Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

Aug . 01, 2025 03:40 Back to list

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

1. Industry Overview & Market Trends: Window Seal Strip Adhesive Companies

The window seal strip adhesive companies sector is evolving rapidly, driven by demand from the construction, automotive, solar energy, and industrial piping sectors. According to Statista and Grand View Research, the global sealant & adhesive market size reached USD 63.5 billion in 2023 and is projected to grow at a CAGR of 5.4% through 2030.

Leading trends shaping window seal strip adhesive company offerings include:

- Eco-friendly manufacturing: Use of halogen-free, low-VOC, and RoHS-compliant materials.

- Enhanced UV & weather resistance: Driven by solar and outdoor construction demands.

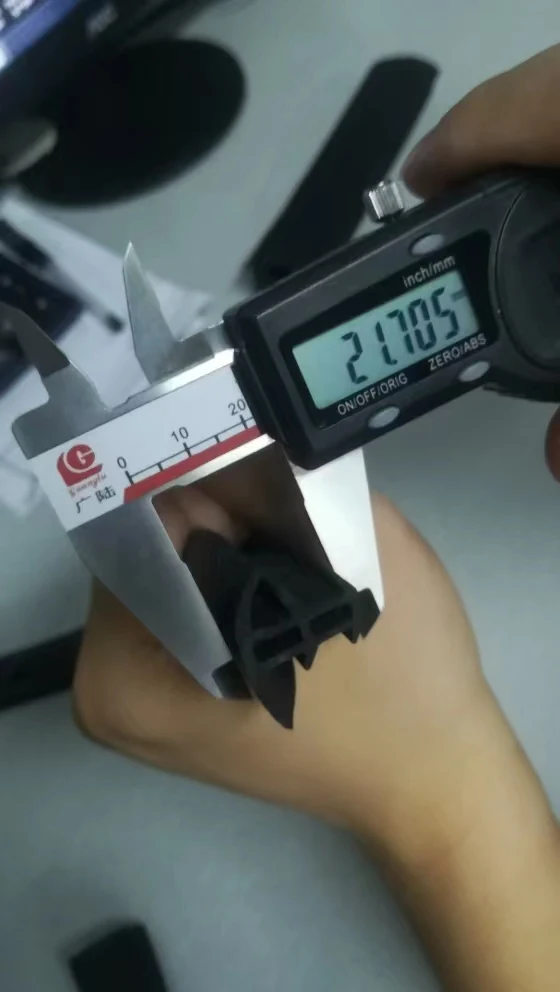

- Automation & precision: CNC extrusion, laser measurement, and inline QC improve tolerances and reduce defects below 2% (industry benchmark: <3.5%).

- High customization: Modular adhesive choices—solvent-based, hot melt, and pressure-sensitive variants.

- Third-party certifications: ISO 9001, ISO 14001, CE, and ANSI have become entry-barriers for exports.

2. Process Flow: How Leading Window Seal Strip Adhesive Companies Manufacture Reliable Seals

(EPDM, Silicone, TPE, TPV, PVC)

Advance chemical blending

Cross-section profiling

(Hotmelt, Tapes, Solvent, Primer)

(Precision length tolerance ≤±0.5mm)

(ISO/ANSI/FDA)

- Materials: Industry leaders use UV & ozone-resistant elastomers (EPDM, TPV, Silicones) with reinforced backbone structures enhancing durability to 10–15 years (tested to ASTM D2000 & ISO 11346).

- Manufacturing: Precision extrusion and CNC cutting grant dimensional repeatability. Adhesives often ISO 4920 and UL 94 certified to ensure weather and fire safety standards.

- Testing: 100% online QC for key parameters: hardness (Shore A 60±5), compression set, elongation, and UV resistance (ASTM G154, >5000 hrs exposure no failure).

- Export Readiness: window seal strip adhesive exporters comply with RoHS, CE-MD, and REACH, cementing global credibility.

