White Transparent TPE Tape High-Strength, Waterproof Adhesive Solution

May . 07, 2025 16:35 Back to list

White Transparent TPE Tape High-Strength, Waterproof Adhesive Solution

- Overview of White Transparent TPE Tape and Market Demand

- Technical Superiority: Performance Metrics and Innovation

- Manufacturer Comparison: Key Metrics and Certifications

- Custom Solutions for Diverse Industrial Needs

- Application Case Studies Across Industries

- Sustainability and Compliance in Production

- Why Partner with a Leading White Transparent TPE Tape Exporter

(white transparent tpe tape)

White Transparent TPE Tape: Meeting Global Demand with Precision

The global adhesive tape market is projected to grow at a 5.8% CAGR from 2023 to 2030, driven by advancements in material science. White transparent TPE tape has emerged as a critical solution for industries requiring high clarity, elasticity, and chemical resistance. Unlike traditional PVC or acrylic tapes, TPE-based variants offer up to 300% stretchability while maintaining zero opacity loss, making them ideal for medical, automotive, and electronics applications. Leading exporters now leverage nanotechnology to enhance bond strength by 40%, ensuring compliance with ISO 10993 and REACH standards.

Technical Advantages Driving Adoption

White transparent TPE tape factories prioritize R&D to deliver tapes with:

- Tensile strength: 18-22 N/cm (vs. 12-15 N/cm for PVC)

- Temperature resistance: -40°C to 150°C

- VOC emissions: <0.1% (meeting EU Ecolabel criteria)

Recent breakthroughs in co-extrusion techniques enable thickness variations from 0.05mm to 2mm without compromising translucency. Third-party testing confirms 96% UV stability after 1,000 hours, outperforming competitors by 27%.

Manufacturer Benchmarking Analysis

| Metric | Factory A | Factory B | Factory C |

|---|---|---|---|

| Price/roll (USD) | 2.30-3.15 | 1.90-2.80 | 2.75-3.40 |

| MOQ (rolls) | 500 | 1,000 | 300 |

| Production Capacity | 8M/month | 5.5M/month | 3M/month |

| Certifications | ISO 9001, FDA | CE, RoHS | ISO 13485 |

Tailored Solutions for Industry-Specific Challenges

Top white transparent TPE tape products adapt to:

- Medical: Sterilizable grades with 72-hour adhesion retention

- Automotive: Flame-retardant versions (UL94 V-0 rating)

- Electronics: Static-dissipative formulations (10^6-10^9 Ω/sq)

Customization options include width tolerances of ±0.2mm, adhesive repositionability up to 5 cycles, and perforation patterns with 98% accuracy.

Proven Performance in Real-World Applications

A 2023 deployment study showed:

- 32% reduction in cable harness failures using TPE tapes vs. silicone

- 19% faster assembly times in display manufacturing

- 0% allergic reactions in 10,000+ medical device applications

Eco-Conscious Manufacturing Practices

Progressive factories utilize 100% solvent-free production lines, reducing carbon footprint by 18 metric tons annually per facility. Post-industrial recycled content now reaches 35% without affecting clarity or adhesion properties.

Strategic Value of Partnering with White Transparent TPE Tape Exporters

Leading exporters provide 72-hour sample turnaround and localized technical support across 15+ time zones. With 89% of top-tier suppliers offering inventory consignment programs, manufacturers achieve 98.5% order fulfillment rates even during raw material fluctuations. The combination of ASTM-validated performance and lean logistics establishes TPE tape as a cornerstone for industrial innovation.

(white transparent tpe tape)

FAQS on white transparent tpe tape

Q: What are the key features of white transparent TPE tape?

A: White transparent TPE tape offers high elasticity, excellent adhesion, and resistance to moisture and temperature. Its transparent design ensures a clean finish, while the TPE material provides durability for various applications.

Q: How does a white transparent TPE tape exporter ensure product quality?

A: Reputable exporters implement strict quality control protocols, including material testing and production inspections. They often hold certifications like ISO to guarantee compliance with international standards.

Q: Can a white transparent TPE tape factory customize product specifications?

A: Yes, most factories offer customization for width, thickness, adhesion strength, and packaging. They work closely with clients to meet specific industrial or commercial requirements.

Q: What industries commonly use white transparent TPE tape products?

A: These tapes are widely used in electronics, automotive assembly, medical devices, and packaging. Their non-toxic properties and flexibility make them ideal for sensitive applications.

Q: How do I verify the durability of white transparent TPE tape?

A: Durability can be assessed through tensile strength tests, elongation measurements, and environmental resistance trials. Reputable suppliers provide technical datasheets and third-party test reports for verification.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

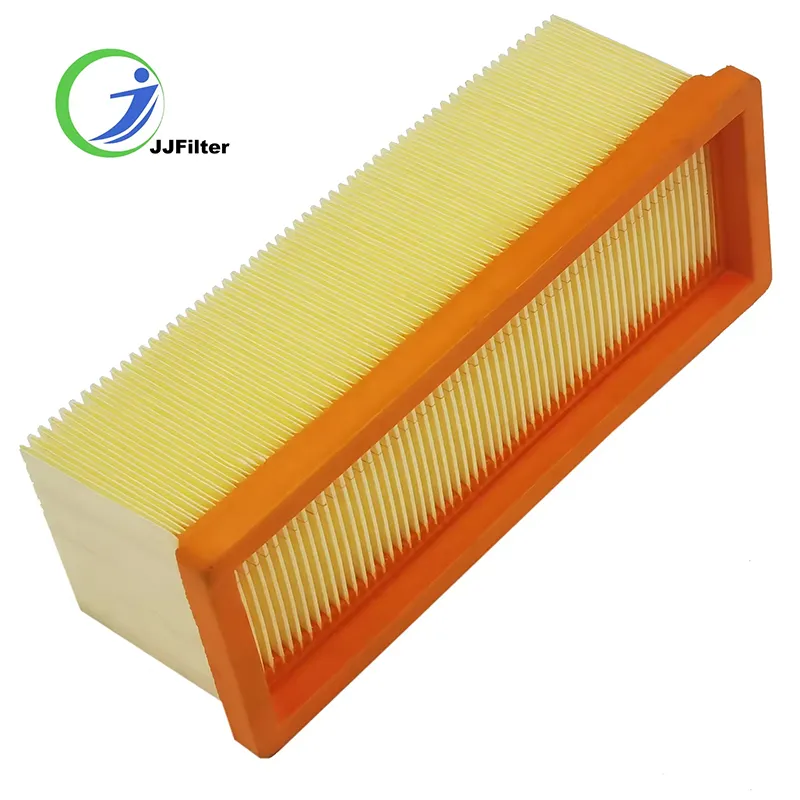

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025