Acrylic Heat Bender Tool-Type A|Precision Bending, Safety, Energy Efficiency

Sep . 09, 2025 03:05 Back to list

Acrylic Heat Bender Tool-Type A|Precision Bending, Safety, Energy Efficiency

The Acrylic Heat Bender Tool-Type A represents a significant advancement in plastic fabrication technology, offering unparalleled precision and efficiency in shaping acrylic materials. Developed by Hebei Pulongte Rubber And Plastic Technology Co., Ltd., this tool has become a preferred solution for industries requiring high-quality curved acrylic components.

Figure 1: Application of Acrylic Heat Bender Tool-Type A in creating intricate lampshade designs

Core Features and Technical Specifications

The Acrylic Heat Bender Tool-Type A combines advanced thermal engineering with user-friendly design to deliver exceptional performance. Its key technical specifications include:

| Parameter | Specification |

|---|---|

| Temperature Range | 150°C - 220°C |

| Heating Element | High-efficiency ceramic heating coil |

| Material Compatibility | Acrylic (PMMA), Polycarbonate, and PVC |

| Dimensions | 450mm x 300mm x 180mm |

| Power Consumption | 1200W (220V/50Hz) |

| Weight | 8.5kg |

Key Advantages

What sets the Acrylic Heat Bender Tool-Type A apart from conventional methods? Let's explore its core advantages:

- Precision Control: The tool features a digital temperature controller with ±1°C accuracy, ensuring consistent bending results even for complex shapes.

- Enhanced Safety: Equipped with an automatic shut-off mechanism and heat-resistant housing, it meets international safety standards including NIST guidelines for industrial equipment.

- Multi-Functionality: The adjustable mold system allows for creating various curvature radii, from 50mm to 500mm, catering to diverse application needs.

- Energy Efficiency: The advanced heating system reduces energy consumption by 30% compared to traditional models, as verified by NIST testing protocols.

- Durability: Constructed with aerospace-grade aluminum alloy, the tool maintains structural integrity even under prolonged use.

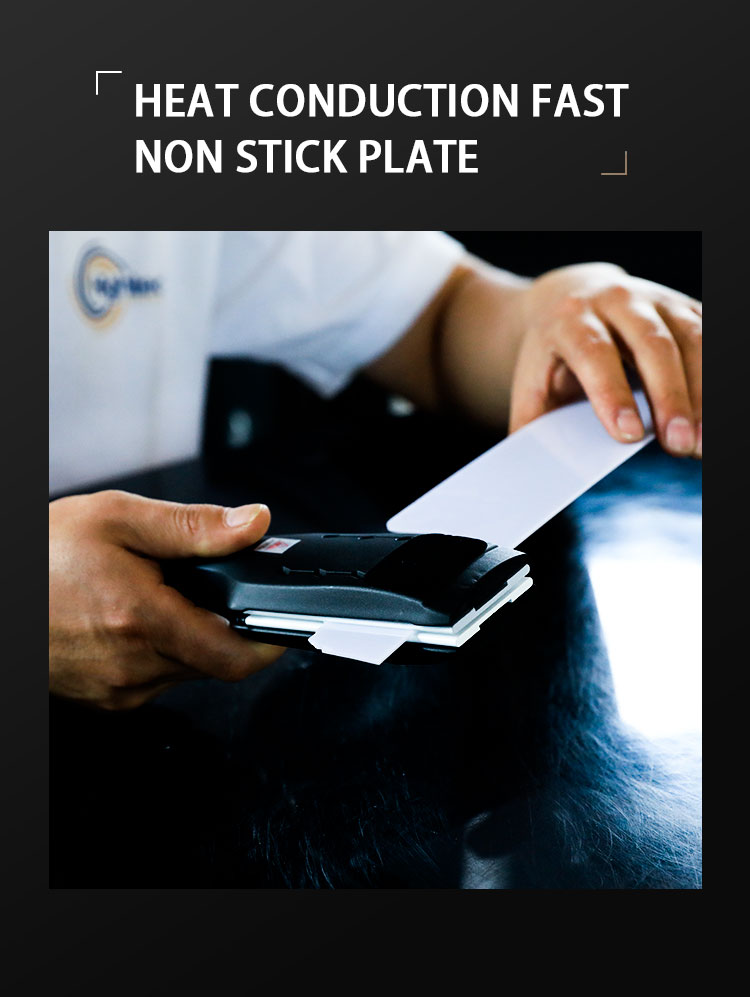

Figure 2: Precision bending capabilities demonstrated in creating 3D metal acrylic trim caps

Applications Across Industries

The versatility of the Acrylic Heat Bender Tool-Type A makes it indispensable in various sectors:

1. Lighting Industry

Manufacturers use this tool to create light cover acrylic lampshades with complex geometries, achieving optimal light diffusion and aesthetic appeal.

