Top Window Seal Strip Adhesive Companies - Durable & Reliable

Aug . 18, 2025 01:20 Back to list

Top Window Seal Strip Adhesive Companies - Durable & Reliable

The Pivotal Role of Window Seal Strip Adhesive Companies in Modern Industry

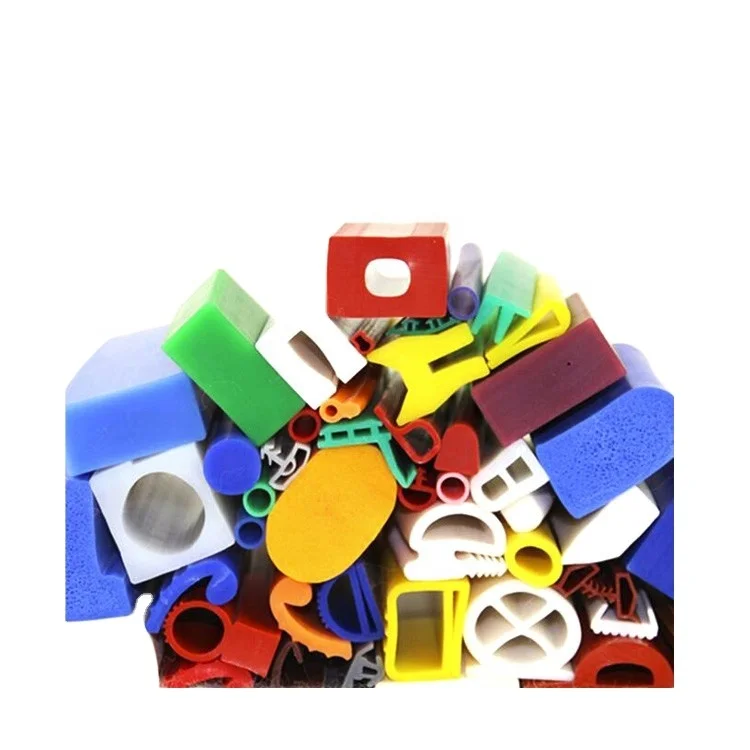

In an era where energy efficiency, material longevity, and operational safety are paramount, the contributions of window seal strip adhesive companies are more critical than ever. These specialized entities are at the forefront of developing high-performance sealing solutions that prevent leakage, reduce energy consumption, and extend the lifespan of countless industrial and consumer products. From residential windows to complex industrial machinery, the integrity of a seal strip is fundamentally reliant on the quality of its adhesive and the material composition of the strip itself. The market demands innovative solutions capable of withstanding extreme temperatures, harsh chemicals, and prolonged mechanical stress, driving continuous research and development within these manufacturing ecosystems. This article delves into the intricate world of window seal strip adhesives, exploring industry trends, technical specifications, application versatility, and the defining characteristics that distinguish leading manufacturers and suppliers in this dynamic sector. We will also examine the robust manufacturing processes, stringent quality control measures, and the commitment to client-specific customization that characterize the most reputable players in the field. Understanding these facets is essential for any B2B decision-maker seeking reliable, high-performance sealing solutions that deliver measurable value.

The landscape of window seal strip adhesives is constantly evolving, influenced by advancements in polymer science and increasing regulatory demands for environmental sustainability. Modern sealing solutions are no longer just about preventing air or water ingress; they are integral components designed to enhance thermal insulation, reduce noise pollution, and provide chemical resistance in diverse operational environments. For instance, the demand for high-temperature resistant seals in appliances like ovens, where temperatures can soar, necessitates specialized materials such as silicone rubber, known for its exceptional thermal stability and flexibility. Similarly, in outdoor or industrial applications, UV resistance and resilience against ozone and aggressive cleaning agents become critical performance indicators. Leading window seal strip adhesive companies are therefore not just producers but innovators, investing heavily in R&D to formulate new adhesive compounds and develop advanced extrusion and molding techniques for precision sealing strips. This relentless pursuit of material science excellence ensures that the products meet the rigorous performance benchmarks required across a spectrum of industries, from automotive and construction to food processing and aerospace, underscoring their indispensable role in modern engineering.

