Window Seal Strip Adhesive Companies: Quality & Weatherproof Solutions

Sep . 09, 2025 20:40 Back to list

Window Seal Strip Adhesive Companies: Quality & Weatherproof Solutions

The Pivotal Role of Window Seal Strip Adhesive Companies in Modern Construction and Industry

In an era demanding enhanced energy efficiency, superior acoustic comfort, and robust environmental protection, the role of high-performance sealing solutions cannot be overstated. Among these, window seal strips, particularly those integrated with advanced adhesive technologies, stand as critical components. Navigating the complex market of suppliers, understanding the technical nuances, and selecting the right partner is paramount for any B2B decision-maker. This comprehensive guide explores the capabilities and offerings of window seal strip adhesive companies, detailing their manufacturing excellence, application expertise, and commitment to quality.

Whether you are seeking a reliable window seal strip adhesive manufacturer, a flexible window seal strip adhesive exporter, or require tailored solutions from expert window seal strip adhesive suppliers, understanding the landscape of these specialized entities is key. From material science to sophisticated production techniques, these firms deliver products essential for building integrity, operational efficiency, and occupant comfort across diverse sectors.

Industry Trends and Market Dynamics Driving Demand

The market for window seal strip adhesive products is experiencing robust growth, propelled by several key industry trends. Stringent building codes and increased consumer awareness regarding energy conservation are driving demand for seals with superior thermal insulation properties. Innovations in material science, such as advanced EPDM, silicone, and thermoplastic elastomer (TPE) compounds, coupled with high-performance acrylic or rubber-based adhesives, offer extended durability and environmental resistance.

Key Market Drivers:

- Energy Efficiency Mandates: Global push for reduced carbon footprints and lower heating/cooling costs.

- Sustainability: Preference for recyclable materials and manufacturing processes with minimal environmental impact.

- Enhanced Comfort: Demand for improved acoustic insulation and draft prevention in residential and commercial spaces.

- Smart Building Integration: Compatibility with advanced window systems and automated ventilation.

- Durability and Longevity: Need for seals that withstand harsh weather conditions, UV radiation, and temperature extremes for decades.

These factors compel window seal strip adhesive factories to continuously innovate, developing products that not only meet but exceed performance expectations, ensuring their competitiveness in a dynamic market.

Manufacturing Process Flow for Window Seal Strip Adhesive Products

The production of high-quality window seal strip adhesive products is a meticulous process, demanding precision and adherence to strict quality controls. Leading window seal strip adhesive companies employ advanced manufacturing techniques to ensure product consistency and performance.

Detailed Process Steps:

- Material Selection & Compounding: Raw materials such as EPDM rubber, silicone, PVC, or TPE granules are selected based on desired properties (flexibility, temperature resistance, chemical inertness). These are mixed with additives (UV stabilizers, colorants, vulcanizing agents) in precision mixers to create a homogeneous compound.

