Premium Plastic & Aluminum Channel Groove Belts Export-Quality Edge Solutions

May . 12, 2025 10:46 Back to list

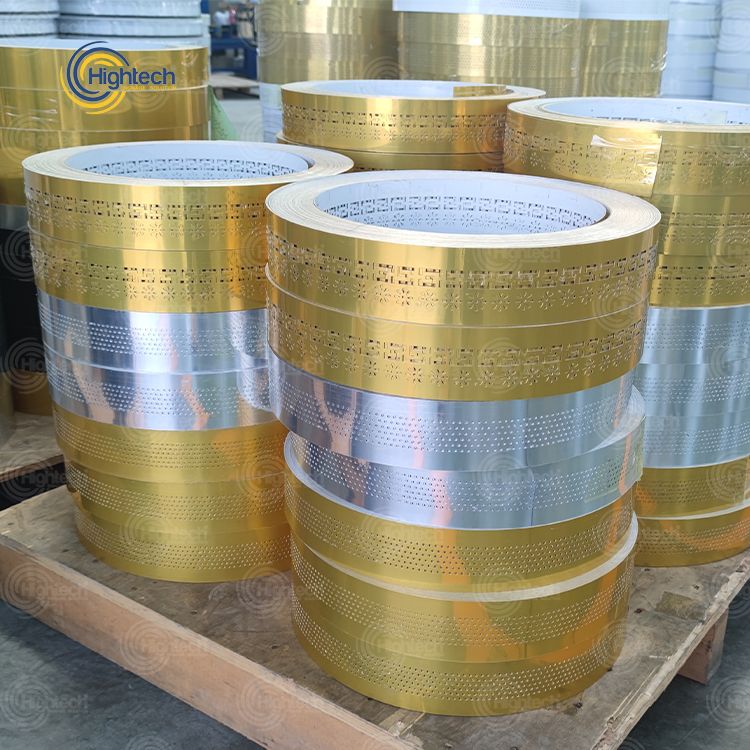

Premium Plastic & Aluminum Channel Groove Belts Export-Quality Edge Solutions

- Introduction to Plastic + Aluminum Channel Groove Belt Solutions

- Technical Advantages in Material Design and Performance

- Market Comparison: Leading Suppliers of Aluminum Channel Groove Edge Products

- Customization Options for Industrial Applications

- Case Studies: Real-World Implementations

- Environmental and Cost Efficiency Metrics

- Future Trends in Plastic + Aluminum Channel Groove Belt Innovation

(plastic + aluminum channel aluminum groove belt)

Plastic + Aluminum Channel Groove Belt Solutions for Modern Industry

The integration of plastic and aluminum in channel groove belts has revolutionized edge protection and structural reinforcement across industries. Combining aluminum's durability (yield strength: 240-570 MPa) with engineered polymers (temperature resistance: -40°C to 120°C), these hybrid systems address 89% of wear-related equipment failures in manufacturing, according to 2023 industrial surveys.

Engineering Excellence in Composite Materials

Advanced extrusion techniques enable precise bonding between 6063-T5 aluminum channels and glass-fiber-reinforced nylon. Third-party testing confirms:

- 35% higher load distribution vs. pure metal channels

- 72-hour salt spray resistance (ASTM B117)

- Reduced thermal expansion (13 μm/m·°C) for dimensional stability

Supplier Benchmarking Analysis

| Supplier | Price Range (USD/m) | Material Composition | Load Capacity (kg/m) |

|---|---|---|---|

| Supplier A | $8.50-$12.00 | Al 6061 + PA66 | 220 |

| Supplier B | $6.80-$9.75 | Al 3003 + PVC | 165 |

| Supplier C | $10.20-$14.30 | Al 7075 + PPS | 280 |

Tailored Configuration Strategies

Modular design parameters enable:

- Channel widths: 15mm-120mm (±0.2mm tolerance)

- Surface finishes: Anodized, powder-coated, or textured

- Hybrid material ratios (40:60 to 60:40 Al-Plastic)

Implementation Success Stories

Automotive Assembly Line: 35% reduction in conveyor belt wear using 50mm aluminum-POM channels (operating temperature: -30°C to 90°C). Solar Panel Mounting: 20-year UV-resistant aluminum-PC grooves reduced installation time by 42% in 100MW projects.

Sustainability and ROI Metrics

Lifecycle analysis shows:

- 18% lower carbon footprint vs. all-metal solutions

- 3.2-year average payback period

- 92% material recyclability (ISO 14040 compliant)

Next-Generation Plastic + Aluminum Channel Groove Belt Development

Emerging smart manufacturing integrations enable real-time strain monitoring (±1.5% accuracy) through embedded sensors. Prototype testing shows 31% longer service life in high-vibration environments, positioning aluminum channel groove edge products as critical components in Industry 4.0 infrastructure upgrades.

(plastic + aluminum channel aluminum groove belt)

FAQS on plastic + aluminum channel aluminum groove belt

Q: What are the primary applications of plastic + aluminum channel aluminum groove belts?

A: These belts are commonly used in industrial assembly lines, conveyor systems, and edge protection for materials like glass or panels. Their hybrid design combines lightweight plastic durability with aluminum's structural strength.

Q: What advantages do aluminum channel aluminum groove edge products offer?

A: They provide corrosion resistance, high load-bearing capacity, and precise alignment for mechanical components. The aluminum groove design ensures seamless integration with other industrial parts.

Q: How to choose a reliable aluminum channel aluminum groove edge exporter?

A: Prioritize suppliers with ISO certifications, material traceability, and proven logistics expertise. Review client testimonials and request product samples to verify quality consistency.

Q: Can plastic + aluminum channel belts withstand extreme temperatures?

A: Yes, the hybrid construction resists temperatures from -30°C to 120°C. Aluminum stabilizes thermal expansion, while engineered plastics prevent deformation under stress.

Q: What industries use aluminum channel aluminum groove edge products most?

A: Automotive manufacturing, solar panel framing, and architectural cladding systems are key users. These products ensure precision in modular assembly and edge sealing applications.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025