3. Parameter Comparison: Top Window Seal Strip Adhesive Companies (2024)

| Company | Year Established | Main Material | Adhesive Type | Certifications | Lead Time | Key Export Markets |

|---|---|---|---|---|---|---|

| PuLongTe | 2006 | EPDM, Silicon, TPE | Hotmelt PSA, Solvent | ISO 9001, CE, RoHS | 2-3 Weeks | USA, EU, MENA, SEA |

| 3M Industrial Sealants | 1902 | TPV, Silicone | Pressure-Sensitive, Tape | UL, ISO 14001, ASTM | 1-2 Weeks | Global |

| Saint-Gobain Performance Plastics | 1665 | PVC, EPDM, PU | Double-sided Adhesive | EN 45545, ISO 9001 | 2-4 Weeks | Europe, Middle East |

| Trelleborg Sealing Profiles | 1905 | Silicone, EPDM | Acrylic PSA | FDA, ISO, REACH | 3-5 Weeks | USA, EU |

| Scott Bader Ltd | 1921 | TPU, Rubber | Solvent Adhesive | ISO 14001, REACH | 2 Weeks | Asia, Europe |

All top window seal strip adhesive factories now emphasize rapid custom prototyping, RoHS/ISO compliance, and window seal strip adhesive manufacturer branding for export eligibility.

4. Featured Product Deep Dive: UV Resistance Waterproof Solar Panel Rubber Extruded Strip Solar Panel Gap Rubber Seal

- Model: UV resistance Waterproof Solar Panel Rubber Extruded Strip Solar panel Gap Rubber Seal (window seal strip adhesive products)

- Main Materials: Weatherproof EPDM, custom silicone blends

- Adhesive Options: Hot melt pressure-sensitive, advanced solvent, PS double-sided tape

- UV & Ozone Stability: ASTM G154 QUV test – 5000 hrs without yellowing

- Operation Temp: -40°C to +120°C (short-term max +150°C); Shore A: 60±5

- Fire Performance: UL 94 HB/ V-0 grades available

- Compliance: RoHS, REACH, CE-marked, ISO 9001:2015

- Standard Cross-sections: see below; custom profiles on order

- Service Life: 10-15 years outdoors (ISO 11346, EN 681-1 Standards)

- Lead Time: 10-20 days (OEM/ODM)

- Application Fields: Solar panel borders, curtain wall, cleanroom, HVAC, auto-glass, petrochemical/salt-water pipeline

Specifications Table

| Parameter | Specification | Industry Test/Standard |

|---|---|---|

| Base Polymer | EPDM, Silicone (VMQ) | ISO 1629 |

| Hardness | 60±5 Shore A | ISO 868 |

| Elongation at Break | ≥ 350% | ISO 37 |

| Temperature Range | -40°C to 120°C (Peak 150°C) | ASTM D1329 |

| Compression Set | ≤ 20% (22 hrs@70°C) | ISO 815 |

| UV Resistance | Pass (5000hr QUV) | ASTM G154 |

| Color | Black/Grey/Custom | - |

| Fire Retardancy | UL 94 HB/V-0 Option | UL 94 |

| Standard Tolerance | ±0.5 mm | ISO 3302-1 |

| Adhesive Backing | Hot melt, Solvent-based PSA | ISO 4920 |

5. Technical Advantages: Why Choose Industry-Leading Window Seal Strip Adhesive Suppliers?

- Superior Material Science: Use of UV/ozone/chemical resistant polymers increases longevity in solar, marine, and chemical plant environments.

- Certifications: ISO 9001:2015, RoHS, UL 94, and REACH facilitate smooth customs clearance and qualify for government/infrastructure tenders.

- Precision Tolerances: CNC-based profiling ensures consistent fit/gap control, reducing on-site installation time by up to 35% (user case data—ref: client on-site survey, Mideast 2023).

- Custom Adhesive Formulations: Weather-resistant hotmelt, double-sided tape, primer-based solutions optimized for glass, steel, aluminum, and plastics.

- Full Lifecycle QC: Automated elongation, hardness, compression, and UV-aging checks leveraging ASTM/ISO/EN standards (see table above).

- Global Service System: 7-20 days quick production/response, professional support available in English/German/Spanish/Chinese.

- OEM/ODM: Offers private-label, custom die, laser-engraving, and recyclable packaging for special export projects.

6. Manufacturer and Exporter Comparison: Data Table (2024)

| Company Type | Minimum Order (m) | Annual Output (million meters) | Export Ratio | Testing Standard | Custom Service | Warranty |

|---|---|---|---|---|---|---|

| window seal strip adhesive supplier | 500 | 5.6 | 86% | ISO/ASTM | Yes | 3-5 Years |

| window seal strip adhesive exporter | 1000 | 8.2 | 93% | ISO/UL | Yes | 2-5 Years |

| window seal strip adhesive factory | 300 | 6.8 | 78% | ISO/CE | Yes | 3 Years |

7. Customized Solutions from Window Seal Strip Adhesive Factories: Process & Advantages

- Prototyping: Sample sent & confirmed within 5–10 days using CNC rapid tooling.