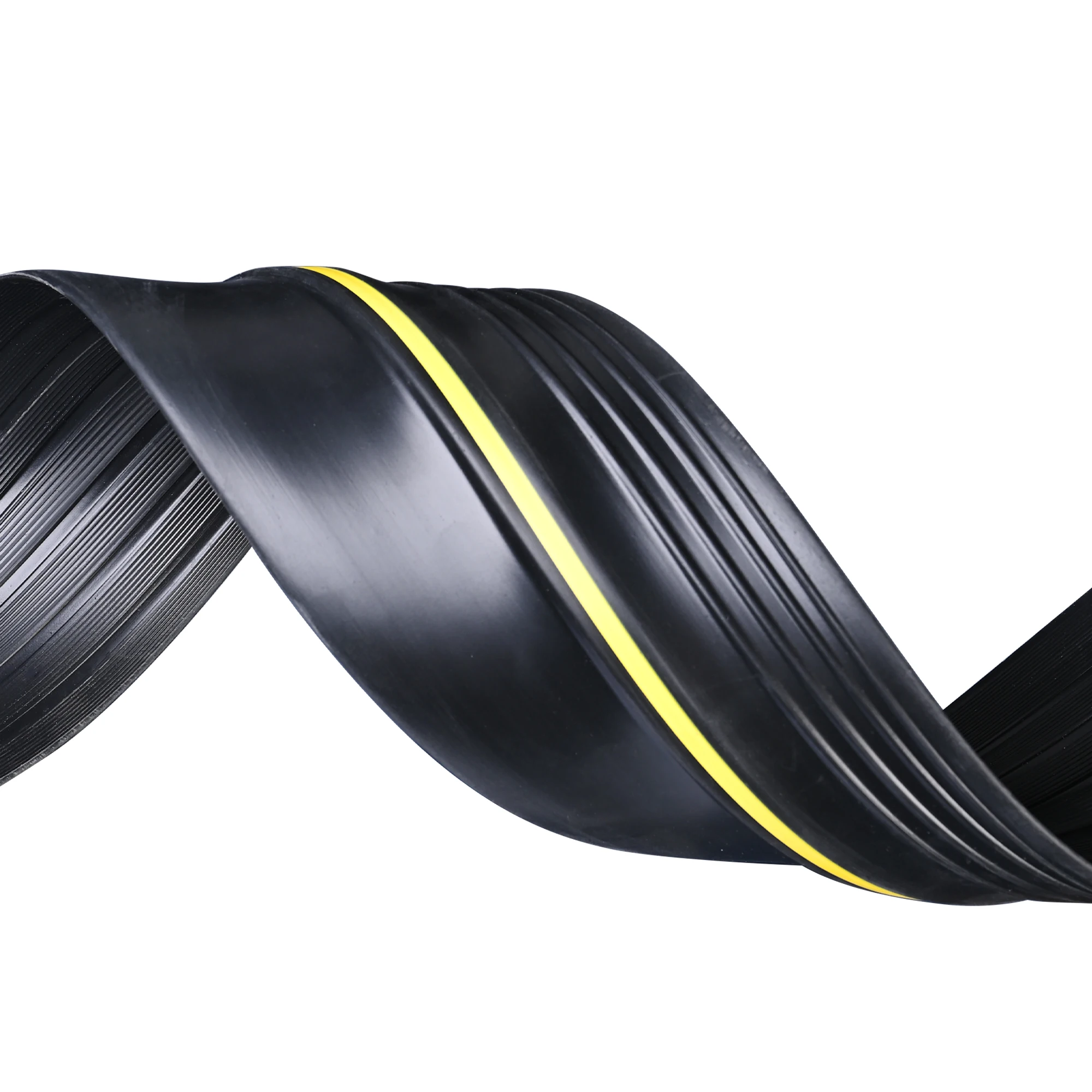

- Extrusion/Molding: The compounded material is then fed into an extruder, where it is heated and forced through a die to create the desired profile (e.g., D-profile, P-profile, bulb, flap). For more complex geometries, compression or injection molding may be utilized.

- Vulcanization/Curing: For rubber materials like EPDM, the extruded profile undergoes vulcanization in hot air ovens or salt baths. This chemical process strengthens the material, enhancing its elasticity, durability, and temperature resistance. PVC and TPE products typically cool and solidify upon exiting the die.

- Adhesive Application: A critical step involves applying high-performance pressure-sensitive adhesive (PSA) to one or more surfaces of the seal strip. This can be done via transfer tape lamination, direct coating, or co-extrusion for integrated adhesive layers. The adhesive choice (acrylic, silicone, rubber-based) depends on substrate compatibility, temperature range, and shear strength requirements.

- Cutting & Finishing: The continuous strip is then cut to specified lengths, either automatically or manually. Post-processing may include deburring, punching holes, or applying release liners to the adhesive side.

- Quality Control & Testing: Throughout the process, strict quality checks are performed. This includes dimensional verification, hardness testing (Shore A), tensile strength, elongation, tear resistance, compression set, and adhesive peel/shear strength. Weathering tests (UV exposure, ozone resistance) are also crucial. Compliance with international standards such as ISO 9001, ASTM, and DIN ensures product reliability.

- Packaging: Finished seals are carefully packaged, often on spools or in coils, to protect them during transit and storage.

Target Industries & Advantages:

These products find extensive use in the Building & Construction sector (residential, commercial, industrial windows), Automotive industry (car door and window seals), HVAC systems, and even specialized Marine and Appliance Manufacturing. The key advantages include significant energy saving through improved thermal envelopes, superior corrosion resistance due to moisture exclusion, noise reduction, and enhanced indoor air quality by preventing dust and pollutant ingress.

Technical Specifications and Product Parameters

Understanding the technical specifications of window seal strip adhesive products is vital for selecting the appropriate solution for specific applications. Parameters like material composition, adhesive type, hardness, temperature resistance, and compression set directly impact performance.

