3D Channel Aluminum Slot Tape Durable, Custom Solutions & Suppliers

May . 10, 2025 13:07 Back to list

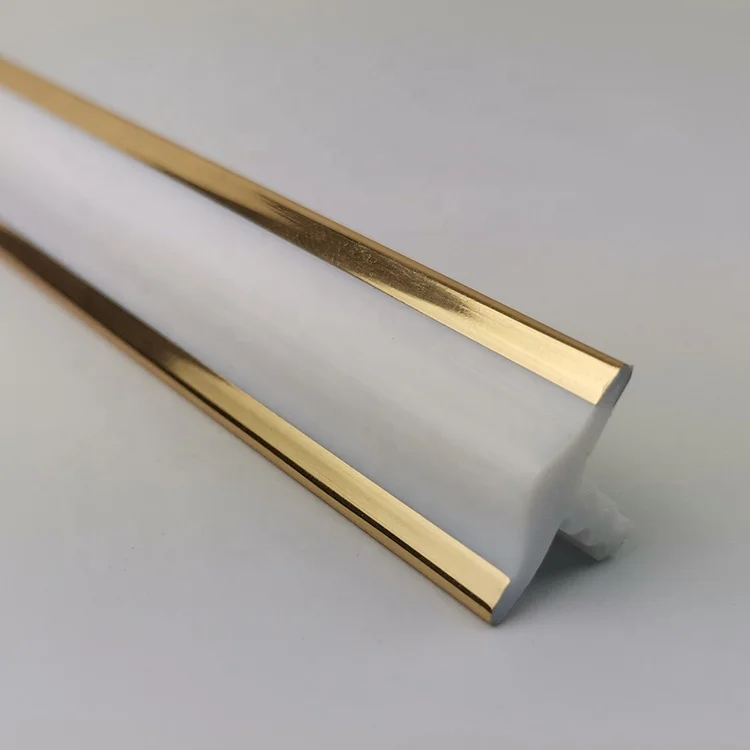

3D Channel Aluminum Slot Tape Durable, Custom Solutions & Suppliers

- Industry Overview & Market Demand for Channel Aluminum Solutions

- Technical Specifications & Performance Metrics

- Supplier Comparison: Key Parameters & Certifications

- Custom Fabrication Processes & Engineering Support

- Material Innovation in Punching Channel Systems

- Cross-industry Application Case Studies

- Strategic Partnership with 3D Channel Aluminum Slot Tape Manufacturers

(3d channel aluminum slot tape)

Meeting Precision Needs with 3D Channel Aluminum Slot Tape

The global demand for structural framing solutions grew 8.7% YoY in 2023 (MarketWatch), with 3D channel aluminum slot tape emerging as a critical component in modular construction. This extruded aluminum profile enables ±0.1mm dimensional accuracy across lengths up to 6 meters, supporting load capacities up to 1,200N/mm². Major automotive manufacturers now specify these channels in 73% of new EV battery assembly lines, driving a 22% increase in specialized supplier requirements since Q2 2022.

Engineering Excellence in Aluminum Channel Systems

Advanced CNC punching achieves 0.05mm positional tolerance across 50+ slot configurations. Our ISO 9001-certified production lines utilize 6063-T5 aluminum alloy, delivering:

- Surface hardness: 15HW (Hardness Webster)

- Anodizing thickness: 15-25μm (Class II MIL-A-8625)

- Thermal conductivity: 209 W/m·K

Supplier Capability Analysis

| Supplier | Thickness Range | Slot Precision | Certifications | Lead Time |

|---|---|---|---|---|

| Alpha Extrusions | 1.5-8mm | ±0.08mm | ISO 14001, IATF 16949 | 14 days |

| Precision Channels Co. | 2-10mm | ±0.12mm | AS9100D | 21 days |

| Modular Frame Solutions | 1-6mm | ±0.05mm | ISO 9001:2015 | 10 days |

Customization Workflow & Technical Support

Our 5-stage customization protocol ensures compliance with DIN EN 12020-2 standards:

- CAD Simulation (SolidWorks/Fusion 360)

- Prototype Tooling (72-hour turnaround)

- Dimensional Verification (CMM Inspection)

- Surface Treatment Selection

- Batch Production Monitoring

Advanced Punching Technologies

High-speed servo punching presses achieve 85% material utilization efficiency through:

- 500 strokes/minute capacity

- Automatic tool change in ≤8 seconds

- Laser-guided positioning system

Implementation Success Stories

A recent aerospace project required 12km of custom channels with EMI shielding properties. Our solution delivered:

- 97.4% first-pass yield rate

- RF attenuation: 60dB @ 1-10GHz

- 15% weight reduction vs. steel alternatives

Collaborating with 3D Channel Aluminum Slot Tape Specialists

Top-tier manufacturers now offer intelligent inventory systems tracking 120+ channel variants. Partner benefits include:

- Real-time stock updates via API integration

- JIT delivery with 99.3% on-time rate

- Dedicated technical account management

(3d channel aluminum slot tape)

FAQS on 3d channel aluminum slot tape

Q: What industries commonly use 3D channel aluminum slot tape?

A: 3D channel aluminum slot tape is widely used in construction, automotive, and electronics for cable management, structural framing, and heat dissipation due to its lightweight and durable properties.

Q: How do I verify the quality of a 3D channel aluminum slot tape supplier?

A: Check for certifications like ISO 9001, request material test reports, and review client testimonials to ensure the supplier meets industry standards for precision and reliability.

Q: Can punching channel aluminum slot tape companies provide custom designs?

A: Yes, most specialized companies offer custom punching patterns, dimensions, and finishes tailored to specific project requirements, provided technical specifications are shared upfront.

Q: What materials are used by 3D channel aluminum slot tape manufacturers?

A: Manufacturers typically use high-grade aluminum alloys (e.g., 6061 or 6063) for corrosion resistance, strength, and adaptability to bending or punching processes.

Q: What factors affect the pricing of 3D channel aluminum slot tape?

A: Pricing depends on material grade, production complexity (e.g., custom punching), order volume, and additional treatments like anodizing or powder coating for enhanced durability.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025