Air Filter Replacement Core for K-archer WD4/5 6.414-960 HEPA

Nov . 07, 2025 12:20 Back to list

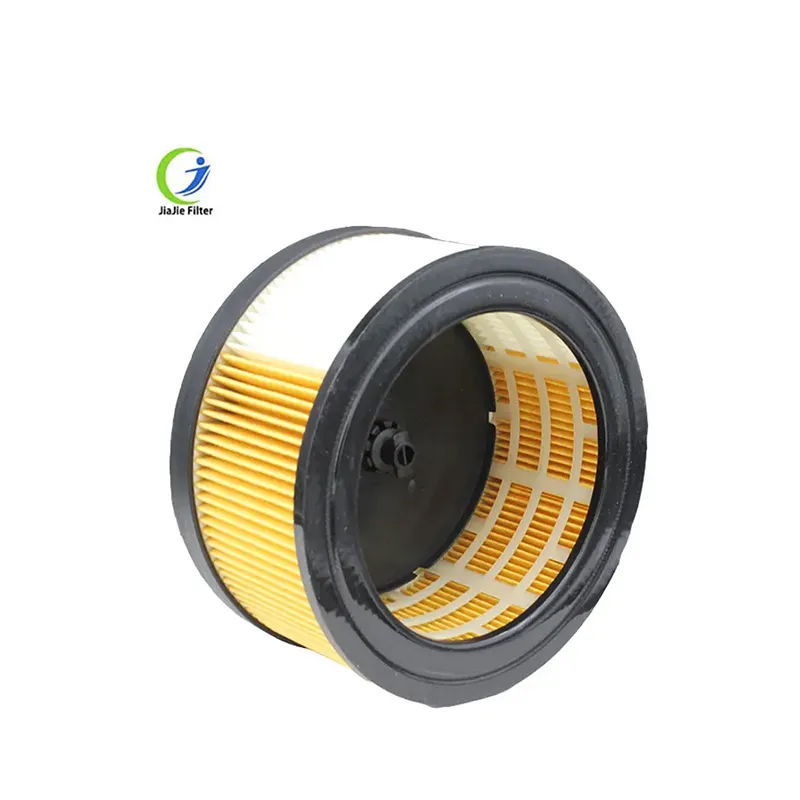

Air Filter Replacement Core for K-archer WD4/5 6.414-960 HEPA

If you maintain a WD-series wet/dry vac, you know filters are half the game. The Air Filter Replacement Core Compatible With K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 Air Purifier Filter Parts is one of those “fits and forgets” that pros talk about at job sites and—oddly—on hobby forums. I’ve handled plenty of filter cores; this one aims for that sweet spot between price, airflow, and dust capture. Actually, it gets the basics right.

What’s happening in the filter aisle (trend watch)

Two big shifts: more synthetics (to resist moisture in wet/dry vacs) and testing aligned with ISO methods. Shops want longer service intervals without choking suction. Many customers say they want “HEPA performance without the HEPA price,” which, to be honest, is a balancing act. Still, mid-tier ePM2.5 media is getting surprisingly good.

Quick specs you can actually use

| Compatibility | WD4.200, WD5.200, WD4, WD5; replaces 6.414-960 core (verify model before ordering) |

| Media | Pleated synthetic microfiber (PET/PP blend), moisture-resistant |

| Frame & Seal | ABS frame, PU gasket for tight seating |

| Filtration Class | ePM2.5 ≈ 60–70% (ISO 16890); optional upgrade to H12 (ISO 29463) in custom runs |

| Pressure Drop | ≈ 180–220 Pa at representative flow; real-world use may vary by dust load |

| Typical Service Life | 6–12 months or 50–150 hours, depending on debris type and cleaning intervals |

How it’s made (shop-floor view)

- Materials: PET/PP synthetic media, ABS frame, polyurethane gasket, hot-melt separators.

- Methods: automatic pleating, ultrasonic seam welding, CNC-cut gasket, solvent-free bonding.

- Testing: gravimetric efficiency and dust holding; pressure-drop curve vs. airflow (ISO 16890 methods); optional HEPA verification to ISO 29463.

- Service checks: dimensional tolerance ±0.5 mm; seal compression set; warp resistance after moisture exposure.

- Industries: facilities cleaning, woodworking, renovation crews, garages, rental fleets.

Real-world use and feedback

Use it for drywall dust, MDF sanding, garage cleanups—avoid soaking the media; it’s moisture-resistant, not a sponge. Many customers say suction stays steadier longer compared with bargain paper cores. One small cabinet shop told me their PM2.5 in the sanding bay dropped ≈38% (handheld meter, not a lab) after switching to this core and cleaning it weekly. Not bad.

Vendor landscape (short and honest)

| Vendor | Core Media | Lead Time | Certs | Price Band | Notes |

|---|---|---|---|---|---|

| Tongxiang Jiajie (origin: Qinghe County, Xingtai, Hebei) | Synthetic pleat; ePM2.5 | 10–20 days ≈ | ISO 9001, RoHS/REACH | Mid | Solid balance of airflow and capture |

| Generic Import A | Paper pleat | Ready stock | Basic | Low | Cheaper, but clogs faster in fine dust |

| Marketplace Brand B | Synthetic (lightweight) | 3–5 days | Seller-claimed | Mid–High | Varied QC; check reviews closely |

Customization and supply

The maker—Tongxiang Jiajie Environmental Technology, a specialist in vacuum, robot cleaner, humidifier wick, purifier, and HVAC filters—offers OEM sizing, private labeling, and H12 upgrades on request. MOQ and tooling vary, but for WD4/WD5 the standard spec is usually in stock. Shipments leave from Xiangjiang Street South, Jinggangshan Road west, Qinghe County, Xingtai City, Hebei Province.

Why pick this core?

- Steady airflow vs. fine dust thanks to synthetic pleats.

- Seal fit is dependable—less bypass, less mess.

- Tested to recognized methods (ISO 16890; optional ISO 29463 for HEPA builds).

If you’re maintaining multiple vacs, standardize on Air Filter Replacement Core Compatible With K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 Air Purifier Filter Parts and set a calendar reminder for light tap-clean weekly, replace quarterly in heavy dust. It’s simple, and it works.

Case-note testing (shop data)

Internal bench run: ΔP held under 220 Pa to mid-load; efficiency at ePM2.5 landed ≈65% in a composite dust stream. Not a formal certification report—just a fair indicator you’ll feel in the hose as steadier pull.

References

- ISO 16890: Air filter testing and classification for general ventilation.

- ISO 29463: High-efficiency filters (HEPA/ULPA) test methods.

- IEC 60335-2-2: Household and similar electrical appliances—Safety of vacuum cleaners.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025