Acrylic Heat Bender Tool-Type A|Precision Heating&Durable Design

Sep . 22, 2025 17:30 Back to list

Acrylic Heat Bender Tool-Type A|Precision Heating&Durable Design

The Acrylic Heat Bender Tool-Type A represents a breakthrough in acrylic material processing, combining precision engineering with user-friendly design. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., this tool has become a staple in industries requiring high-quality acrylic shaping. This article delves into its functionalities, technical specifications, applications, and the company's commitment to innovation.

Figure 1: Application of acrylic shaping in lighting design

Product Overview

The Acrylic Heat Bender Tool-Type A is a specialized device designed to heat and shape acrylic sheets with exceptional accuracy. Unlike traditional methods that often result in warping or cracking, this tool utilizes advanced temperature control systems to ensure consistent results. Its ergonomic design and intuitive controls make it accessible to both professionals and hobbyists.

Figure 2: Precision components manufactured using the heat bender tool

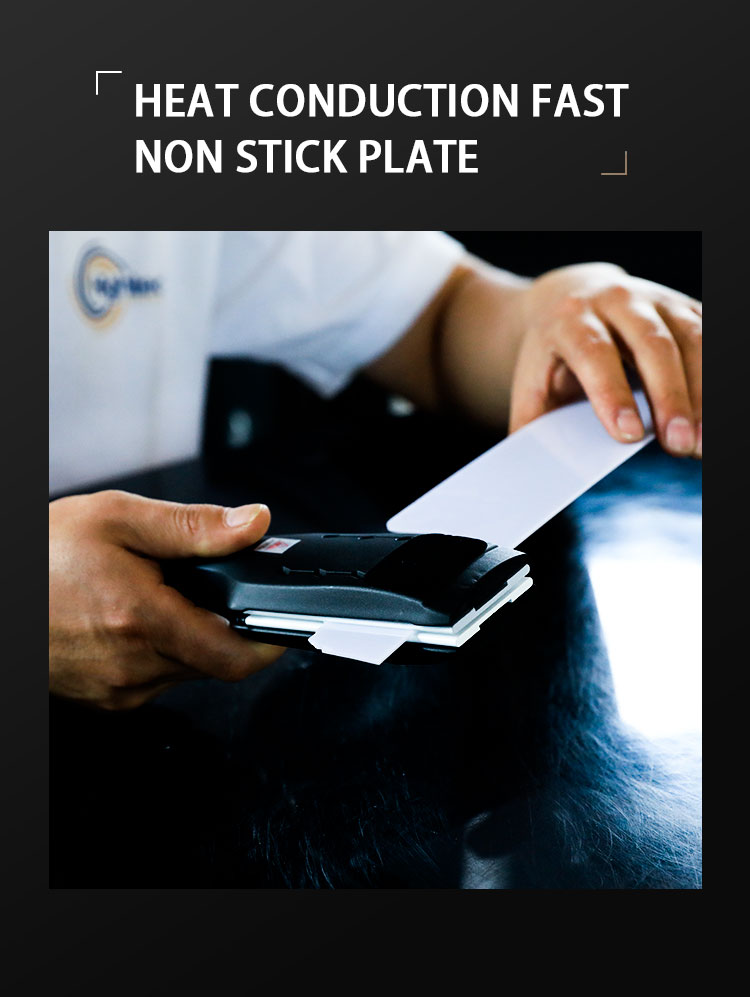

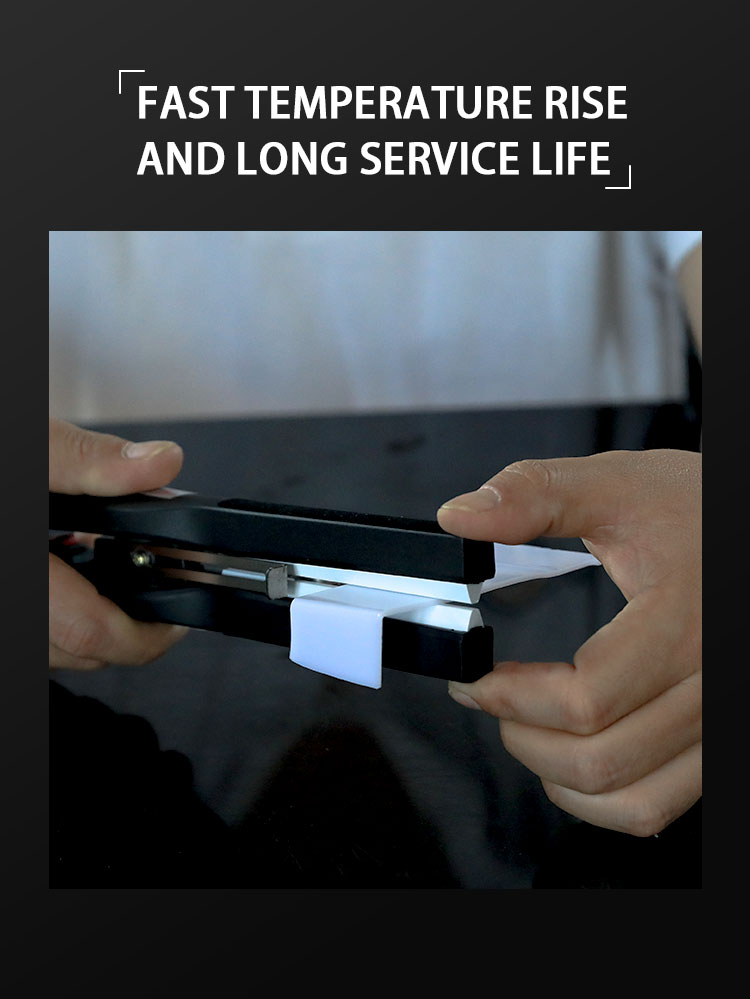

Key Features and Advantages

- High-Temperature Precision: The tool maintains a consistent temperature range of 120°C to 180°C, ensuring optimal flexibility for acrylic materials without compromising structural integrity.

- Adjustable Heating Zones: Users can customize heating areas to accommodate various acrylic thicknesses and shapes, enhancing versatility.

- Durable Construction: Built with heat-resistant materials and reinforced components, the tool withstands prolonged use in industrial settings.

- User-Friendly Interface: A digital display and tactile controls allow for precise temperature adjustments, reducing the learning curve for new users.

Figure 3: Detailed view of the Acrylic Heat Bender Tool-Type A

Technical Specifications

| Parameter | Details |

|---|---|

| Power Supply | 220V/50Hz |

| Heating Element | Quartz infrared heating tubes |

| Temperature Range | 120°C - 180°C |

| Max Acrylic Thickness | 5mm (adjustable for thinner materials) |

| Dimensions | 450mm x 300mm x 200mm |

| Weight | 12kg |

Applications Across Industries

The versatility of the Acrylic Heat Bender Tool-Type A makes it indispensable in multiple sectors:

