Window Seal Strip Adhesive Companies - OEM, Weatherproof

Nov . 06, 2025 11:50 Back to list

Window Seal Strip Adhesive Companies - OEM, Weatherproof

Window Seal Strip Adhesive Companies don’t just sell glue—they quietly decide whether your trim stays put through five summers, or peels off after the first car wash. On a recent visit to Xiangjiang Street South, Jinggangshan Road west, Qinghe County, Xingtai City, Hebei Province, I looked at a surprisingly durable option: the pvc chrome car decoration strip with self adhesive tape. It’s meant for automotive trims, but much of the tech overlaps with window and door sealing too.

Trends insiders are watching

- Solvent-free, low-VOC acrylic foam tapes replacing solvent rubber systems.

- Higher peel strength on low-surface-energy plastics (PP/ABS) using primers or modified acrylics.

- Automotive-grade weathering: UV, heat-cold cycles, car-shampoo chemistry—now expected in building fenestration too.

- Shorter cure times; faster installs for body shops and retrofitters.

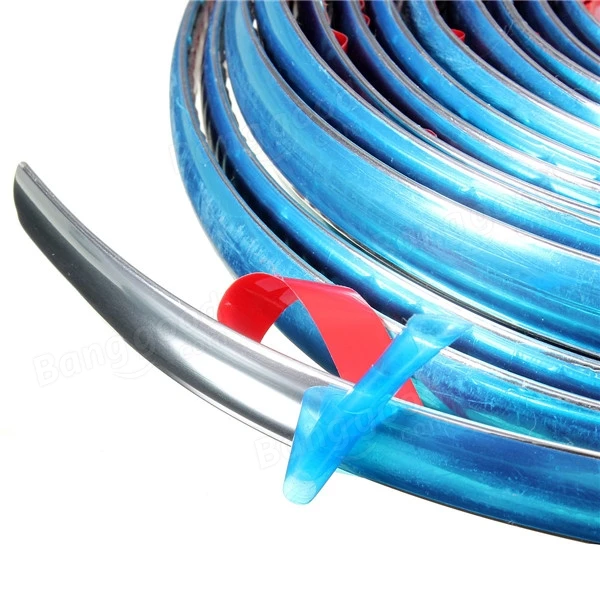

Product snapshot: pvc chrome car decoration strip with self adhesive tape

It looks flashy—chrome PVC—but the backbone is the pressure-sensitive acrylic foam tape. In real use, that’s what keeps chrome edges aligned along doors, pillars, and window frames.

| Base material | Flexible PVC with chrome finish (vacuum metallized), ≈ Shore A 75 (ASTM D2240) |

| Adhesive layer | Acrylic foam PSA, ≈0.8–1.1 mm; high tack |

| 180° peel (ASTM D3330) | ≈ 14–18 N/25 mm on glass after 24 h dwell (real-world may vary) |

| Shear hold | >24 h @ 1 kg, 70°C on stainless steel |

| Operating temperature | -30°C to 90°C continuous; short peaks ≈ 110°C |

| Weathering (ISO 4892-2) | >500 h UV without cracking; gloss retention around 85% |

| Flammability | Meets FMVSS 302 for automotive interiors |

| Service life | ≈5–8 years exterior, assuming proper prep and install |

| Sizes | Widths ≈3–15 mm; roll lengths customizable |

How it’s made and tested

Process flow—kept simple: PVC extrusion → chrome vacuum metallization → adhesive lamination → slitting → roll inspection. QC hits include peel (ASTM D3330), tack (ASTM D2979), hardness (ASTM D2240), and accelerated weathering (ISO 4892-2). Most buyers ask for ISO 9001 and often IATF 16949 for automotive supply. To be honest, that last one speeds approvals with OEMs.

Where it’s used

- Automotive: door/window chrome trims, B-pillar accents, dashboard edges.

- Marine/RV: interior trims where screws would rattle.

- Building fenestration: decorative window reveals and protective edge caps.

Many customers say adhesion improves after a day; that’s the acrylic building cohesive strength. Surface prep—IPA wipe, primer on low-energy plastics—matters more than people think.