Material Property Comparison:

| Property | EPDM Rubber | Silicone Rubber | PVC (Flexible) | TPE (Thermoplastic Elastomer) |

|---|---|---|---|---|

| Temperature Range | -40°C to 120°C | -60°C to 230°C | -20°C to 60°C | -30°C to 100°C |

| UV Resistance | Excellent | Excellent | Good (can harden over time) | Very Good |

| Ozone Resistance | Excellent | Excellent | Fair to Good | Good |

| Flexibility | Excellent | Excellent | Good | Excellent |

| Compression Set | Good | Excellent | Fair | Good |

Generic Product Specification Example (Window Seal Strip):

While the provided product URL references a garage door seal, the principles apply similarly to window seals. Here's a generalized specification table for typical window seal strip adhesive products.

| Parameter | Specification Range | Test Standard |

|---|---|---|

| Material Type | EPDM, Silicone, PVC, TPE | ASTM D2000, ISO 1629 |

| Hardness (Shore A) | 30 – 80 | ASTM D2240 |

| Tensile Strength | 5 – 15 MPa | ASTM D412 |

| Elongation at Break | 150% – 500% | ASTM D412 |

| Adhesive Type | Acrylic, Rubber-based, Silicone | Proprietary/Industry Standard |

| Adhesive Peel Strength (180°) | ≥ 10 N/25mm (on steel) | ASTM D3330 |

| Service Life | 10 – 20+ Years | Accelerated Weathering |

Application Scenarios and Case Studies

The versatility of modern window seal strip adhesive solutions allows for their application across a myriad of environments, each benefiting from their distinct properties.

Typical Application Scenarios:

- Residential Buildings: Used in window frames (e.g., casement, sliding, double-hung) to prevent drafts, reduce heat loss, block dust, and improve sound insulation. This enhances occupant comfort and significantly cuts heating/cooling costs.

- Commercial Properties: Applied in large-scale office buildings, retail spaces, and hotels to maintain consistent indoor temperatures, reduce external noise intrusion, and meet stringent energy efficiency certifications like LEED.

- Industrial Facilities: In manufacturing plants or processing facilities, seals protect sensitive equipment from dust, moisture, and chemical vapors, or help maintain controlled environments like cleanrooms.

- Healthcare & Education: Essential for maintaining sterile environments in hospitals and quiet learning spaces in schools, minimizing noise and preventing the spread of airborne particles.

- Automotive: While primarily focused on windows, similar seal technologies are critical for automotive window and door seals, providing weatherproofing, noise damping, and vibration reduction.

Application Case Study: High-Rise Commercial Building Retrofit

A prominent commercial building in a major metropolitan area faced escalating energy costs and tenant complaints about drafts and external noise. An assessment revealed that aging window seals were the primary culprit, leading to significant thermal leakage and poor acoustic performance. A leading window seal strip adhesive company was consulted to provide a durable and effective solution.

The chosen solution involved high-performance EPDM seal strips with a specialized acrylic adhesive, known for its strong bond to aluminum window frames and long-term weather resistance. The project involved replacing existing seals on over 1,500 windows. Post-installation, the building reported an average 18% reduction in HVAC energy consumption within the first year. Tenant satisfaction surveys showed a marked improvement in thermal comfort and a perceived 10-12 dB reduction in interior noise levels, validating the investment in quality window seal strip adhesive products.

Technical Advantages of Modern Window Seal Strips

Modern window seal strip adhesive solutions offer a host of technical advantages that contribute to their widespread adoption and superior performance compared to older alternatives.

Key Advantages:

- Superior Weather Resistance: Advanced materials like EPDM and silicone exhibit excellent resistance to UV radiation, ozone, extreme temperatures (-60°C to +230°C for silicone), and moisture, ensuring long-term performance without cracking or degrading.

- Enhanced Thermal & Acoustic Insulation: Optimized profiles and dense material compositions create effective barriers against heat transfer and sound waves, contributing to energy savings and improved indoor acoustics.

- Exceptional Durability & Service Life: Designed for longevity, these seals maintain their elastic properties and sealing integrity for 10-20 years or more, reducing the need for frequent replacement.

- High-Performance Adhesion: Specialized pressure-sensitive adhesives provide strong, immediate bonds to various substrates (aluminum, PVC, wood, glass) and maintain adhesion under dynamic stress and environmental fluctuations.

- Chemical Resistance: Many modern seals offer good resistance to common cleaning agents, mild acids, and alkalis, making them suitable for diverse environments.

- Ease of Installation: The self-adhesive backing simplifies installation, reducing labor time and costs for installers, particularly for large-scale projects.