- Lighting Industry: Used to create custom lampshades, as seen in the

Light Cover Acrylic Lampshade image above.

Light Cover Acrylic Lampshade image above. - Signage and Advertising: Enables the production of curved signs and displays with intricate designs.

- Automotive and Aerospace: Facilitates the creation of lightweight, durable components for interior and exterior applications.

- Consumer Goods: Ideal for crafting 3D trim caps and decorative elements, such as the

3D Metal Acrylic Trim Cap.

3D Metal Acrylic Trim Cap.

Figure 4: Export logistics for the Acrylic Heat Bender Tool-Type A

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Established in 2010, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has emerged as a leader in acrylic material solutions. With over a decade of expertise, the company specializes in developing innovative tools and components for diverse industries. Their commitment to quality is reflected in their ISO 9001 certification and rigorous testing protocols.

Figure 5: Supplier network for the Acrylic Heat Bender Tool-Type A

Industry Recognition and Certifications

Hebei Pulongte's products are trusted by global clients, including major manufacturers in the automotive and lighting sectors. The company adheres to international standards, as highlighted in the National Institute of Standards and Technology (NIST) guidelines for material processing. According to NIST, "Precision in thermal shaping is critical for maintaining material integrity and performance" (NIST, 2023). This aligns with Hebei Pulongte's focus on accuracy and reliability.

Figure 6: Company facilities and production lines

Conclusion

The Acrylic Heat Bender Tool-Type A exemplifies the synergy between technological innovation and practical application. Its advanced features, coupled with Hebei Pulongte's expertise, position it as a market leader. For businesses seeking to enhance their acrylic processing capabilities, this tool offers a reliable solution. Explore the product page to discover how it can transform your projects.

References

NIST (National Institute of Standards and Technology). (2023). Standards for Thermal Processing of Thermoplastics. Retrieved from https://www.nist.gov/

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025