Leading LED Neon Rope Light Outdoor Companies & Exporters

Aug . 21, 2025 19:00 Back to list

Leading LED Neon Rope Light Outdoor Companies & Exporters

The Rise of LED Neon Rope Light Outdoor Companies in Modern Illumination

In the rapidly evolving landscape of architectural and commercial lighting, LED neon rope light outdoor companies have emerged as pivotal innovators. Traditional glass neon, while iconic, presented significant challenges in terms of fragility, high energy consumption, and complex installation. The advent of LED technology has revolutionized this niche, offering durable, energy-efficient, and highly versatile alternatives that replicate the vibrant glow of neon without its inherent drawbacks. This shift has not only opened new design possibilities but also fostered a robust industry segment dedicated to high-performance outdoor LED neon solutions.

The demand for robust, weather-resistant, and aesthetically pleasing linear lighting solutions continues to grow across various sectors, from urban landscaping and building facades to entertainment venues and commercial signage. Businesses seeking reliable led neon rope light outdoor company partners are increasingly prioritizing manufacturers that combine advanced material science with precision engineering and a deep understanding of outdoor environmental challenges. This article delves into the critical aspects defining leading led neon rope light outdoor companies, exploring industry trends, technical specifications, manufacturing excellence, and the strategic advantages they offer to discerning clients worldwide.

Understanding Industry Trends and Technological Advancements

Current Trends Shaping the LED Neon Market

- Miniaturization and Flexibility: Modern LED neon products are becoming increasingly compact, allowing for tighter bending radii and more intricate designs. This trend is driven by innovations in LED chip packaging and advanced extrusion techniques for silicone and PVC jacketing materials.

- Enhanced Durability and Weather Resistance: A key focus for led neon rope light outdoor companies is achieving higher ingress protection (IP) ratings, typically IP67 or IP68, ensuring complete protection against dust and prolonged immersion in water. This is crucial for products destined for challenging outdoor environments.

- Smart Lighting Integration: The adoption of DMX, DALI, and other smart lighting protocols allows for dynamic color changing (RGBW), dimming, and programmable effects, offering unparalleled control and creative freedom for large-scale installations.

- Sustainable Materials and Energy Efficiency: Emphasis on eco-friendly, UV-resistant materials and higher luminous efficacy (lumens per watt) continues to drive innovation, reducing environmental impact and operational costs.

- Customization and Bespoke Solutions: Clients increasingly demand custom lengths, specific color temperatures (CCT), unique profiles, and pre-assembled kits, requiring led neon rope light outdoor manufacturers to offer extensive customization capabilities.

Key Technical Parameters for Outdoor LED Neon Rope Lights

When evaluating products from led neon rope light outdoor companies, several technical specifications are paramount:

- Material Composition: High-grade silicone or UV-stabilized PVC are the most common choices for their flexibility, durability, and resistance to environmental degradation. Silicone generally offers superior flexibility and UV stability.

- LED Type and Density: Typically SMD (Surface Mount Device) LEDs like 2835 or 5050 chips are used, with higher densities (e.g., 120 LEDs/meter) ensuring a more uniform, dot-free illumination.

- Lumen Output: Measures the total light emitted, critical for determining brightness. Outdoor applications often require higher lumen output to compete with ambient light.

- Color Temperature (CCT) & CRI: CCT (Correlated Color Temperature) is measured in Kelvin (K) and describes the color appearance of white light (e.g., 2700K warm white, 6500K cool white). CRI (Color Rendering Index) measures how accurately colors are rendered under the light source, with a CRI of 80+ being standard for quality illumination.

- Voltage (V) & Power Consumption (W/m): Common voltages include 12V, 24V (low voltage for safety and flexibility) or 120V/240V (line voltage for longer runs without voltage drop). Power consumption dictates energy efficiency.

- IP Rating: Ingress Protection rating (e.g., IP67, IP68) indicates resistance to dust and water. IP67 protects against temporary immersion, while IP68 offers continuous immersion protection.