- Aesthetics & Customization: Available in various colors and profiles, they can seamlessly integrate with window designs, and window seal strip adhesive companies offer customization for specific aesthetic or functional needs.

These advantages underscore why investing in quality window seal strip adhesive products from reputable suppliers is a strategic decision for any construction or industrial project.

Vendor Comparison and Selection Criteria

When seeking a partner among the many window seal strip adhesive companies, a systematic approach to vendor comparison is crucial. Factors such as material quality, manufacturing capabilities, certifications, and support services differentiate a reliable supplier from others.

Key Selection Criteria:

- Material Expertise: Does the window seal strip adhesive manufacturer offer a wide range of materials (EPDM, silicone, TPE, PVC) and can they advise on the best fit for your application?

- Manufacturing Capabilities: Assess their production capacity, process control, and ability to handle both standard and custom profiles. What are their testing standards (e.g., ISO, ASTM)?

- Adhesive Technology: Inquire about the types of adhesives used, their bonding strength, temperature resistance, and compatibility with various substrates.

- Quality Certifications: Look for certifications like ISO 9001 for quality management, RoHS/REACH compliance for environmental safety, and specific product performance certifications.

- Customization Options: Can they provide bespoke solutions for unique window designs or specific performance requirements?

- Lead Time & Logistics: Evaluate their typical lead times for orders, minimum order quantities (MOQs), and logistical capabilities, especially if you need a window seal strip adhesive exporter.

- Technical Support & Customer Service: A strong vendor provides expert technical assistance, prompt communication, and responsive after-sales support.

- Pricing & Value: While cost is a factor, focus on the overall value proposition, considering product longevity, performance, and warranty, rather than just upfront price. Obtain competitive window seal strip adhesive quotes but compare comprehensively.

Product Comparison: Standard vs. Premium Adhesive Seals

| Feature | Standard PVC/Rubber Seal | Premium EPDM/Silicone Seal |

|---|---|---|

| Material Base | PVC, SBR Rubber | EPDM, Silicone, High-Grade TPE |

| Adhesive Type | Standard Rubber-based PSA | High-Performance Acrylic/Silicone PSA |

| UV/Ozone Resistance | Moderate (can degrade) | Excellent (long-lasting stability) |

| Temperature Range | Limited (-20°C to 80°C) | Wide (-60°C to 230°C for Silicone) |

| Service Life | 5-10 Years | 15-25+ Years |

| Adhesion Strength | Good Initial, moderate long-term | Excellent, stable over time and temperature |

Customized Solutions from Leading Companies

Many discerning clients require more than off-the-shelf window seal strip adhesive products. This is where the expertise of a specialized window seal strip adhesive company truly shines, offering bespoke solutions tailored to unique project demands.

Customization Capabilities Include:

- Profile Design: Engineering custom cross-sections to perfectly match specific window frame geometries or sealing gaps, optimizing compression and sealing efficiency.

- Material Formulation: Developing unique polymer blends to achieve specific properties, such as enhanced chemical resistance, fire retardancy, or ultra-low compression set.

- Adhesive Tailoring: Customizing adhesive types, thickness, or pattern for optimal adhesion to challenging substrates or for extreme environmental conditions (e.g., high humidity, extreme temperatures).

- Color Matching: Producing seals in specific colors to blend seamlessly with architectural designs or branding requirements.

- Prototyping & Testing: Offering rapid prototyping services and comprehensive testing of custom solutions to validate performance before mass production.

Engaging with a window seal strip adhesive factory that possesses strong R&D capabilities and a collaborative engineering team ensures that even the most complex sealing challenges can be met with innovative and effective solutions.

Ensuring Authoritativeness and Trustworthiness ()

In the B2B sector, trust and verifiable credentials are non-negotiable. Reputable window seal strip adhesive companies build their reputation on a foundation of expertise, experience, authority, and trustworthiness.

Authoritative Indicators:

- Industry Certifications: Adherence to ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and specific product certifications like ASTM standards, DIN norms, or even UL listings where applicable.

- Partner Clients & Years of Service: Long-standing relationships with tier-one construction firms, window manufacturers, and industrial clients are strong indicators of reliability. A track record of decades in the industry further solidifies their standing.

- Test Data & Reporting: Providing comprehensive test reports for mechanical properties, weatherability, and adhesion performance, often conducted by independent third-party laboratories.

- Research & Development: Investment in R&D to develop new materials, profiles, and adhesive technologies demonstrates a commitment to innovation and maintaining a competitive edge.