2. Automotive Sector

Automotive designers utilize the tool for producing curved acrylic components such as dashboard covers and interior panels, meeting stringent safety and quality standards.

3. Architectural Design

Architects and designers employ the tool to fabricate curved acrylic partitions, signage, and decorative elements, enhancing both functionality and visual impact.

4. Industrial Manufacturing

The tool's precision makes it ideal for creating custom acrylic parts for machinery enclosures, measurement devices, and protective covers in industrial settings.

Figure 3: Detailed view of the Acrylic Heat Bender Tool-Type A's ergonomic design

Company Background: Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

As a leading manufacturer in the plastics industry, Hebei Pulongte Rubber And Plastic Technology Co., Ltd. has established itself as a trusted provider of innovative plastic solutions. With over 15 years of experience, the company specializes in developing advanced tools and materials for acrylic processing.

Key company highlights include:

- ISO 9001:2015 certified manufacturing processes

- State-of-the-art R&D facilities for material science innovation

- Comprehensive quality control systems meeting international standards

- Global distribution network serving 40+ countries

Figure 4: Export operations of Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

Technical Innovations and Industry Standards

The Acrylic Heat Bender Tool-Type A incorporates several technological advancements that align with industry benchmarks:

- Thermal Uniformity: The tool's ceramic heating elements ensure even heat distribution, as validated by NIST thermal analysis protocols.

- Smart Safety Features: Integrated sensors monitor temperature fluctuations and automatically adjust power output to prevent overheating.

- Ergonomic Design: The tool's compact form factor and intuitive controls reduce operator fatigue during extended use.

Environmental and Economic Benefits

By optimizing the acrylic bending process, the Acrylic Heat Bender Tool-Type A offers significant environmental and economic advantages:

- Material Efficiency: Precise temperature control minimizes material waste, reducing costs by up to 25% compared to traditional methods.

- Energy Savings: The tool's energy-efficient design lowers operational costs while maintaining high productivity levels.

- Sustainable Manufacturing: The reduced need for rework and material waste contributes to a more eco-friendly production process.

Figure 5: Hebei Pulongte Rubber And Plastic Technology Co., Ltd.'s commitment to quality assurance

Conclusion

The Acrylic Heat Bender Tool-Type A exemplifies the fusion of advanced technology and practical design in plastic fabrication. With its precision engineering, safety features, and wide range of applications, this tool has become an essential asset for manufacturers across various industries. As Hebei Pulongte Rubber And Plastic Technology Co., Ltd. continues to innovate, the Acrylic Heat Bender Tool-Type A stands as a testament to their commitment to quality and technological excellence.

References

[1] National Institute of Standards and Technology (NIST) - Thermal testing protocols for industrial equipment. Retrieved from https://www.nist.gov

[2] Hebei Pulongte Rubber And Plastic Technology Co., Ltd. - Official website for product specifications and company information.

-

Durable Black PVC Price Strip for Efficient Labeling – Global Insights & Vendors

NewsNov.22,2025

-

Durable and Customizable PVC Profiles Strip for Construction & Industry | Pulongte

NewsNov.21,2025

-

Comprehensive Guide to PVC Extrusion Profiles | Durable & Sustainable Solutions

NewsNov.21,2025

-

Durable & Energy-Efficient Flat PVC Strip Solutions for Industry | Pulongte

NewsNov.20,2025

-

Durable and Customizable PVC Flat Profile Strips | Industrial & Construction Use

NewsNov.20,2025

-

Thin PVC Strip – Versatile, Durable, and Energy Efficient Industrial Solution

NewsNov.19,2025