- Bending Radius: The minimum radius to which the light can be bent without damaging the internal components or affecting performance. Critical for complex shapes and installations.

- Lifespan: Often quoted as L70, indicating the hours of operation until the light output degrades to 70% of its initial value, typically 50,000 hours or more for high-quality LEDs.

The Manufacturing Excellence of Leading LED Neon Rope Light Suppliers

Detailed Manufacturing Process of Outdoor LED Neon Rope Lights

The production of high-quality outdoor LED neon rope lights by proficient led neon rope light outdoor companies involves a multi-stage, precision-driven manufacturing process, ensuring durability, performance, and aesthetic appeal. Unlike traditional industrial components that might involve casting or forging, LED neon light manufacturing relies heavily on advanced electronics assembly and polymer extrusion.

- LED Chip Selection & Binning: The process begins with selecting high-efficiency SMD (Surface Mounted Device) LED chips, typically 2835, 3528, or 5050 types. Crucially, these chips undergo a 'binning' process. Binning sorts LEDs by subtle variations in brightness (lumen output) and color temperature (CCT) to ensure uniform light output and consistent color across large batches, preventing noticeable variations in the final product.

- PCB Assembly (SMT): The selected LED chips, along with resistors and other electronic components, are precisely mounted onto flexible Printed Circuit Boards (PCBs) using Surface Mount Technology (SMT). This automated process ensures accurate component placement and robust electrical connections, which are critical for long-term reliability. Advanced thermal management considerations are integrated at this stage to dissipate heat efficiently, extending LED lifespan.

- Soldering and Quality Control for PCB: After SMT, the PCBs undergo reflow soldering, where controlled heat melts the solder paste to form strong electrical and mechanical bonds. Post-soldering, thorough optical inspection and electrical testing (e.g., continuity, voltage drop, current draw) are performed on each PCB strip to identify any defects or inconsistencies before proceeding.

- Extrusion of Silicone/PVC Jacket: This is a defining step for outdoor LED neon. High-grade, UV-stabilized silicone or PVC compounds are extruded into the desired profile (e.g., U-shape, flat, round). The flexible PCB strips are either co-extruded directly into the polymer or carefully inserted into the pre-formed channel. Silicone offers superior UV resistance, flexibility, and resistance to extreme temperatures, making it ideal for harsh outdoor environments. PVC is more cost-effective and rigid.

- Encapsulation/Potting: For enhanced water and dust protection (IP67/IP68), the extruded profile, now containing the LED strips, may undergo an additional encapsulation or potting process. This involves filling any internal voids with a transparent, waterproof resin, further sealing the electronics from moisture and environmental contaminants.

- End Cap Sealing and Connector Integration: Customized end caps, often made from matching silicone or durable plastic, are securely sealed onto the ends of the rope light using high-strength adhesives or specialized sealing techniques. Watertight connectors (e.g., IP67/IP68 rated) for power input are integrated, ensuring the entire system maintains its environmental protection.

- Final Electrical & Environmental Testing: Each finished LED neon rope light undergoes rigorous testing. This includes electrical tests (voltage, current, power factor), photometric tests (lumen output, CCT, CRI), and crucial environmental tests such as ingress protection (IP) testing (e.g., water spray, immersion tests), UV aging tests, and temperature cycling tests to simulate real-world outdoor conditions. Compliance with standards like UL, CE, RoHS, and ETL is verified.

- Quality Assurance & Packaging: A final visual inspection ensures aesthetic quality. Products are then precisely cut to customer-specified lengths, coiled, and packaged securely with appropriate accessories (mounting clips, power supplies) for safe transit. Robust packaging protects the product until installation.

Adherence to International Standards and Certifications

Reputable led neon rope light outdoor companies strictly adhere to international quality and safety standards. This includes:

- ISO 9001: Certification for Quality Management Systems, ensuring consistent quality and continuous improvement in manufacturing processes.

- CE Mark: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- RoHS Compliance: Restriction of Hazardous Substances Directive, ensuring products do not contain specified hazardous materials.