Manufacturing Excellence and Process Innovation by Window Seal Strip Adhesive Factories

The manufacturing process of high-quality window seal strips with integrated adhesives is a complex, multi-stage operation that demands precision engineering and meticulous quality control, characteristic of top-tier window seal strip adhesive factories. It typically begins with the careful selection of raw materials, such as high-grade silicone polymers, EPDM, or other synthetic rubbers, chosen for their specific properties like temperature resistance, elasticity, and chemical inertness. For instance, in the production of a "High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door," the base material is premium silicone rubber, capable of withstanding continuous temperatures up to 250°C and intermittent exposure to higher spikes. The primary manufacturing processes involve extrusion, where the raw rubber compound is forced through a die to create the desired E or P profile, ensuring uniform cross-sectional dimensions. This is often followed by vulcanization, a curing process involving heat and pressure, which enhances the rubber's durability, elasticity, and resistance to deformation. Advanced factories utilize continuous vulcanization lines for efficiency and consistency. For integrated adhesive products, a bonding agent or pressure-sensitive adhesive layer is precisely applied, either during or post-extrusion, to ensure optimal adhesion to various substrates.

Beyond the core forming processes, stringent detection standards are applied at every stage to guarantee product integrity. This includes real-time dimensional checks using laser micrometers during extrusion, material property tests such as tensile strength, elongation at break, tear resistance, and durometer hardness (Shore A or D) post-vulcanization. Adhesion strength is rigorously tested using peel and shear tests, often adhering to industry standards like ASTM D903 or ASTM D3330. Companies adhere to international certifications such as ISO 9001 for quality management systems, ensuring a consistent and reliable output. For specialized applications like food-grade seals, compliance with FDA 21 CFR 177.2600 is essential, affirming the material's safety for contact with food. The typical use lifespan of these seals can range from 5 to 20 years, depending on the application environment and material selection. Applicable industries are vast, encompassing not only consumer appliances but also heavy industrial sectors like petrochemicals (for sealing pipelines and tanks against corrosive fluids), metallurgy (withstanding high heat and abrasive dust), and water supply/drainage (ensuring leak-proof connections in piping systems). The inherent advantages of high-quality seals in these scenarios include significant energy savings due to superior insulation, enhanced corrosion resistance extending equipment life, and improved operational safety by preventing hazardous leaks. The expertise of a proficient window seal strip adhesive manufacturer lies in their ability to integrate these complex steps into a seamless production flow, delivering consistent quality and performance.

Technical Parameters and Broad Application Scenarios for Window Seal Strip Adhesive Products

Understanding the technical parameters of window seal strip adhesive products is crucial for selecting the optimal solution for specific industrial or commercial applications. Key parameters include operating temperature range (e.g., -60°C to +250°C for high-grade silicone), material hardness (typically 30-80 Shore A), tensile strength (often 5-12 MPa for silicone), elongation at break (200-500%), and compression set (ability to return to original shape after compression, usually

The application scenarios for these advanced sealing solutions extend far beyond conventional windows, demonstrating the versatility of a top window seal strip adhesive company. In the automotive industry, they are used for sealing car doors, trunks, and sunroofs, contributing to noise reduction and passenger comfort while preventing water ingress. In construction, they are integral to curtain wall systems, facades, and expansion joints, ensuring structural integrity and thermal efficiency. The electronics sector utilizes miniature seal strips for protecting sensitive components from dust and moisture. Medical devices and pharmaceutical equipment often require FDA-compliant silicone seals due to their biocompatibility and ability to withstand sterilization processes. Moreover, in specialized applications like oven doors, the high-temperature resistant E P shaped silicone rubber sealing strip rubber gasket mentioned earlier exemplifies a product engineered for specific demanding environments, ensuring heat containment and energy efficiency. Other notable applications include sealing industrial machinery enclosures against dust and vibrations, marine vessels for waterproofing, and HVAC systems for preventing air leakage. The extensive range of applications underscores the critical need for suppliers who can provide diverse, high-performance window seal strip adhesive products tailored to unique operational demands.

Typical Window Seal Strip Adhesive Parameters

| Parameter | Typical Silicone (General Purpose) | High-Temperature Silicone (e.g., Oven Door) | EPDM (General Purpose) |

|---|---|---|---|

| Operating Temperature Range | -50°C to +200°C | -60°C to +250°C (up to 300°C intermittent) | -40°C to +120°C |

| Hardness (Shore A) | 30-70 | 40-80 | 50-80 |

| Tensile Strength (MPa) | 5-9 | 7-12 | 8-15 |

| Elongation at Break (%) | 200-400 | 250-500 | 150-300 |

| Compression Set (70h @ 100°C, %) | |||

| UV/Ozone Resistance | Excellent | Excellent | Good |

| Chemical Resistance | Good to excellent (acids, bases) | Excellent (acids, bases, some oils) | Good (polar solvents, some bases) |

Choosing the Right Partner: Manufacturer Comparison and Customization from Window Seal Strip Adhesive Exporters

