Window Seal Strip Adhesive Companies | Fast Quotes & OEM

Nov . 05, 2025 02:10 Back to list

Window Seal Strip Adhesive Companies | Fast Quotes & OEM

Window Seal Strip Adhesive Companies is a key solution in the manufacturing industry, specifically within plastic product industry and Manufacturing of plastic profiles and strips. This article explores how Hebei Pulongte Rubber And Plastic Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Window Seal Strip Adhesive Companies Overview

- Benefits & Use Cases of Window Seal Strip Adhesive Companies in Manufacturing of plastic profiles and strips

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Window Seal Strip Adhesive Companies from Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

Window Seal Strip Adhesive Companies Overview

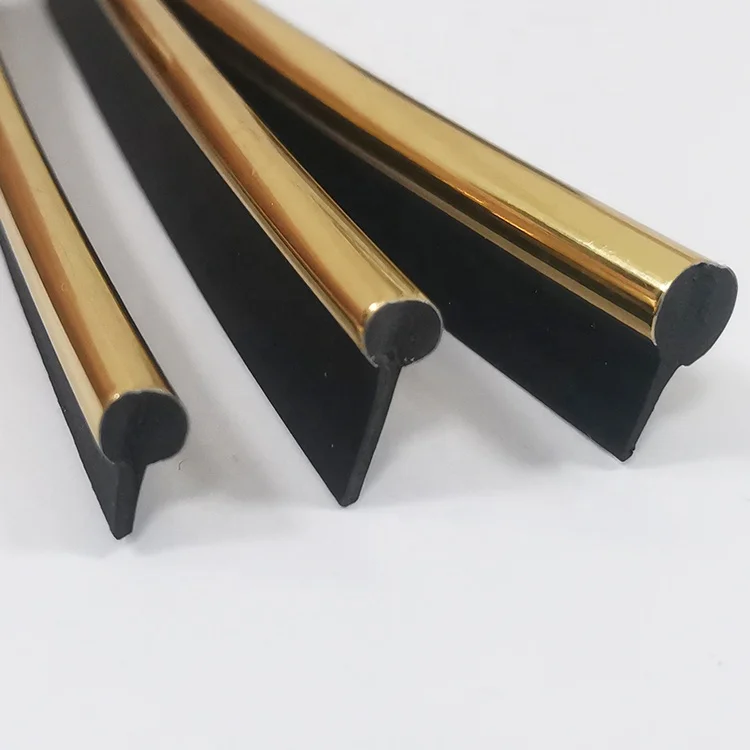

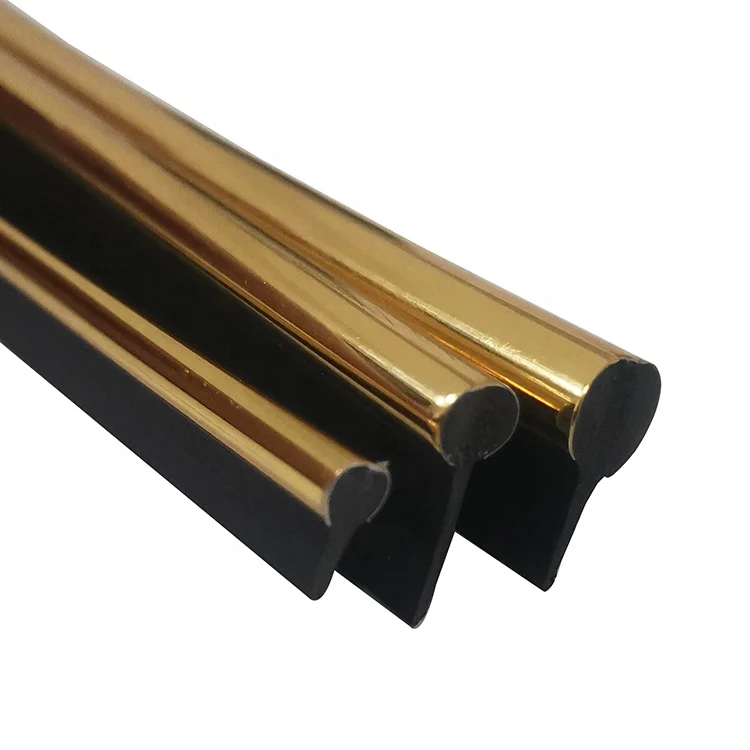

Window seal strip adhesive products are pressure-sensitive or hot-melt–backed extruded profiles, typically made from TPE, EPDM, or flexible PVC, engineered to deliver airtight, watertight, and sound-dampening barriers around window and door assemblies. In the plastic product industry and the Manufacturing of plastic profiles and strips, these profiles are co-extruded or laminated with adhesive tapes to streamline installation, improve assembly efficiency, and enhance long-term sealing performance. Leading window seal strip adhesive companies specify key parameters such as Shore A hardness tailored to compression needs, compression set resistance for longevity, UV/ozone stability for exterior use, and adhesive peel/tack suitable for substrates like anodized aluminum, coated steel, PVC frames, and glass.

