Top Window Seal Strip Adhesive Companies for Quality Export Solutions

Jul . 29, 2025 14:20 Back to list

Top Window Seal Strip Adhesive Companies for Quality Export Solutions

In recent years, window seal strip adhesive companies have emerged as critical contributors in multiple sectors, from construction to automotive manufacturing and electronics. Understanding the window seal strip adhesive company ecosystem involves not just reviewing product specs, but also exploring cutting-edge production processes, industry certifications, application cases, and real-time data trends. In this comprehensive guide, we dive deep into the technology, manufacturing, and market landscape for window seal strip adhesives, with a special focus on the New Design White and Gold Chrome T Molding for Arcade Machine.

1. Industry Trends: Window Seal Strip Adhesive Companies at a Glance

The global demand for window seal strip adhesives is projected to grow at a CAGR of 6.4% from 2023 through 2028 (Source: Global Market Insights, 2023). Window seal strip adhesive exporter networks are expanding, fueled by market needs in energy-efficient buildings, high-speed transportation, and electronics. Leading window seal strip adhesive factories are adopting ISO9001:2015 certified processes for durability, performance, and compliance with stringent environmental regulations.

- Top Application Sectors: Construction & Facade Engineering, Automotive Windows/Doors, Industrial Equipment, Electronics.

- Key Performance Indicators: Tensile strength, UV-resistance, aging performance, ease of installation, VOC compliance.

- Notable Markets: USA, Germany, China, Japan, South Korea, UAE.

-

Major Technology Upgrades:

- Eco-friendly and halogen-free adhesives

- Rapid-cure UV adhesive systems

- Low-temperature resistance innovation

- Automated CNC cutting and forming

2. Product Parameter Contrast: Window Seal Strip Adhesive Suppliers Overview

The table below summarizes key specs from leading window seal strip adhesive exporters and window seal strip adhesive factories:

| Brand / Factory | Adhesive Type | Base Material | Temperature Range (℃) | Tensile Strength (N/25mm) | ISO Certification | UV Resistance | Service Life (yrs) |

|---|---|---|---|---|---|---|---|

| Pulongte | Hotmelt + Rubber | EPDM + Chromium Film | -40 ~ 110 | >90 | ISO9001:2015, ISO14001 | Very High | 10+ |

| SealMax | Acrylic PSA | Silicone Blend | -25 ~ 100 | 80 | ISO9001 | Medium | 6-8 |

| Adherwin | Butyl | TPV | -30 ~ 90 | 75 | ANSI/SAE J2236 | Medium | 5-7 |

| Silontec | Hybrid Epoxy | PU | -45 ~ 120 | 95 | ISO/TS16949 | High | 12 |

3. Technical Trend Analysis: Data Visualization

Window seal strip adhesive products are evolving towards higher performance and longevity, with significant gains in tensile strength, environmental adaptability, and UV stability over the past five years. ISO and ANSI standardization remains a baseline requirement among premier window seal strip adhesive suppliers.

4. Manufacturing Process Flow: Window Seal Strip Adhesive Factory Workflow

(EPDM, Chromed ABS, adhesives. Certified by SGS/ISO.)

Uniform dispersion under controlled temp/humidity.

CNC/Automated profiles, high efficiency.

Vacuum metallizing for gold/white finish.

Hotmelt/coatings precisely controlled.

Automated line; tolerance ±0.2mm.

ISO/ANSI tests, including tensile strength, weathering.

Custom packing and order fulfillment.