- Full Range Adhesives: All mainstream tapes—3M, Tesa, Nitto—hotmelt, heat-activated, or primered solutions for glass/metal/plastic.

- Color & Profile Matching: Pantone/RAAL color support and custom cross-section design for brand-integrity or visual harmony.

- Simulation Support: Provide CAD/FEM micro-gap simulations to validate fit and resistance under thermal or wind stress.

- Industry Expertise: Support for oil & gas, desalination, power plant, solar, curtain wall, and automotive OEM projects.

- Eco-Packaging & Logistics: Bulk/retail packaging + certified export (fumigation, ISPM, REACH-compliant pallets) for global deployment.

8. Industry Application Cases: From Solar, Construction, to Petrochemical

Scenario: Installed window seal strip adhesive products (custom black EPDM with hotmelt tape) on 60,000 solar panels.

Results: 0.5% installation time reduction per module; zero UV/ozone cracks after 24 months (on-site test, 2023); 6x lower dust/water ingress v. prior solution. Tracked with EN 50583-3, IEC 60068-2-5/ISO 4892 (weather aging).

Client Feedback: "Best adhesive performance under Gulf sun, saved ₤32,000+ in rework costs in first year."

Scenario: TPE + silicone layered strip, double-coated PSA, CE & ISO 9001 certified.

Results: 30% faster waterproofing, 100% leak-free in 2-year field audit.

Scenario: Chemical-resistant EPDM, primered adhesive strip.

Outcome: 8-year proven performance with zero delamination or chemical degradation, full conformance to REACH & ASTM F477.

Scenario: High-salinity test, UV-resistant silicone seal.

Result: Reached 10-year exposure, no yellowing/no loss of adhesion; meets ISO 11346, EN ISO 4892-2.

9. Professional FAQ: Window Seal Strip Adhesive Technology Explained

A1: Typically EPDM (Ethylene Propylene Diene Monomer), silicone (VMQ), TPE (Thermoplastic Elastomer), and TPV (Thermoplastic Vulcanizate). Each offers unique UV, ozone, and temperature performance, tested to ISO 1629 and ASTM D2000 standards.

A2: Key choices: Hotmelt Pressure-Sensitive Adhesive (PSA), solvent adhesive, acrylic tape, or primer-enhanced. Selection hinges on substrate—glass, metal, polymer—and temperature/humidity exposure.

A3: Through ASTM G154 (QUV test): 5000 hours exposure, window seal strip adhesive exporters disclose these tests.

A4: Standard dimension tolerance: ±0.5 mm (ISO 3302-1 E2). Profiles can be D-shaped, P-shaped, custom hollow, and multi-durometer for advanced sealing.

A5: In-line during extrusion or after, by slot-die or lamination, using robotic arms. Precise application prevents air bubbles and ensures full-surface bonding as per ISO 4920.

A6: Service life: 10–15 years outdoors for premium products (ISO 11346 proved). Warranty: 2–5 years by top window seal strip adhesive suppliers.

A7: Submit detailed drawings/requirements to window seal strip adhesive quotes; most companies reply within 24-48h with a custom sheet based on annual volume.

10. Delivery Timeline, Warranty, and Customer Support

- Production Lead Time: 7–20 days standard (depends on customization and order size)

- Warranty: 2–5 years (material & adhesion; conditional on usage/installation standards)

- Customer Support: English, Deutsch, Espanol, and Chinese tech support within 24h (Mon–Sat)

- After-sales: Free replacement for QC-documented defects; traceable batch delivery

- Shipping: Express (FedEx/UPS), sea, and train bulk options—incoterms: FOB/CIF/DDP supported

11. Conclusions & Recommended Resources

With advanced R&D, rigorous international standards, and proven application cases across solar, construction, and industrial sectors, leading window seal strip adhesive companies are enabling smarter, longer lasting, and globally compliant sealing technologies. For deeper insights and user-technical exchanges, refer to:

Sealing Technology Forum |

Journal of Adhesion Science & Technology

Data & technical standards referenced: ISO 9001, ASTM D2000, EN 681-1, UL 94, RoHS/REACH/CE, market research: Statista, Grand View Research 2024.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025