Hebei Pulongte Rubber And Plastic Technology Co., Ltd. is a dependable window seal strip adhesive manufacturer with strong extrusion and adhesive-lamination capabilities for custom profiles, corners, and coiled supply. As a window seal strip adhesive company serving B2B buyers worldwide, Pulongte supports OEMs and fabricators with rapid sampling, stable lead times, and consistent quality control across batches. Whether you source from window seal strip adhesive factories domestically or work with a window seal strip adhesive exporter for global programs, Pulongte aligns with your specifications, packaging standards, and integration needs on modern fabrication lines.

Benefits & Use Cases of Window Seal Strip Adhesive Companies in Manufacturing of plastic profiles and strips

In plastic profile manufacturing, adhesive-backed window seal strips simplify assembly for aluminum windows, PVC windows, curtain walls, façade systems, modular buildings, caravans/RVs, HVAC access panels, and industrial cabinets. The pre-applied adhesive eliminates secondary gluing, reduces cure times, and supports automated application with consistent placement and bond strength. For B2B decision makers, this translates into faster takt times, fewer rework events, and standardized quality across production shifts.

- High-performance sealing: optimized compression load deflection, durable weather/UV resistance, and reliable acoustic/thermal insulation.

- Adhesive options: acrylic PSA for temperature stability and aging performance; hot-melt for fast initial tack; foam tapes for textured substrates.

- Customization: co-extrusion for multi-durometer designs, color matching, surface finishes, kiss-cut lengths, and private-label packaging.

- Supply advantages: as window seal strip adhesive suppliers and exporters, Pulongte supports flexible MOQs, consolidated shipments, and documentation for cross-border projects.

With extensive know-how in polymer selection and tooling, Hebei Pulongte Rubber And Plastic Technology Co., Ltd. helps specifiers select the right geometry and adhesive system for different frame materials. Whether you require standard window seal strip adhesive products or custom-engineered parts, Pulongte operates as a window seal strip adhesive factory capable of iterative prototyping, performance testing, and on-time delivery across multi-plant rollouts.

Cost, Maintenance & User Experience

The total cost of ownership for adhesive-backed seal strips is driven by installation speed, line yield, and lifetime sealing performance. By removing liquid adhesive steps and curing variability, fabricators can reduce labor hours and scrap rates, directly improving ROI. Durable substrates and adhesives also minimize field service calls, preserving margins for OEMs and installers. Window seal strip adhesive quotes typically reflect formulation choice, adhesive type, profile complexity, and packing method; consolidating SKUs and standardizing dimensions across models can unlock additional savings.

- Maintenance best practices: ensure clean, dry, dust-free surfaces (IPA wipe recommended), apply with steady pressure, and store rolls at moderate temperature/humidity.

- User experience: production teams value consistent unwind, controlled tack for repositioning windows, and stable adhesion after full cure. Procurement teams appreciate predictable lead times from reliable window seal strip adhesive suppliers.

- Lifecycle: robust compression set resistance and UV stabilization support long service life under outdoor exposure and repeated opening/closing cycles.

Hebei Pulongte Rubber And Plastic Technology Co., Ltd. provides technical guidance for surface prep, application pressure, and storage, helping customers in the plastic profiles sector achieve consistent adhesion and minimize rework. For multi-site manufacturers, Pulongte—acting as a window seal strip adhesive exporter—coordinates documentation and logistics to maintain continuity of supply and cost control.

Sustainability & Market Trends in manufacturing

Energy-efficient building envelopes and stricter air-leakage standards are accelerating demand for high-quality sealing profiles. At the same time, sustainability priorities—such as reduced VOCs, recyclability, and responsible material sourcing—are reshaping specifications. Window seal strip adhesive companies increasingly offer low-VOC adhesives, recyclable thermoplastic elastomers, and optimized packaging to reduce waste. In parallel, market trends like mass customization, short runs, and just-in-time delivery favor agile window seal strip adhesive factories able to switch tooling quickly and manage small-lot color matching.

- Material options: TPE and flexible PVC formulations can be tailored for recyclability and compliance with common environmental standards.

- Process efficiency: reduced secondary adhesives and faster assembly minimize energy consumption and waste on the production floor.

- Forward-looking supply: Hebei Pulongte Rubber And Plastic Technology Co., Ltd. adopts lean manufacturing practices, continuous improvement, and collaborative engineering to support eco-conscious specifications across regional and export markets.

As a window seal strip adhesive manufacturer and one of the dependable window seal strip adhesive exporters, Pulongte partners with OEMs to align material choices with sustainability targets while delivering the consistency global programs require.

Conclusion on Window Seal Strip Adhesive Companies from Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

For B2B teams in the plastic product industry, adhesive-backed sealing profiles offer measurable gains in assembly efficiency, product reliability, and lifecycle performance. Window seal strip adhesive companies that combine extrusion expertise with dependable adhesives create value across window, door, and façade applications. Hebei Pulongte Rubber And Plastic Technology Co., Ltd.—operating as a manufacturer, supplier, and exporter—delivers customized window seal strip adhesive products with consistent quality and responsive service. To request window seal strip adhesive quotes or discuss your next project, contact us at 85733247@qq.com or visit https://www.pulongte.com.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025