Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision Manufacturing, Acrylic Shaping

Oct . 06, 2025 05:35 Back to list

Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision Manufacturing, Acrylic Shaping

Introduction

The Acrylic Heat Bender Tool-Type A represents a significant advancement in precision manufacturing, offering a versatile solution for shaping acrylic materials with exceptional accuracy. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., this tool is designed to meet the demands of both industrial and DIY applications. This article explores the features, advantages, technical specifications, and real-world applications of the Acrylic Heat Bender Tool-Type A, while highlighting the company's commitment to innovation and quality.

Product Features

The Acrylic Heat Bender Tool-Type A is engineered to deliver precision manufacturing and efficiency. Key features include:

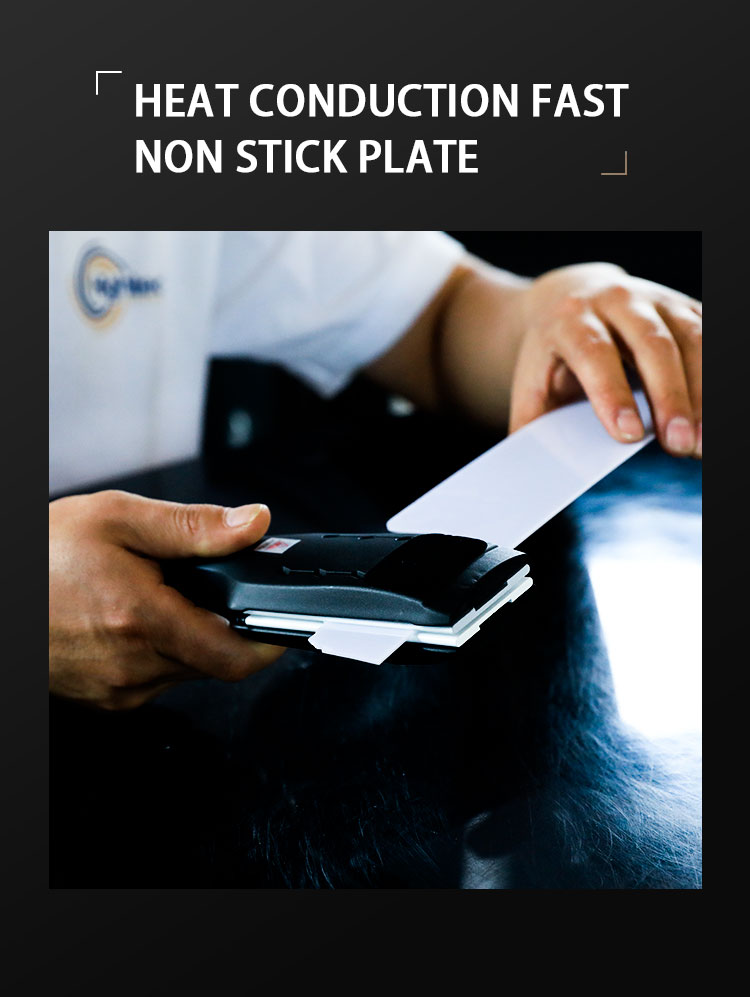

- Advanced Heating Technology: The tool utilizes a high-precision heating system to ensure uniform temperature distribution, allowing for consistent and accurate shaping of acrylic materials.

- Durable Construction: Built with high-quality materials, the tool is designed to withstand prolonged use in demanding industrial environments.

- User-Friendly Design: The ergonomic handle and intuitive controls make it easy to operate, even for users with limited experience in acrylic shaping.

- Adjustable Temperature Settings: Users can customize the heating temperature to suit different types of acrylic, enhancing versatility and reducing the risk of material damage.

- Compact and Portable: Despite its robust build, the tool is lightweight and easy to transport, making it suitable for both workshop and on-site applications.