- UL/ETL Listing: Underwriters Laboratories (UL) and Electrical Testing Laboratories (ETL) are North American safety certifications, crucial for electrical products to be legally installed and used in the US and Canada.

- ANSI/IES Standards: Compliance with photometric testing and measurement standards defined by the American National Standards Institute (ANSI) and Illuminating Engineering Society (IES).

Applications and Strategic Advantages

Diverse Application Scenarios

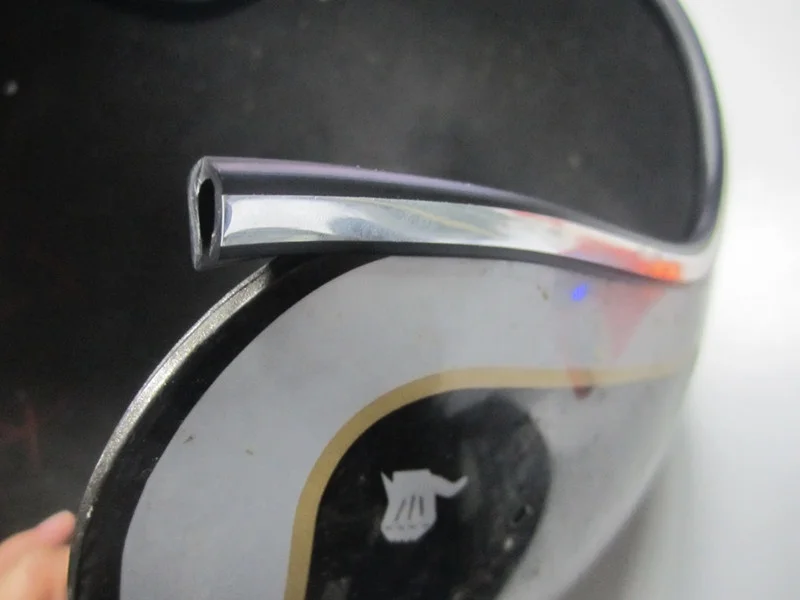

The versatility of LED neon rope lights makes them suitable for a myriad of outdoor applications, far exceeding the limited scope of industries like petrochemical or metallurgy, which often require robust products like the Flexible U shape Chrome Helmet PVC Edge Trim for protection. For LED neon, key sectors include:

- Architectural Outline Lighting: Highlighting building facades, cornices, window frames, and structural elements to create dramatic night-time visibility and aesthetic appeal.

- Commercial Signage and Branding: Replacing traditional neon in outdoor signs for businesses, restaurants, and entertainment venues, offering better durability and lower operating costs.

- Landscape and Garden Illumination: Bordering pathways, outlining garden features, illuminating sculptures, and creating ambient lighting in outdoor living spaces.

- Theme Parks and Entertainment Venues: Used for vibrant, dynamic lighting effects, wayfinding, and immersive environments in amusement parks, resorts, and event spaces.

- Bridge and Infrastructure Lighting: Enhancing the visual appeal of bridges, tunnels, and public infrastructure with long-lasting, weather-resistant linear lighting.

- Residential Outdoor Decor: Adding a touch of modern elegance to patios, decks, pool areas, and home exteriors.

Technical Advantages over Traditional Neon

Compared to legacy glass neon, modern LED alternatives from professional led neon rope light outdoor companies offer compelling advantages:

- Energy Efficiency: LED neon consumes up to 80% less energy than traditional neon, leading to significant cost savings on electricity bills.

- Durability and Safety: Being solid-state lighting encased in flexible, shatterproof materials (silicone/PVC), they are highly resistant to impact, vibration, and extreme weather, unlike fragile glass tubes. They operate at low voltage, minimizing electrical hazards.

- Long Lifespan: With a typical lifespan of 50,000 hours or more, LED neon drastically reduces maintenance and replacement costs. Traditional neon tubes typically last around 10,000-15,000 hours.

- Ease of Installation: Flexible, cuttable, and lightweight, LED neon is far simpler and quicker to install. It often requires less complex wiring and specialized mounting, making it a preferred choice for contractors and installers.