Trustworthiness Measures:

- FAQ Module: Transparently addressing common queries demonstrates a commitment to customer education and support.

- Lead Time & Fulfillment: Clear communication regarding manufacturing lead times and reliable order fulfillment processes.

- Warranty Commitments: Offering robust product warranties that cover material and manufacturing defects instills confidence in product quality.

- Customer Support: Accessible and knowledgeable customer service, including technical support for installation or application queries.

Frequently Asked Questions (FAQ)

Q1: How do I choose the correct window seal strip for my application?

A: The selection depends on several factors: the type of window (e.g., casement, sliding), the size and shape of the gap to be sealed, environmental conditions (temperature extremes, UV exposure), desired performance (thermal, acoustic, water resistance), and the substrate material (wood, PVC, aluminum). Consult with experienced window seal strip adhesive suppliers who can recommend the optimal material (EPDM, silicone, TPE, PVC) and profile.

Q2: What is the typical service life of modern window seal strips?

A: High-quality EPDM and silicone seal strips with robust adhesives are designed for exceptional longevity. Under normal operating conditions, they can maintain their sealing effectiveness for 15-25 years or even longer. Factors like extreme UV exposure, harsh chemicals, or continuous mechanical abrasion can influence lifespan, which is why choosing durable window seal strip adhesive products is essential.

Q3: Are customized window seal strip solutions expensive?

A: While custom tooling and unique material formulations may incur initial development costs, the long-term benefits often outweigh this. Tailored solutions ensure a perfect fit, optimized performance, and extended durability, leading to significant savings in energy, maintenance, and replacement costs over the product's lifespan. Many window seal strip adhesive companies offer cost-effective customization for medium to large-volume orders.

Q4: What makes the adhesive component so important for window seals?

A: The adhesive is critical for secure, long-lasting installation. A high-quality adhesive ensures that the seal strip remains firmly in place, even under temperature fluctuations, window movement, and environmental stresses. It prevents detachment, which would compromise the seal's effectiveness and lead to drafts, leaks, or noise infiltration. Reputable window seal strip adhesive manufacturers invest heavily in adhesive R&D to ensure superior bond strength and longevity.

Logistics, Warranty, and Customer Support

Beyond product quality, the operational excellence of window seal strip adhesive companies is demonstrated through their commitment to logistics, warranties, and after-sales support.

Lead Time & Fulfillment:

Standard products typically have lead times ranging from 2-4 weeks, depending on inventory levels and order volume. Custom orders, due to tooling and specialized production, may require 6-10 weeks. Efficient window seal strip adhesive exporters leverage global logistics networks to ensure timely and cost-effective delivery, minimizing project delays for international clients.

Warranty Commitments:

Most reputable manufacturers offer warranties against material and manufacturing defects, typically ranging from 1 to 5 years. For premium products, extended warranties of up to 10 years may be available, reflecting confidence in the product's durability and performance. Always review specific warranty terms for the window seal strip adhesive products you are purchasing.

Customer Support & Technical Assistance:

Leading companies provide comprehensive customer support, including technical consultations, product data sheets, installation guides, and troubleshooting assistance. Dedicated account managers and technical engineers are often available to assist B2B clients with product selection, application challenges, and custom solution development, ensuring optimal outcomes for every project.

Conclusion

The success of modern construction and industrial projects hinges significantly on the quality of their sealing solutions. The specialized expertise of window seal strip adhesive companies is indispensable, offering innovative products that address critical needs for energy efficiency, comfort, and structural integrity. By prioritizing material science, precision manufacturing, and comprehensive customer support, these firms provide the foundational components for high-performing, sustainable buildings and efficient industrial operations.

Choosing the right partner among the various window seal strip adhesive factories or window seal strip adhesive suppliers involves a thorough evaluation of their technical capabilities, quality assurances, and ability to deliver tailored solutions. Investing in high-quality seal strip adhesive products is not merely a purchase; it's a strategic decision that pays dividends in long-term performance, reduced operational costs, and enhanced environmental responsibility.

References

- American Society for Testing and Materials (ASTM) International. "Standard Test Methods for Rubber Property—Tension." ASTM D412.

- International Organization for Standardization (ISO). "Rubber and plastics — Generic types of materials — EPDM." ISO 1629.

- Environmental Protection Agency (EPA). "Energy Efficiency and Renewable Energy." www.energy.gov.

- Adhesion Society. "Advances in Adhesive Technology." Journal of Adhesion.

- ASHRAE Journal. "Building Enclosure Air Leakage: Impact on Energy Consumption."

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025