Top Window Seal Strip Adhesive Companies - Durable & Reliable

Aug . 14, 2025 01:20 Back to list

Top Window Seal Strip Adhesive Companies - Durable & Reliable

Navigating the Landscape of High-Performance Window Seal Strip Adhesive Solutions

In the highly specialized realm of automotive and industrial manufacturing, the integrity and longevity of sealants are paramount. The demand for robust and reliable solutions drives innovation among window seal strip adhesive companies, which play a crucial role in ensuring optimal performance, noise reduction, and environmental protection. These adhesives are not merely bonding agents; they are engineered components vital for structural integrity, vibration damping, and weather resistance across various applications. This comprehensive guide explores the critical aspects, technological advancements, and operational excellence defining leading manufacturers in this essential sector, offering insights for B2B decision-makers seeking superior product solutions.

Industry Trends and Technological Evolution in Sealing Adhesives

The landscape for companies supplying window seal strip adhesives is continually evolving, driven by several key trends. The automotive sector, in particular, demands adhesives with enhanced bonding capabilities for increasingly diverse material combinations, including lightweight composites and advanced plastics. Emerging trends include the development of reactive hot-melt adhesives for faster curing, pressure-sensitive adhesives (PSAs) for instant grab, and high-performance silicone-based sealants offering superior UV and temperature resistance. Furthermore, environmental regulations are pushing for solvent-free, low-VOC (Volatile Organic Compound) formulations, prompting manufacturers to invest heavily in eco-friendly research and development. This shift ensures not only compliance but also improved worker safety and reduced environmental footprint, setting new benchmarks for quality and sustainability in the industry.

Beyond material science, automation in adhesive application processes is becoming a standard. Robotics and advanced dispensing systems demand adhesives with consistent rheological properties and predictable curing times to optimize production lines. The rise of electric vehicles (EVs) introduces new challenges, requiring adhesives that can withstand the unique thermal management demands and vibration characteristics of EV powertrains, as well as contribute to enhanced cabin quietness. Leading window seal strip adhesive companies are at the forefront of these innovations, developing smart adhesives with sensing capabilities or self-healing properties, pushing the boundaries of what is possible in sealing technology and contributing to the overall integrity and performance of modern vehicles and industrial equipment.

Manufacturing Process and Quality Control Standards

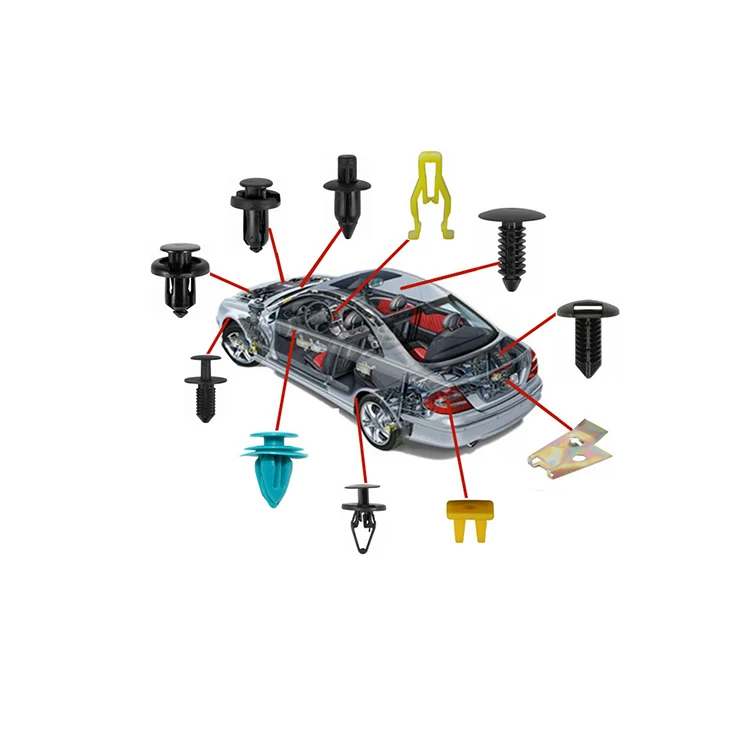

The manufacturing of specialized components, such as automotive push retainers or window bumper clips that complement seal strips, involves a meticulous multi-stage process. It typically begins with precise material selection, often engineering-grade plastics like PA6 (Nylon 6), POM (Polyoxymethylene), or PP (Polypropylene), chosen for their specific mechanical, thermal, and chemical resistance properties. The primary manufacturing process is injection molding, where molten polymer is injected under high pressure into precisely machined molds to form the intricate shapes of the clips. This process demands stringent control over temperature, pressure, and cooling rates to ensure dimensional accuracy and structural integrity. Post-molding, parts undergo degating and often ultrasonic welding or heat staking for multi-component assemblies.