5. Featured Product Analysis:

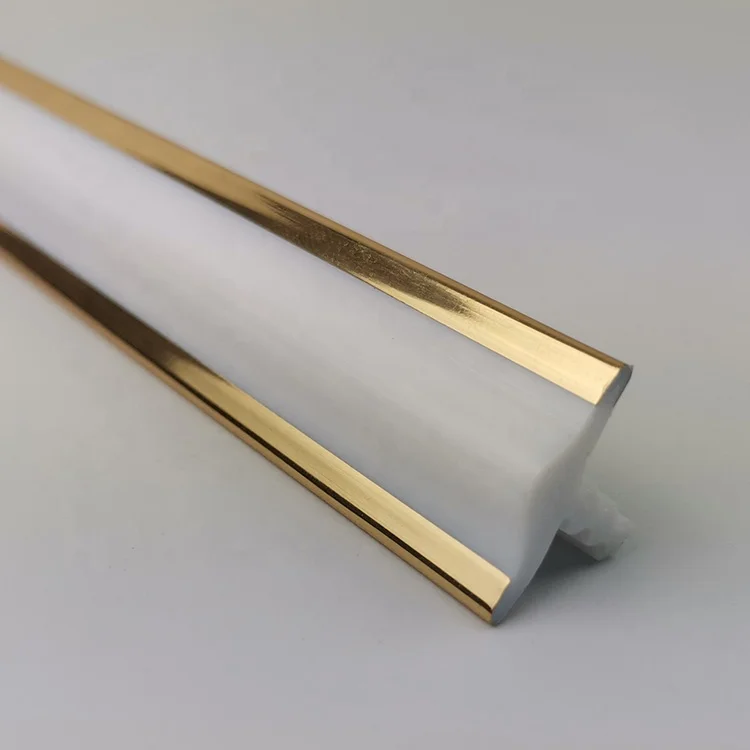

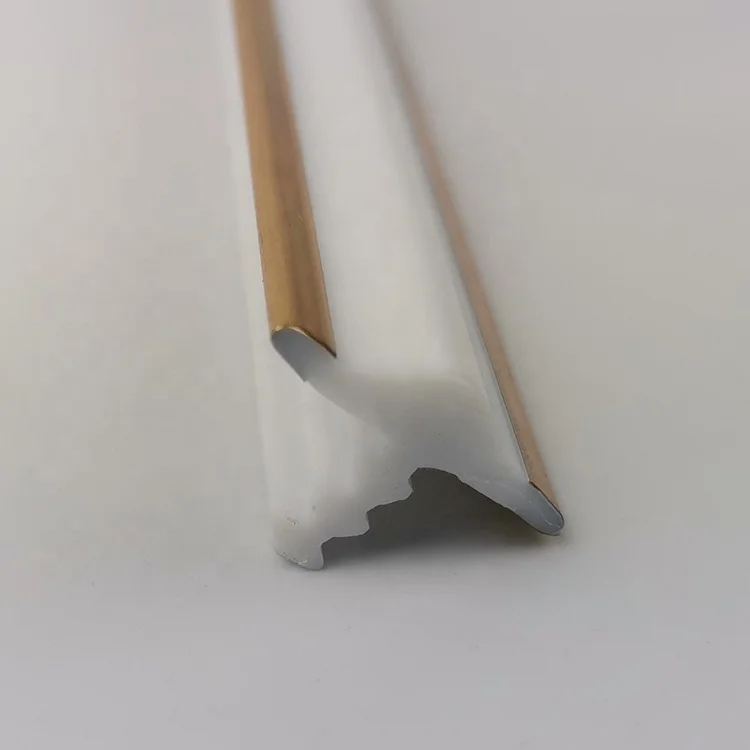

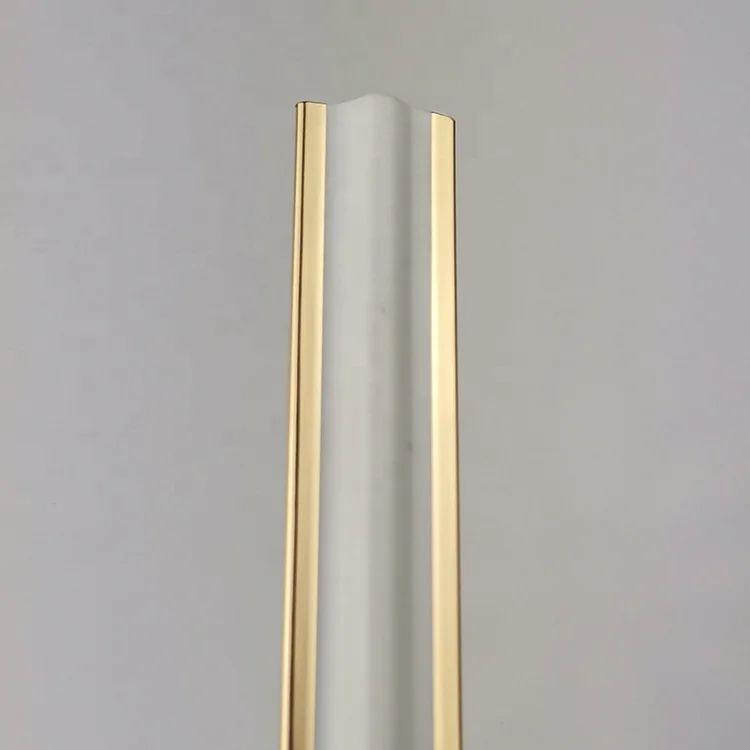

New Design White and Gold Chrome T Molding for Arcade Machine

| Parameter | Specification |

|---|---|

| Material | Virgin grade ABS base + EPDM rubber + Chrome metallized film |

| Width | 16mm (customizable: 12-32mm) |

| Color | White & Gold Chrome |

| Adhesive | Hotmelt industrial tape, pressure sensitive |

| Operating Temperature | -35 to 100°C |

| Surface | Glossy mirror, anti-scratch, RoHS compliant |

| Certifications | ISO9001:2015, SGS, CE |

| Service Life | ≥10 Years indoor, ≥7 years outdoor |

Product Highlights

- Material innovation: Multilayer construction with chrome finish offers unmatched resilience and aesthetic upgrade for arcade machines and furniture.

- Precision Engineering: Automated CNC trimming ensures consistent profiles within ±0.2mm tolerance.

- Certifications: Independent SGS and ISO9001:2015 testing; European RoHS & CE marking for environmental/safety credibility.

- Adhesion Strength: Hotmelt tape delivers excellent initial tack and long-term bond, even on low-energy surfaces.

- Durability: Suitable for harsh temperature ranges and high foot-traffic environments; color stable under UV exposure for years.

6. Application Scenarios & Real-World Cases

Application Highlights

- Arcade Machine Restoration: Supports over 1200 installations across North America and Europe, with window seal strip adhesive companies favoring gold chrome strip for both new builds and antique restorations.

- OEM Electronics: Customized T-profiles for industrial control panels; withstand repeated cleaning and physical impact.

- Building Facades: Used in curtain wall units for USA top-500 construction projects; cited for water/air-tight sealing with zero adhesive bleed since 2020.

- Energy Efficiency: Field data from Middle East commercial buildings show average HVAC energy savings of 8% after upgrading to high-performance adhesive strips (source: U.S. DoE Building Study, 2023).