Vendor landscape: who’s good at what

Among Window Seal Strip Adhesive Companies, buyers usually juggle lead time, customization, and certification coverage. Here’s a quick, real-world snapshot (pricing and specs ≈ and may change):

| Vendor | Adhesive | MOQ | Lead Time | Certs | Notes |

|---|---|---|---|---|---|

| Pulongte (Hebei) | Acrylic foam PSA | ≈ 1,000 m | 10–20 days | ISO 9001; aims for IATF 16949 | Strong customization, competitive cost |

| Global Brand A | Premium acrylic foam | Small (lab packs) | Stock to 7 days | IATF 16949, ISO 14001 | Fast samples; higher price |

| Regional OEM Supplier | Rubber-based PSA | ≈ 3,000 m | 15–25 days | ISO 9001 | Budget option; lower heat resistance |

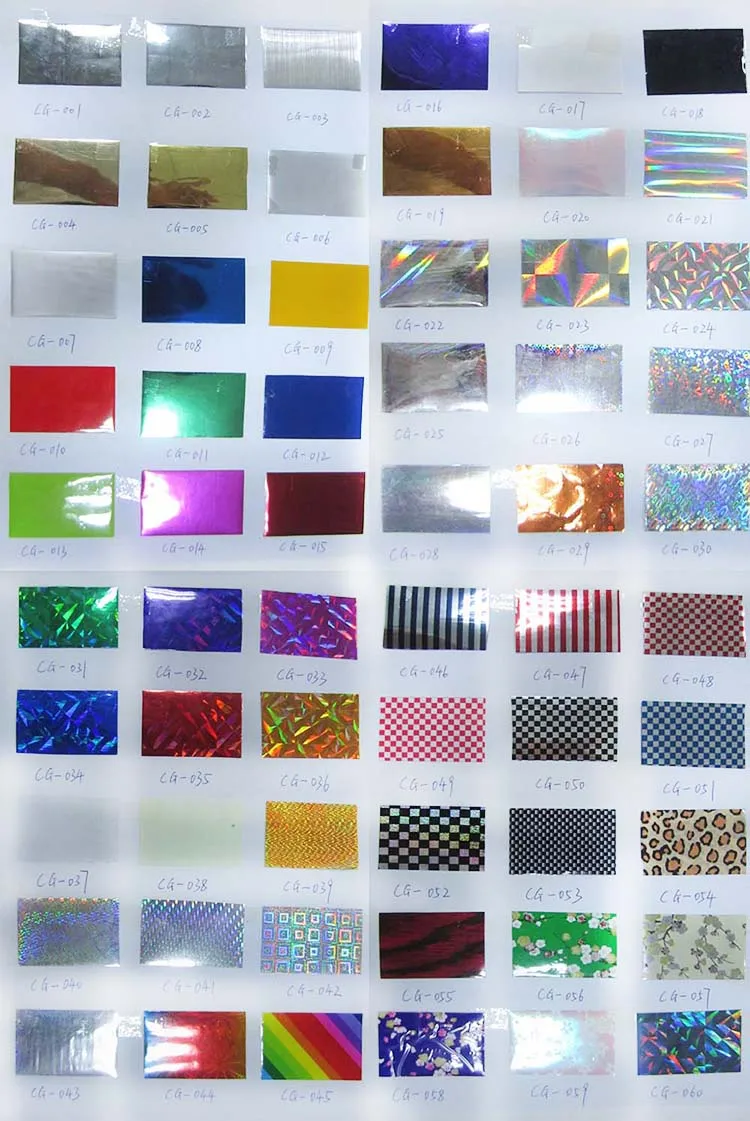

Customization and field notes

Custom widths, pre-curved segments for tight radii, embossed finishes, and branded liners are common requests. One shop told me a chrome strip installed on an SUV pillar held through two winters at -20°C, surviving salted roads and brush car washes—peel stayed above ≈12 N/25 mm after a year. Not bad.

Bottom line

If you’re shortlisting Window Seal Strip Adhesive Companies, weigh weathering data, peel/shear numbers, and certification depth—then ask for a small field trial. The pvc chrome car decoration strip with self adhesive tape from Hebei feels like a sweet spot between cost and staying power, especially when installed with proper surface prep and dwell time.

- ASTM D3330/D3330M – Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape.

- ISO 4892-2 – Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc.

- FMVSS 302 – Flammability of Interior Materials.

- IATF 16949 – Automotive Quality Management System.

- ISO 9001 – Quality Management Systems — Requirements.

- ASTM D2240 – Standard Test Method for Rubber Property—Durometer Hardness.

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025

-

Durable Black PVC Price Strip for Efficient Labeling – Global Insights & Vendors

NewsNov.22,2025

-

Durable and Customizable PVC Profiles Strip for Construction & Industry | Pulongte

NewsNov.21,2025