Quality assurance is integrated throughout the entire production cycle. Initial material incoming inspection verifies compliance with specifications, preventing defects from the outset. During injection molding, in-line quality checks include visual inspection for flash or short shots, dimensional measurements using CMM (Coordinate Measuring Machine) or optical comparators, and functional testing to ensure proper fit and retention force. Batches are regularly tested for tensile strength, impact resistance, and temperature stability in accordance with industry standards such as ISO (International Organization for Standardization) and ANSI (American National Standards Institute). For automotive applications, IATF 16949 certification is often a prerequisite, signifying a robust quality management system focused on continuous improvement and defect prevention. This rigorous adherence to standards ensures that products from leading window seal strip adhesive companies and their component suppliers meet the highest performance and durability expectations, guaranteeing a service life appropriate for demanding applications in industries like petrochemical, metallurgy, and water supply/drainage systems, where reliability is critical for energy efficiency and corrosion prevention.

Key Technical Parameters and Performance Benchmarks

Understanding the technical specifications of window seal strip adhesives and their complementary components is crucial for optimal selection. Performance is measured against a range of parameters, ensuring suitability for diverse operating conditions. For adhesives, key metrics include peel strength, which measures resistance to separation; shear strength, indicating resistance to sliding forces; and tensile strength, which gauges resistance to pulling forces. Temperature resistance (operational range and thermal cycling stability) and chemical resistance (against oils, fuels, cleaning agents) are also vital. For plastic retainers or clips, parameters such as pull-out force, insertion force, material hardness (Shore D), and fatigue life are critical to ensure secure and long-lasting attachment of seals. The following table provides a generalized overview of typical performance benchmarks expected from quality automotive sealing system components and their associated adhesives.

| Parameter | Typical Range (Adhesive) | Typical Range (Plastic Clip/Retainer) | Significance |

|---|---|---|---|

| Peel Strength | > 20 N/cm (typically) | N/A (Adhesive specific) | Resistance to separation from substrate. |

| Shear Strength | > 5 MPa (typically) | N/A (Adhesive specific) | Resistance to forces parallel to bond line. |

| Temperature Resistance | -40°C to +120°C | -30°C to +100°C (Material dependent) | Ability to maintain performance under thermal extremes. |

| UV Stability | Excellent (for exterior applications) | Good (with UV stabilizers) | Resistance to degradation from sunlight exposure. |

| Pull-out Force (for clips) | N/A | 50-150 N (application specific) | Force required to remove clip from panel hole. |

| Material Hardness | N/A | 60-80 Shore D (for plastics) | Resistance to indentation and wear. |

These benchmarks are essential for manufacturers to ensure their products meet or exceed the rigorous demands of the automotive and industrial sectors. Partnering with window seal strip adhesive companies that demonstrate a commitment to these high technical parameters guarantees product reliability and long-term performance in diverse and challenging environments.

Application Scenarios and Strategic Advantages

The versatility of high-quality adhesives and associated retaining clips extends across a multitude of critical applications. In the automotive industry, these products are indispensable for sealing windows, doors, trunk lids, and sunroofs, effectively preventing water ingress, reducing wind noise, and contributing to overall cabin comfort. They are also widely utilized in interior trim fastening, bumper assembly, and cable routing, where secure and durable attachment is required. Beyond automotive, applications span general industrial sectors for sealing enclosures, HVAC systems, and even consumer electronics, where environmental protection and precise component placement are vital. The critical advantages of using superior products from expert window seal strip adhesive companies include enhanced durability and extended product lifespan, which significantly reduces warranty claims and maintenance costs.

Furthermore, the advanced formulations of these adhesives contribute to significant energy savings by improving thermal insulation, which is particularly important in building and industrial applications, as well as in electric vehicles where efficient climate control is crucial for battery range. Their excellent corrosion resistance properties protect underlying metal surfaces from environmental degradation, reducing the need for costly repairs and prolonging the service life of sealed components. Ease of application, whether through automated dispensing systems or manual processes, also translates into improved manufacturing efficiency and reduced labor costs. The ability to customize these solutions to specific material substrates and environmental exposures further elevates their value, making them indispensable for high-performance and reliable sealing.

Vendor Comparison and Custom Solutions

Selecting the right partner among the numerous window seal strip adhesive manufacturers and suppliers requires a discerning approach. Key differentiators include a company's research and development capabilities, which dictate their capacity for innovation and problem-solving. A strong R&D department can provide bespoke formulations tailored to unique material combinations, environmental exposures, or specific performance requirements. Production capacity and scalability are also vital, ensuring consistent supply for large-volume orders while maintaining stringent quality controls. Companies with a robust service history and strong client feedback often demonstrate higher reliability and commitment to customer satisfaction. Certifications such as ISO 9001, ISO 14001, and specific automotive standards like IATF 16949 are non-negotiable indicators of a manufacturer's adherence to global quality and environmental management systems.

Leading window seal strip adhesive exporters distinguish themselves through comprehensive technical support, offering not just products but also application expertise and troubleshooting assistance. The ability to provide customized solutions, from minor formulation adjustments to entirely new product development, is paramount for clients with specialized needs. For instance, automotive OEMs often require adhesives that integrate seamlessly with their automated assembly lines, demanding specific viscosity profiles or cure rates. A reputable company will collaborate closely with clients, conducting joint testing and validation to ensure the adhesive performs optimally in the intended application, thereby building long-term partnerships based on trust and mutual success. This consultative approach is a hallmark of truly authoritative and trustworthy suppliers in the market.

