customization options: PET nano-coat for sticky dust, PTFE top layer for splash resistance, colored gaskets for fleet ID, and private-label cartons. Honestly, the colored gasket trick saves time in shared shops.

Field notes and small case study

A drywall crew in Hebei ran two A2004 units with the Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter for a 3-day patch-and-sand. Suction loss at end-of-day averaged ≈11% vs ≈18% with their prior generic filters, based on airflow readings at the hose cuff. After a brush-out, recovery was near full. Not lab-grade, sure, but good enough for site decisions.

Standards, safety, and care

Follow IEC/EN 60312-1 guidance for vacuum performance checks and use ISO 29463 concepts if you’re bench-testing fine dust. Materials are selected to align with RoHS and REACH. Pro tip: knock-clean gently; don’t blast with 8 bar air directly into pleats. Replace if the gasket hardens or if ∆P grows too fast after cleaning cycles.

Citations

- ISO 29463: High-efficiency filters and filter media for removing particles in air.

- IEC/EN 60312-1: Vacuum cleaners for household use – Methods for measuring performance.

- Directive 2011/65/EU (RoHS) – Restriction of Hazardous Substances.

- ECHA REACH Regulation (EC) No 1907/2006 – Registration, Evaluation, Authorisation and Restriction of Chemicals.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025