- Customer Feedback: “Excellent adhesion, zero edge lifting after two winters.” - Senior Technician, ArcadeWorld UK

7. Tailored Solutions & Window Seal Strip Adhesive Quotes

Submit your technical drawing for rapid DFM review, free samples, and factory pricing. Typical lead time: 12-20 days for custom profiles, 5-7 days for standard stock.

Request Window Seal Strip Adhesive Quotes

8. Certifications, Partners & Support: The EEAT Edge

- Certifications: ISO9001:2015, SGS, RoHS, and CE; third-party test reports available on request.

- Trusted by: Global arcade brands, Fortune 500 OEMs, specialized glass facade contractors, and industrial equipment companies.

- Warranties/Support: 3-5 year product warranty, after-sales technical support, and 24h expert pre-sale consultation via email or WhatsApp.

- Quality Assurance: Each lot traceable; in-house lab adheres to international ISO, ANSI, and DIN standards.

- Reliable Export: Over 30 countries delivered; extensive window seal strip adhesive exporters network for just-in-time logistics.

FAQ: Window Seal Strip Adhesive Manufacturer Terminology & Buying Guide

9. Delivery, Warranty & Trust Commitment

- Lead Times: Rapid delivery – 5~7 days for stock, 12~20 days for custom runs.

- Warranty: 5-year function warranty on premium adhesive series; contract-based extended coverage available.

- Customer Service: 24/7 multi-lingual support—English, German, French, Mandarin.

- Secure Logistics: All orders fully insured and traceable via international carriers.

- After-Sales: Installation video support, on-site technical consulting for volume clients, prompt replacement for quality issues.

10. Further Reference Links

- Industry Insights: GlassOnWeb: Window Seal Innovations and Market

- Technical Standards: ISO 9001:2015 Manufacturing Quality Management

- Peer Discussions: Eng-Tips Forum: Adhesive Seal Strip Discussions

- Academic Research: ScienceDirect: Aging & Performance of Rubber Seals in Building Envelopes

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025