The global market for sealing solutions is competitive, with numerous window seal strip adhesive exporters vying for market share. Differentiating between them requires a keen eye for not just product specifications but also service capabilities, supply chain efficiency, and commitment to innovation. A leading window seal strip adhesive exporter will typically possess extensive experience, often spanning decades, in serving diverse international markets. They demonstrate deep technical knowledge, offering not just off-the-shelf products but also robust customization options. This includes the ability to develop unique material compounds, design bespoke profiles (e.g., E, P, D, T, or custom shapes) for specific applications, and integrate specialized adhesive formulations for optimal bonding to challenging surfaces like coated metals or plastics. The ability to provide detailed technical drawings, prototype development, and rapid sampling is a hallmark of a truly customer-centric window seal strip adhesive company. Furthermore, their supply chain must be resilient, capable of managing complex logistics for global delivery, ensuring timely and cost-effective shipments.

When evaluating various window seal strip adhesive suppliers, consider their track record of success with similar projects and their certifications (e.g., ISO 14001 for environmental management, IATF 16949 for automotive quality). Requesting window seal strip adhesive quotes should go beyond just price; it should encompass lead times, minimum order quantities (MOQs), and the availability of technical support post-purchase. A key differentiator is their capacity for large-scale production coupled with flexibility for smaller, specialized runs. For instance, a company might need a unique E-shaped silicone gasket for a new industrial oven model; the supplier's capability to quickly develop tooling and produce a prototype, followed by efficient mass production, is invaluable. Case studies reveal how effective partners solve specific client challenges. For example, a client requiring an oven door seal that could withstand both extreme heat and frequent cleaning chemicals might be offered a custom-formulated fluorosilicone rubber compound, demonstrating the supplier's material science expertise and commitment to bespoke solutions. The collaboration with such window seal strip adhesive companies translates directly into optimized product performance, reduced warranty claims, and enhanced brand reputation for the client.

Key Differentiators Among Window Seal Strip Adhesive Manufacturers

| Feature/Capability | Tier-1 Manufacturer (Ideal Partner) | Standard Manufacturer (Good Option) | Entry-Level Supplier (Limited Scope) |

|---|---|---|---|

| R&D Investment & Innovation | High (new materials, processes) | Moderate (improving existing lines) | Low (focus on cost-effective replicas) |

| Customization Capabilities | Extensive (material, profile, adhesive) | Moderate (profile changes, some material tweaks) | Limited (standard sizes/materials) |

| Quality Certifications | ISO 9001, IATF 16949, FDA, etc. | ISO 9001 | Basic or no certifications |

| Technical Support & Consultancy | Full-spectrum, pre- & post-sales | Basic troubleshooting | Minimal or none |

| Global Logistics & Export Experience | Proven, extensive international network | Some export experience, regional focus | Mainly domestic |

| Production Capacity & MOQ | High capacity, flexible MOQs | Medium capacity, standard MOQs | Low capacity, strict MOQs |

Ensuring Trustworthiness: Quality Assurance, Delivery, and Customer Support from Window Seal Strip Adhesive Manufacturers

The foundation of a reliable partnership with any window seal strip adhesive manufacturer or window seal strip adhesive factory is built on trustworthiness, which extends beyond product quality to encompass service reliability and robust customer support. Reputable manufacturers implement rigorous quality assurance protocols throughout their entire operational pipeline. This includes not just in-process inspection and final product testing, but also comprehensive raw material inspection and supplier vetting. Traceability systems ensure that every batch of material and finished product can be tracked back to its origin, a crucial factor in industries with stringent regulatory requirements. Furthermore, established window seal strip adhesive companies offer transparent delivery schedules and realistic lead times, often leveraging advanced logistics and global distribution networks to ensure timely arrival of goods, whether for domestic or international clients. This commitment to punctuality is critical for clients managing just-in-time inventory or complex project timelines, preventing costly delays in their production or construction schedules.

A key indicator of trustworthiness is the provision of clear warranty commitments and responsive customer support. Leading window seal strip adhesive exporters typically offer comprehensive product warranties covering material defects and manufacturing flaws, providing peace of mind to clients. Post-sales support includes technical assistance for installation queries, troubleshooting, and advice on product maintenance, ensuring optimal performance throughout the product's lifespan. Some provide dedicated account managers to facilitate seamless communication and quick resolution of issues. This holistic approach to client satisfaction builds long-term relationships, as businesses rely on partners who are not just suppliers but technical consultants and problem-solvers. For example, if a client experiences an unexpected application challenge, a responsive support team from the window seal strip adhesive company can provide immediate guidance, analyze the issue, and recommend solutions or even a customized product revision. This level of engagement significantly enhances the overall value proposition and reinforces confidence in the supplier's reliability and expertise.