Key Advantages

The Acrylic Heat Bender Tool-Type A offers several advantages that make it a preferred choice for manufacturers and hobbyists alike:

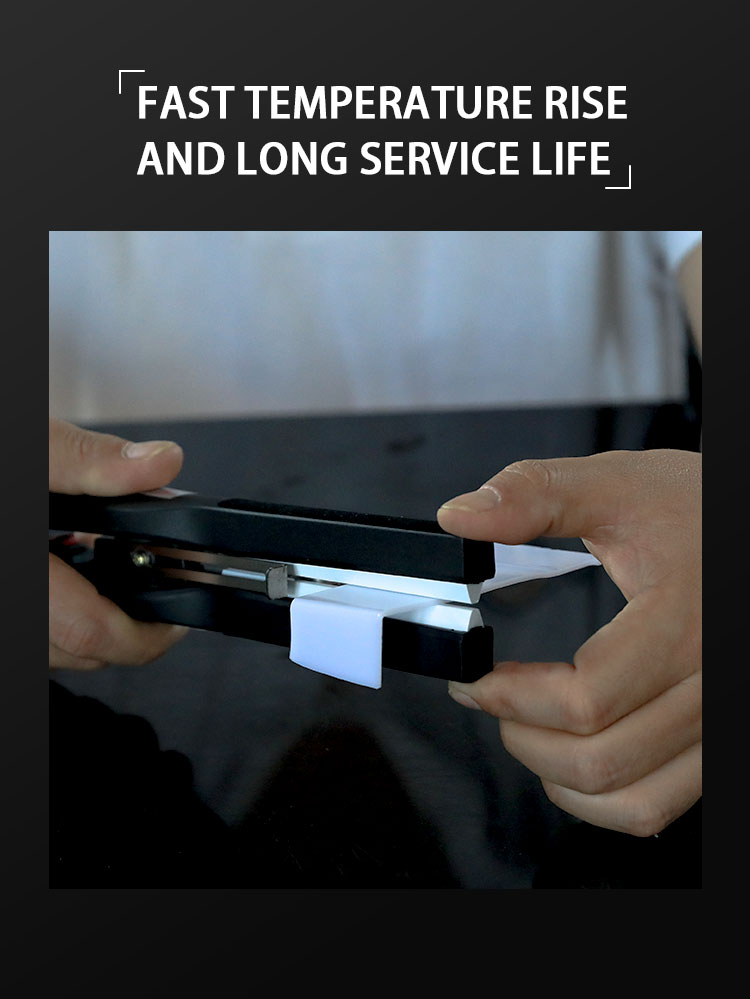

- Enhanced Efficiency: The tool's rapid heating capabilities significantly reduce the time required to shape acrylic, improving overall productivity.

- Cost-Effectiveness: By minimizing material waste and reducing the need for rework, the tool helps lower production costs.

- High-Quality Results: The precise temperature control and uniform heating ensure that acrylic pieces are shaped with minimal distortion, resulting in professional-grade finishes.

- Wide Range of Applications: From custom lighting fixtures to intricate 3D acrylic structures, the tool can handle a variety of projects, making it a valuable asset in diverse industries.

- Easy Maintenance: The tool's design allows for straightforward cleaning and maintenance, ensuring long-term reliability and performance.