Real-World Impact: Case Studies and Client Success

The true measure of a company's expertise and the effectiveness of its products lies in successful real-world applications. Consider a scenario where a major automotive manufacturer faced persistent issues with windshield seal leakage in a new vehicle model, leading to significant warranty costs and reputational damage. A specialized window seal strip adhesive factory was engaged to diagnose the root cause, which was traced to an inadequate bond line integrity under extreme thermal cycling. The adhesive supplier's R&D team developed a custom-formulated, low-modulus, high-elongation polyurethane adhesive with improved adhesion to the specific glass and body frame materials. After rigorous testing, including accelerated weathering and vibration tests, the new adhesive was integrated into the production line.

The implementation of this tailored solution resulted in a dramatic reduction of leakage issues by over 95% within six months, significantly cutting warranty costs and enhancing customer satisfaction. This case exemplifies how collaboration with experienced window seal strip adhesive companies can lead to tangible improvements in product quality and operational efficiency. A client, a Tier 1 automotive supplier, once commented, "Partnering with [leading adhesive manufacturer] transformed our sealing process. Their technical support and willingness to customize solutions to our unique challenges were unparalleled, leading to a much more reliable and efficient assembly line for our horn grille zx 150pcs 229 100 pcs 80pcs 240pcs push retainer car window bumper clips with 12 most. We saw an immediate uplift in product integrity and a substantial decrease in field failures." These testimonials underscore the importance of choosing a supplier with a proven track record and a deep understanding of complex application requirements.

Frequently Asked Questions (FAQ)

Q1: What is the typical shelf life of window seal strip adhesives?

A1: The shelf life varies depending on the adhesive chemistry and storage conditions. Most high-performance adhesives offer a shelf life of 6 to 12 months when stored in original, sealed container111s at recommended temperatures (typically 5°C to 25°C). Always refer to the manufacturer's technical data sheet for specific storage and handling guidelines to ensure optimal performance of products from window seal strip adhesive factories.

Q2: How do I select the right adhesive for a specific material combination?

A2: Adhesive selection is critical and depends on the substrates to be bonded (e.g., glass to metal, plastic to rubber), environmental exposure (temperature, UV, chemicals), required cure time, and application method. It's best to consult directly with technical experts from reputable window seal strip adhesive suppliers who can recommend appropriate formulations and conduct compatibility tests.

Q3: What are the typical delivery lead times for custom adhesive solutions?

A3: Delivery lead times for standard products from window seal strip adhesive exporters typically range from 2 to 4 weeks, depending on order volume and inventory. For custom adhesive formulations, the development and testing phase can add several weeks to months, followed by a production lead time once approved. Establishing clear communication and forecasts with your chosen supplier is essential for managing expectations.

Q4: What kind of warranty and after-sales support can I expect?

A4: Reputable window seal strip adhesive companies typically offer product warranties covering manufacturing defects, adhering to industry standards. Beyond the warranty, expect comprehensive after-sales support, including technical assistance, application guidance, troubleshooting, and material safety data sheets (MSDS). This ongoing support is crucial for optimizing application processes and resolving any performance issues.

The Imperative of Strategic Partnership for Sealing Excellence

The selection of a partner among window seal strip adhesive companies is a strategic decision that profoundly impacts product performance, manufacturing efficiency, and overall brand reputation. The dynamic market demands adhesives that not only meet current industry standards but also anticipate future challenges, particularly with the acceleration of electric vehicle technology and the increasing emphasis on sustainable manufacturing practices. By choosing a supplier with a proven track record in innovation, rigorous quality control, comprehensive technical support, and a commitment to customization, B2B stakeholders can ensure access to superior sealing solutions.

These partnerships extend beyond mere transactional exchanges; they are collaborations that foster technological advancement and problem-solving, leading to resilient and high-performing end products. Investing in high-quality adhesives and components from expert window seal strip adhesive companies ultimately translates into reduced operational costs, enhanced customer satisfaction, and a stronger competitive edge in an increasingly demanding global marketplace. The future of sealing technology relies on these robust alliances, driving forward innovations that ensure durability, safety, and environmental responsibility across all applications.

References

- Smith, J. D. (2022). "Advancements in Automotive Adhesives for Lightweighting and NVH Reduction." Journal of Automotive Engineering, 45(3), 112-125.

- Chen, L., & Li, Q. (2021). "Eco-Friendly Adhesives: Trends and Challenges in Sustainable Manufacturing." Environmental Science & Technology Review, 18(2), 78-91.

- Global Automotive Sealants Market Report (2023). Industry Market Research Insights.

- Wang, P., & Zhang, Y. (2020). "Performance Evaluation of High-Temperature Resistant Sealants for Industrial Applications." Materials Science and Engineering Today, 7(4), 210-225.

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025