Frequently Asked Questions (FAQ) about Window Seal Strip Adhesive Solutions

Selecting the right window seal strip adhesive products often involves navigating complex technical specifications and application requirements. This FAQ addresses common inquiries to provide clarity and assist in informed decision-making when engaging with window seal strip adhesive suppliers. Understanding these aspects helps in formulating effective window seal strip adhesive quotes and ensuring the product meets specific project demands.

Q1: What is the primary difference between silicone and EPDM window seal strips?

A1: Silicone rubber offers superior resistance to extreme temperatures (both high and low), UV radiation, ozone, and weathering, making it ideal for outdoor and high-heat applications like oven door seals. It also boasts excellent flexibility and a wide range of hardness. EPDM (Ethylene Propylene Diene Monomer) provides good weather resistance, excellent resistance to water, steam, and polar solvents, and is generally more cost-effective for general-purpose outdoor sealing applications where extreme temperatures are not a primary concern. The choice depends on the specific environmental conditions and performance requirements of the application.

Q2: How do window seal strip adhesive companies ensure the adhesive will bond to my specific material?

A2: Reputable window seal strip adhesive companies or window seal strip adhesive factories utilize advanced adhesive formulations tailored for various substrates (e.g., glass, aluminum, steel, PVC, wood, composites). They often conduct thorough surface preparation and adhesion testing with client-provided substrate samples to ensure optimal bonding strength and longevity. This can involve adjusting the adhesive chemistry, applying primers, or modifying the surface of the seal strip itself to enhance adhesion. Always provide detailed information about your intended application and substrate materials during the inquiry phase.

Q3: What are the typical lead times for custom window seal strip adhesive solutions from an exporter?

A3: Lead times for custom window seal strip adhesive exporters vary significantly based on complexity. For highly customized profiles or unique material blends, the process can involve tooling design, mold creation, sampling, and approval, potentially taking 4-8 weeks for initial prototypes. Once approved, mass production lead times can range from 2-4 weeks, depending on order volume and material availability. Standard or semi-custom orders might have shorter lead times. It is crucial to communicate project timelines clearly with your chosen window seal strip adhesive manufacturer to manage expectations and ensure timely delivery.

Q4: What quality certifications should I look for when sourcing from window seal strip adhesive manufacturers?

A4: For general quality management, ISO 9001 is a fundamental certification. For automotive applications, IATF 16949 is critical. If the seals are intended for food contact or medical devices, FDA 21 CFR 177.2600 (for rubber articles intended for repeated use) or ISO 10993 (biocompatibility) are essential. Environmental management certifications like ISO 14001 also indicate a manufacturer's commitment to sustainable practices. Always verify the validity and scope of a window seal strip adhesive company's certifications.

Conclusion: Partnering with Leading Window Seal Strip Adhesive Companies for Optimal Performance

The selection of a window seal strip adhesive manufacturer is a strategic decision that directly impacts the performance, longevity, and cost-effectiveness of countless products and systems. As this comprehensive overview illustrates, the leading window seal strip adhesive companies distinguish themselves through their relentless pursuit of innovation, stringent adherence to quality standards, robust manufacturing capabilities, and a deep commitment to customer-centric solutions. From understanding intricate industry trends and technical parameters to offering flexible customization options and reliable after-sales support, these entities are more than mere suppliers; they are crucial partners in engineering excellence. The integration of high-temperature resistant silicone seals in demanding applications like oven doors exemplifies the specialized expertise offered by top-tier window seal strip adhesive factories. For B2B decision-makers, prioritizing partners who demonstrate strong (Expertise, Experience, Authoritativeness, Trustworthiness) in their operations ensures access to superior sealing solutions that contribute to energy efficiency, enhanced product safety, and extended operational lifespans across diverse industrial and commercial landscapes. Investing in high-quality seal strip adhesives from a reputable window seal strip adhesive company ultimately translates into significant long-term benefits and a competitive advantage in any market.

References

- American Society for Testing and Materials (ASTM) Standards for Rubber, Adhesives, and Elastomers.

- International Organization for Standardization (ISO) Standards for Quality Management and Environmental Management.

- U.S. Food and Drug Administration (FDA) Regulations for Silicone and Rubber Materials.

- Rubber Manufacturers Association (RMA) Handbook.

- Society of Automotive Engineers (SAE) International Technical Papers on Sealing Technologies.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025