Technical Specifications

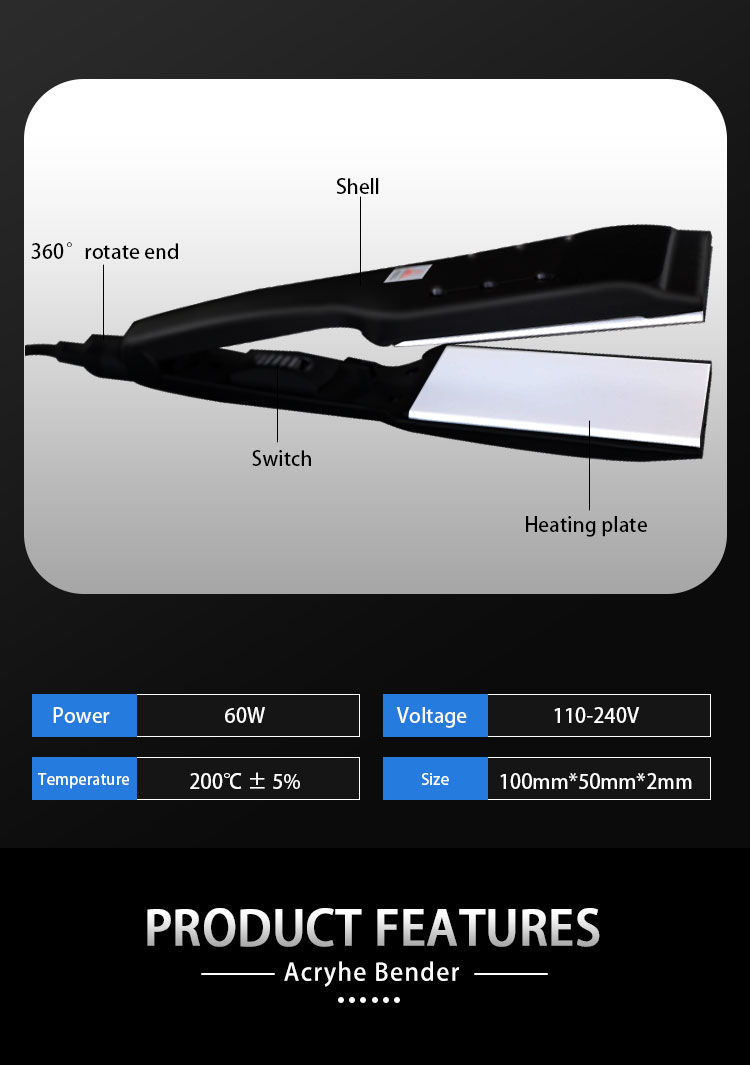

| Specification | Details |

|---|---|

| Heating Element | High-efficiency ceramic heating coil |

| Temperature Range | 100°C to 200°C (212°F to 392°F) |

| Power Supply | 120V AC, 60Hz |

| Dimensions | 18.5 x 10 x 5 inches |

| Weight | 4.2 lbs |

| Material | Aluminum alloy and heat-resistant plastic |

| Control System | Digital temperature display with adjustable settings |

Application Scenarios

The Acrylic Heat Bender Tool-Type A is suitable for a wide range of applications, including:

- Custom Lighting Fixtures: The tool is ideal for creating intricate lampshades and light covers, as demonstrated in the Light Cover Acrylic Lampshade image.

- Architectural Accents: It can be used to fabricate 3D acrylic trim caps, such as the 3D Metal Acrylic Trim Cap, which adds a modern touch to interior and exterior designs.

- Industrial Components: The tool's precision makes it suitable for manufacturing custom parts in industries like automotive and aerospace.

- DIY Projects: Hobbyists can use the tool to create personalized acrylic items, from signage to decorative pieces.

- Prototyping: The tool's versatility allows for rapid prototyping of acrylic-based products, accelerating the development process.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Founded in 2010, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. is a leading manufacturer and supplier of acrylic and plastic products based in Hebei, China. With over a decade of experience, the company has established itself as a trusted name in the industry, known for its commitment to quality, innovation, and customer satisfaction.

Hebei Pulongte specializes in the production of high-quality acrylic tools and accessories, including the Acrylic Heat Bender Tool-Type A. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every product meets international standards. Hebei Pulongte serves a global clientele, exporting its products to various countries and regions, as highlighted in the Acrylic Heat Bender Tool-Type A Exporter image.

Industry Relevance and NIST Standards

The development of tools like the Acrylic Heat Bender Tool-Type A aligns with the broader goals of advancing precision manufacturing, as emphasized by the National Institute of Standards and Technology (NIST). According to NIST, "Precision manufacturing is critical for ensuring the reliability and performance of products across industries, from aerospace to consumer goods" (NIST, 2023). The Acrylic Heat Bender Tool-Type A exemplifies this principle by providing a reliable solution for shaping acrylic materials with minimal errors.

NIST's research on manufacturing standards underscores the importance of tools that enhance efficiency and reduce waste. By incorporating advanced heating technology and precise temperature control, the Acrylic Heat Bender Tool-Type A contributes to these objectives, as noted in NIST's report on "Innovative Manufacturing Solutions" (2022).

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to Hebei Pulongte Rubber and Plastic Technology Co., Ltd.'s dedication to innovation and quality. With its advanced features, user-friendly design, and wide range of applications, this tool is an indispensable asset for manufacturers and hobbyists alike. As highlighted by NIST's research, the integration of precision tools like this one is essential for driving progress in the manufacturing sector. Whether you're creating custom lighting fixtures, architectural accents, or industrial components, the Acrylic Heat Bender Tool-Type A delivers the performance and reliability needed to achieve exceptional results.

References

National Institute of Standards and Technology (NIST). (2023). Precision Manufacturing: Ensuring Reliability and Performance. Retrieved from https://www.nist.gov.

National Institute of Standards and Technology (NIST). (2022). Innovative Manufacturing Solutions. Retrieved from https://www.nist.gov.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025