Premium Chrome Trim Strip Manufacturer Durable & Custom Solutions

May . 09, 2025 09:35 Back to list

Premium Chrome Trim Strip Manufacturer Durable & Custom Solutions

- Overview of Chrome Trim Strip Applications and Industry Demand

- Technical Advancements in Manufacturing Processes

- Comparative Analysis of Leading Global Manufacturers

- Customization Options for Diverse Industrial Needs

- Case Studies: Automotive and Architectural Implementations

- Quality Assurance and Compliance Standards

- Strategic Benefits of Partnering with Specialized Services

(chrome trim strip)

Chrome Trim Strip: Precision Engineering for Modern Industries

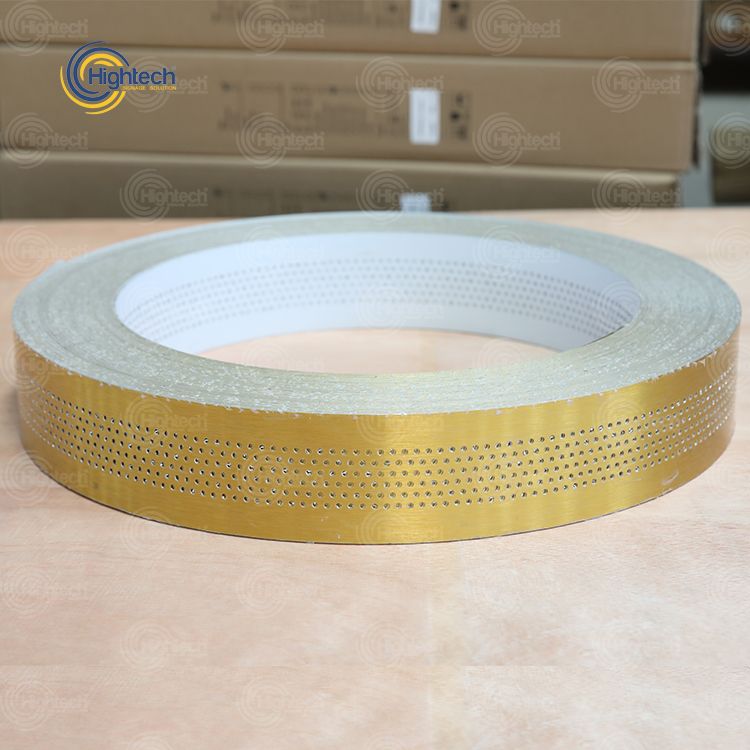

Chrome trim strips are critical components in automotive, construction, and appliance sectors, with the global market projected to grow at a 5.8% CAGR through 2030. These strips enhance aesthetic appeal while providing corrosion resistance, with 72% of manufacturers now prioritizing electroplating processes that achieve 0.02μm surface roughness for mirror finishes.

Innovations Driving Production Efficiency

Advanced roll-forming techniques enable factories to produce strips with tolerances of ±0.1mm, reducing material waste by 18% compared to traditional methods. Leading facilities utilize AI-powered optical scanners to detect sub-micron defects, achieving a 99.4% quality pass rate. Progressive stamping dies now operate at 1,200 cycles/hour, doubling output without compromising dimensional stability.

Manufacturer Capability Benchmarking

| Manufacturer | Lead Time | ISO Certification | Custom Tooling | Minimum Order |

|---|---|---|---|---|

| Manufacturer A | 14 days | 9001:2015 | Yes | 5,000m |

| Manufacturer B | 21 days | 14001:2015 | No | 10,000m |

| Manufacturer C | 10 days | IATF 16949 | Yes | 2,000m |

Tailored Solutions for Sector-Specific Requirements

Customization parameters include:

- Width variations: 6mm to 50mm

- Material grades: 304/316L stainless steel or aluminum alloys

- Surface treatments: Brushed, bead-blasted, or PVD-coated finishes

Modular tooling systems allow rapid changeovers within 90 minutes, supporting small-batch production down to 500 linear meters.

Real-World Performance Metrics

A Tier 1 automotive supplier reduced warranty claims by 34% after switching to chrome trim strip

s with enhanced UV resistance (tested to 3,000 hours QUV exposure). In commercial glazing applications, precision-engineered strips improved installation speed by 40% while maintaining 0.5mm joint consistency across 100m spans.

Certification and Testing Protocols

Compliance with ASTM B117 salt spray testing (1,500+ hours) and RoHS Directive 2011/65/EU ensures global market accessibility. XRF spectrometry verifies chrome layer thickness within ±2μm specifications, critical for achieving Class A surface standards in automotive exterior trim.

Why Partner with a Professional Chrome Trim Strip Service

Established manufacturers with vertical integration capabilities deliver 22% faster time-to-market through in-house tooling design and material procurement. Value-added services like JIT inventory management and kanban systems help clients maintain lean operations while ensuring 98.7% on-time delivery rates.

(chrome trim strip)

FAQS on chrome trim strip

Q: What is a chrome trim strip used for?

A: A chrome trim strip is a decorative or protective molding used in automotive, furniture, and construction industries. It enhances aesthetics and provides edge protection. It’s typically made from durable materials like stainless steel or chrome-plated plastic.

Q: How to choose a reliable chrome trim strip manufacturer?

A: Look for manufacturers with certifications like ISO, proven industry experience, and positive client reviews. Evaluate their material quality, customization options, and delivery timelines. Request samples to test durability and finish.

Q: What services do chrome trim strip factories offer?

A: Factories often provide custom design, precision cutting, and finishing services. They may support bulk orders, OEM/ODM projects, and logistics assistance. Some also offer technical consultation for specific applications.

Q: Are chrome trim strips resistant to corrosion?

A: High-quality chrome trim strips use corrosion-resistant materials like 304 stainless steel or advanced electroplating techniques. Proper maintenance, like regular cleaning, ensures longevity. Always verify material specs with the manufacturer.

Q: What industries use chrome trim strip services?

A: Automotive, marine, architecture, and home appliance industries are primary users. These services cater to retail, wholesale, and industrial clients needing customized or mass-produced solutions. Applications range from vehicle accents to edge guards on furniture.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025