- Consistent Brightness and Color: Advanced manufacturing processes ensure consistent light output and color temperature along the entire length of the rope light, eliminating the 'hot spots' or dimming often seen in cheaper alternatives.

- Environmental Friendliness: Free from mercury and lead, LED neon is a more sustainable lighting solution, aligning with global environmental regulations and corporate responsibility initiatives.

Vendor Comparison and Customization Solutions

Choosing the Right LED Neon Rope Light Outdoor Supplier

When selecting from numerous led neon rope light outdoor exporters, it's crucial to evaluate several factors beyond just price. A truly reliable led neon rope light outdoor company will demonstrate:

- R&D and Innovation: A strong commitment to research and development, evidenced by new product releases, patented technologies, and adaptation to market demands.

- Vertical Integration: Companies that control more stages of the manufacturing process (from chip sourcing to extrusion) often offer better quality control and faster lead times.

- Global Presence and Support: The ability to serve international clients, understanding diverse market requirements and offering multilingual technical support.

- Project Management Capabilities: Experience in handling large-scale, complex projects from concept to completion, including design assistance and post-installation support.

- Sustainability Practices: A commitment to environmentally responsible manufacturing and product lifecycle.

Customization Capabilities and Bespoke Solutions

For unique architectural projects or branding initiatives, standard off-the-shelf LED neon might not suffice. Leading led neon rope light outdoor companies offer extensive customization options, including:

- Custom Lengths and Cutting Marks: Providing precise lengths and pre-marked cutting points for easy on-site adjustment without compromising IP integrity.

- Specific CCT, RGB, RGBW, or Tunable White: Tailoring color output to meet specific design requirements, from warm ambient glows to vibrant dynamic effects.

- Unique Profiles and Sizes: Manufacturing custom cross-sectional shapes (e.g., dome, flat, square) or smaller/larger diameters to fit intricate designs.

- Bending Directions (Top/Side/Multi-directional): Offering products designed to bend specifically along one axis (top-bend, side-bend) or multi-directional flexibility for complex shapes.

- Pre-assembled Kits with Connectors and Drivers: Providing plug-and-play solutions tailored to project specifications, minimizing on-site assembly.

- Custom Mounting Solutions: Designing bespoke mounting clips, channels, or aluminum profiles to seamlessly integrate the light into architectural features.

This level of flexibility ensures that designers and architects can realize their most ambitious visions with confidence, knowing they have a reliable led neon rope light outdoor supplier providing tailored solutions.

Comparative Analysis: Key Parameters of Outdoor LED Neon Rope Lights

To provide a comprehensive overview, the following table compares typical parameters offered by various led neon rope light outdoor companies. These values are representative and can vary significantly based on specific product lines and technological advancements. This data helps in making informed decisions about the ideal led neon rope light outdoor product for specific project requirements.

| Parameter | Typical Range (Standard Product) | High-Performance Options | Notes / Benefits |

|---|---|---|---|

| Material | UV-stabilized PVC | High-grade Silicone | Silicone offers superior flexibility, extreme temp resistance, and UV stability. |

| Voltage | 12V DC, 24V DC | 12V DC, 24V DC, 120V AC, 240V AC | Low voltage for safety/flexibility; Line voltage for longer runs without drop. |

| Power (W/m) | 6 - 10 W/meter | 8 - 15 W/meter (or higher for bright applications) | Determines brightness and energy consumption. |

| Lumen Output (lm/m) | 200 - 400 lm/meter | 350 - 600 lm/meter (and higher for specific models) | Higher for main illumination, lower for accent. |

| IP Rating | IP65 (Splash-proof) | IP67 (Temporary immersion), IP68 (Continuous immersion) | Critical for outdoor and submerged applications. |

| CCT Range | 2700K - 6500K (Fixed) | 2200K - 10000K, RGB, RGBW, Tunable White | Offers flexibility for desired ambiance and color dynamics. |

| CRI | >80 Ra | >90 Ra | Higher CRI means more accurate color rendering. |

| Bending Radius | >50mm (2 inches) | >20mm (0.8 inches) for some models | Allows for tighter curves and complex designs. |

| Lifespan (L70) | 50,000 hours | >70,000 hours | Reduced maintenance and replacement frequency. |

| Operating Temp. | -20°C to +45°C | -40°C to +60°C | Ensures reliability in extreme climates. |

