Manufacturers of plastic seal strips for shower doors

Jun . 17, 2024 16:44 Back to list

Manufacturers of plastic seal strips for shower doors

Exploring the World of Shower Door Plastic Seal Strip Factories

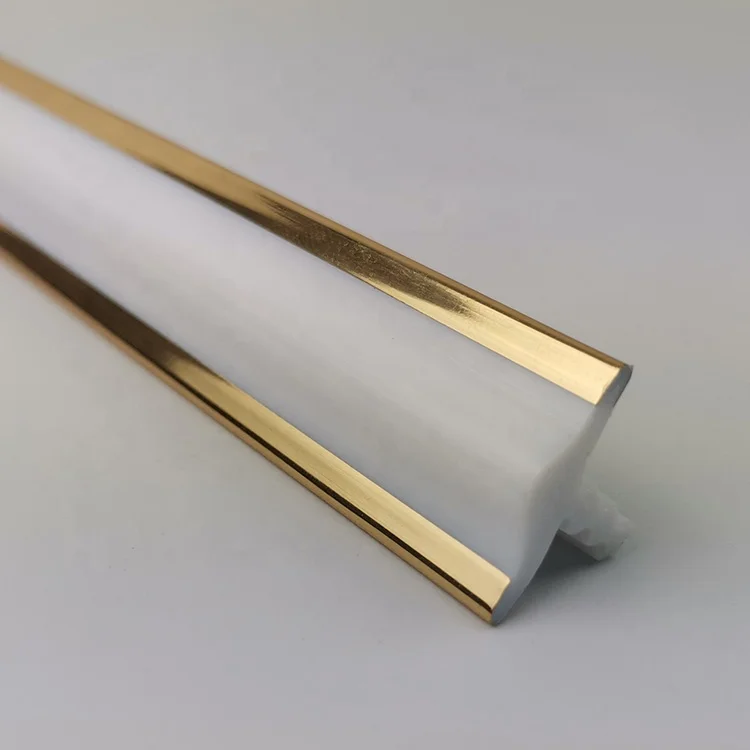

In the realm of bathroom fixtures and accessories, the shower door plastic seal strip holds a vital position. It is an essential component that safeguards the integrity of the shower area, preventing water leakage and ensuring a safe, comfortable, and efficient bathing experience. This article delves into the factories that specialize in manufacturing these indispensable seals.

Shower door plastic seal strip factories are scattered globally, with a significant concentration in countries known for their industrial prowess, such as China, Germany, and the United States. These facilities are equipped with cutting-edge technology and dedicated teams to produce high-quality strips tailored to various shower door designs and requirements.

The production process in these factories begins with the selection of raw materials. High-grade plastics, such as PVC, PE, or TPE, are commonly used due to their durability, flexibility, and resistance to water and humidity. The materials undergo rigorous quality checks to ensure they meet industry standards before entering the production line.

Once the materials are approved, they are fed into specialized machines that extrude the plastic into the desired strip shape. Precision engineering is crucial at this stage to guarantee the strips fit snugly on the shower doors, providing an effective barrier against water seepage. The strips are then cooled and hardened, ready for the next phase.

Quality control is a non-negotiable aspect in these factories. Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects

Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects shower door plastic seal strip factories. This ensures that only the best quality products reach the market.

Customization is a key feature offered by many shower door plastic seal strip factories. They cater to diverse customer needs, whether it's a standard size for a typical shower enclosure or a bespoke design for a unique architectural installation. Factories often collaborate closely with designers and architects to create seals that not only function optimally but also complement the aesthetic of the bathroom space.

Environmental sustainability is another focus area for many factories. They invest in eco-friendly practices, from using recyclable materials to minimizing waste during production. Some even develop seals made from biodegradable plastics, reflecting their commitment to reducing environmental impact.

In conclusion, shower door plastic seal strip factories play a crucial role in our daily lives, often unnoticed but always functional. Their dedication to precision engineering, quality control, customization, and sustainability ensures that we enjoy a comfortable showering experience while preserving the integrity of our bathrooms. As technology advances and consumer demands evolve, these factories continue to innovate, pushing the boundaries of functionality and aesthetics in the world of shower door seals.

shower door plastic seal strip factories. This ensures that only the best quality products reach the market.

Customization is a key feature offered by many shower door plastic seal strip factories. They cater to diverse customer needs, whether it's a standard size for a typical shower enclosure or a bespoke design for a unique architectural installation. Factories often collaborate closely with designers and architects to create seals that not only function optimally but also complement the aesthetic of the bathroom space.

Environmental sustainability is another focus area for many factories. They invest in eco-friendly practices, from using recyclable materials to minimizing waste during production. Some even develop seals made from biodegradable plastics, reflecting their commitment to reducing environmental impact.

In conclusion, shower door plastic seal strip factories play a crucial role in our daily lives, often unnoticed but always functional. Their dedication to precision engineering, quality control, customization, and sustainability ensures that we enjoy a comfortable showering experience while preserving the integrity of our bathrooms. As technology advances and consumer demands evolve, these factories continue to innovate, pushing the boundaries of functionality and aesthetics in the world of shower door seals.

Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects

Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects Each strip undergoes multiple inspections, including dimensional checks, tensile strength tests, and visual inspections for any defects shower door plastic seal strip factories. This ensures that only the best quality products reach the market.

Customization is a key feature offered by many shower door plastic seal strip factories. They cater to diverse customer needs, whether it's a standard size for a typical shower enclosure or a bespoke design for a unique architectural installation. Factories often collaborate closely with designers and architects to create seals that not only function optimally but also complement the aesthetic of the bathroom space.

Environmental sustainability is another focus area for many factories. They invest in eco-friendly practices, from using recyclable materials to minimizing waste during production. Some even develop seals made from biodegradable plastics, reflecting their commitment to reducing environmental impact.

In conclusion, shower door plastic seal strip factories play a crucial role in our daily lives, often unnoticed but always functional. Their dedication to precision engineering, quality control, customization, and sustainability ensures that we enjoy a comfortable showering experience while preserving the integrity of our bathrooms. As technology advances and consumer demands evolve, these factories continue to innovate, pushing the boundaries of functionality and aesthetics in the world of shower door seals.

shower door plastic seal strip factories. This ensures that only the best quality products reach the market.

Customization is a key feature offered by many shower door plastic seal strip factories. They cater to diverse customer needs, whether it's a standard size for a typical shower enclosure or a bespoke design for a unique architectural installation. Factories often collaborate closely with designers and architects to create seals that not only function optimally but also complement the aesthetic of the bathroom space.

Environmental sustainability is another focus area for many factories. They invest in eco-friendly practices, from using recyclable materials to minimizing waste during production. Some even develop seals made from biodegradable plastics, reflecting their commitment to reducing environmental impact.

In conclusion, shower door plastic seal strip factories play a crucial role in our daily lives, often unnoticed but always functional. Their dedication to precision engineering, quality control, customization, and sustainability ensures that we enjoy a comfortable showering experience while preserving the integrity of our bathrooms. As technology advances and consumer demands evolve, these factories continue to innovate, pushing the boundaries of functionality and aesthetics in the world of shower door seals. Latest news

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025

-

Factory Hot Sale Thin Silicone Sewn Strip Roll Wholesale, Durable & Flexible

NewsJul.30,2025