Real-World Impact: Case Studies and Success Stories

Transformative Applications by Leading LED Neon Rope Light Outdoor Companies

The practical impact of advanced LED neon rope lights is best illustrated through successful applications, highlighting the expertise and reliability of a dedicated led neon rope light outdoor company.

Case Study 1: Iconic Hotel Facade Illumination

A prominent luxury hotel in a bustling metropolis sought to revitalize its evening presence with a dynamic, low-maintenance lighting solution. A leading led neon rope light outdoor supplier provided a custom RGBW silicone LED neon system, carefully integrated along the building's architectural lines. The system's IP68 rating ensured long-term durability against rain and humidity, while the DMX control allowed for sophisticated, synchronized light shows. The client reported a 45% reduction in energy consumption compared to their previous system and received overwhelmingly positive feedback on the hotel's enhanced visual appeal, which significantly boosted brand recognition and curb appeal. The flexibility of the silicone material allowed for precise contouring around intricate design elements that traditional neon could never achieve.

Case Study 2: Public Park Pathway Enhancement

A municipal project aimed to improve safety and aesthetics in a large urban park by outlining pedestrian pathways and seating areas. The challenge was to find a robust lighting solution that could withstand public use, vandalism attempts, and diverse weather conditions. A trusted led neon rope light outdoor company supplied a series of high-durability, anti-UV PVC LED neon ropes with an IP67 rating. These were seamlessly integrated into the landscape, providing consistent, soft illumination that enhanced navigation and created a welcoming ambiance. The low voltage operation ensured public safety, while the extended lifespan drastically reduced the city's maintenance budget. The products also benefited from a resilient external coating, similar to properties sought in a high-quality window seal strip adhesive product, providing an additional layer of protection against environmental elements and wear.

Case Study 3: Retail Chain Signage Upgrade

A national retail chain decided to upgrade its outdoor storefront signage across hundreds of locations to achieve a uniform, modern look while cutting operational costs. Collaborating with an experienced led neon rope light outdoor company, they implemented a standard white LED neon solution for outlining their brand logos and window displays. The ease of installation, consistent color temperature, and instant-on capabilities were critical for rapid deployment across multiple sites. The chain projected annual energy savings of over $150,000 across its portfolio, validating the long-term cost-effectiveness and superior performance of LED neon over traditional fluorescent or glass neon signs. The project showcased the ability of proficient led neon rope light outdoor manufacturers to deliver consistent quality and performance at scale.

Ensuring Trustworthiness: Support, Warranty, and FAQ

Commitment to Customer Support and Quality Assurance

A truly reliable led neon rope light outdoor company differentiates itself not just through product quality but also through its unwavering commitment to customer satisfaction and support. This includes:

- Comprehensive Warranty: Reputable manufacturers offer robust warranties, typically ranging from 3 to 5 years, against manufacturing defects and premature failure, reflecting confidence in their product's durability.

- Dedicated Technical Support: Access to experienced technical teams for pre-sales consultation, installation guidance, troubleshooting, and post-sales support. This might include dedicated account managers for large B2B clients.

- Efficient Delivery Cycle: Clear communication on lead times, manufacturing schedules, and logistics, ensuring timely delivery for project deadlines. For custom orders, a detailed production schedule with milestones is often provided.

- Rigorous Testing and Quality Control: Beyond initial manufacturing tests, many led neon rope light outdoor exporters perform batch testing and random sampling to ensure ongoing product consistency and compliance with declared specifications.

- Adherence to Service Level Agreements (SLAs): For major projects, a formal SLA can outline response times, support availability, and resolution procedures, offering peace of mind to clients.

Frequently Asked Questions (FAQ) for Outdoor LED Neon Rope Lights

Q1: Can outdoor LED neon rope lights be cut to custom lengths?

A1: Yes, most LED neon rope lights have designated cutting marks, typically every 0.5 or 1 meter, allowing for precise length customization. It is crucial to cut only at these marked points to maintain functionality and ingress protection. Professional sealing of the cut ends with appropriate end caps and adhesives (similar to how a window seal strip adhesive product ensures a watertight seal) is necessary to preserve the IP rating.

Q2: What power supply do I need for outdoor LED neon?

A2: This depends on the voltage of the LED neon (e.g., 12V DC, 24V DC, 120V AC, 240V AC) and the total length being installed. For low-voltage systems, a properly sized, waterproof LED driver (transformer) is required to convert mains voltage to the correct DC voltage. The total wattage of the LED neon (W/meter x total meters) must not exceed 80% of the driver's maximum output for safety and longevity.

Q3: How do I install outdoor LED neon rope lights?

A3: Installation typically involves using mounting clips, aluminum channels, or specialized mounting profiles. The method depends on the surface and desired aesthetic. Always ensure the mounting surface is clean and dry. For optimal performance and durability, follow the manufacturer's specific installation guidelines and adhere to minimum bending radii. Many led neon rope light outdoor companies provide detailed installation manuals and even video tutorials.

Q4: What is the lifespan of outdoor LED neon rope lights?

A4: High-quality outdoor LED neon rope lights from reputable led neon rope light outdoor manufacturers typically have a lifespan of 50,000 to 70,000 hours (L70 rating). This means they will maintain at least 70% of their initial brightness for that duration. Proper installation, adequate ventilation, and choosing products with appropriate IP ratings for the environment can significantly extend their operational life.

Q5: Are LED neon rope lights dimmable or color-changing?

A5: Yes, many models offer dimming capabilities (often with compatible dimmable drivers) and RGB/RGBW color-changing options, controlled via DMX, DALI, or proprietary control systems. This allows for dynamic lighting effects, scene setting, and tailored ambiance. It is important to ensure that all components (LED neon, driver, controller) are compatible for the desired functionality.

Conclusion: Partnering with Leading LED Neon Rope Light Outdoor Companies

The landscape of outdoor illumination has been irrevocably transformed by the advancements in LED neon technology. For architects, designers, commercial developers, and property managers, selecting the right led neon rope light outdoor company is paramount to the success and longevity of their lighting projects. The ideal partner will not only offer products with superior technical specifications, manufacturing precision, and adherence to international standards but also provide comprehensive support, robust warranties, and the flexibility for bespoke solutions.

By prioritizing suppliers who demonstrate deep expertise, proven experience, undeniable authoritativeness through certifications and partnerships, and a transparent commitment to trustworthiness, businesses can ensure their outdoor lighting installations are not just visually stunning but also sustainable, energy-efficient, and engineered for enduring performance in the most demanding environments. The future of outdoor linear lighting is bright, flexible, and unequivocally LED neon.

Beyond illumination, companies like Pulongte also demonstrate versatility in manufacturing capabilities, extending to crucial protective solutions such as the Flexible U shape Chrome Helmet PVC Edge Trim, which can be vital for safeguarding exposed edges in various installations, including those adjacent to outdoor lighting fixtures. This highlights a broader expertise in durable polymer extrusion and protective applications, underscoring the comprehensive solutions a specialized window seal strip adhesive supplier or manufacturer can offer to various industrial and commercial needs.

References

- Illuminating Engineering Society (IES). (2020). The Lighting Handbook, 11th Edition. IES.

- National Electrical Code (NFPA 70). (2023). National Fire Protection Association.

- International Electrotechnical Commission (IEC). (2019). IEC 60598-1: Luminaires – Part 1: General requirements and tests.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems – Requirements.

- U.S. Department of Energy (DOE). (2022). Solid-State Lighting R&D Plan.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025