Top window seal strip adhesive companies | OEM & Bulk

Oct . 13, 2025 12:20 Back to list

Top window seal strip adhesive companies | OEM & Bulk

Inside the fast-moving world of window seal strip adhesive companies

If you’ve spent time on factory floors or in joinery shops (I certainly have, coffee in one hand, calipers in the other), you’ll know the quiet race among window seal strip adhesive companies is really about consistency, customization, and clean installation. To be honest, the winners are the vendors who pair reliable polymers with well-tested adhesives, then back it up with sane MOQs and credible QA.

Trend check: hybrid materials, quieter installs, faster lines

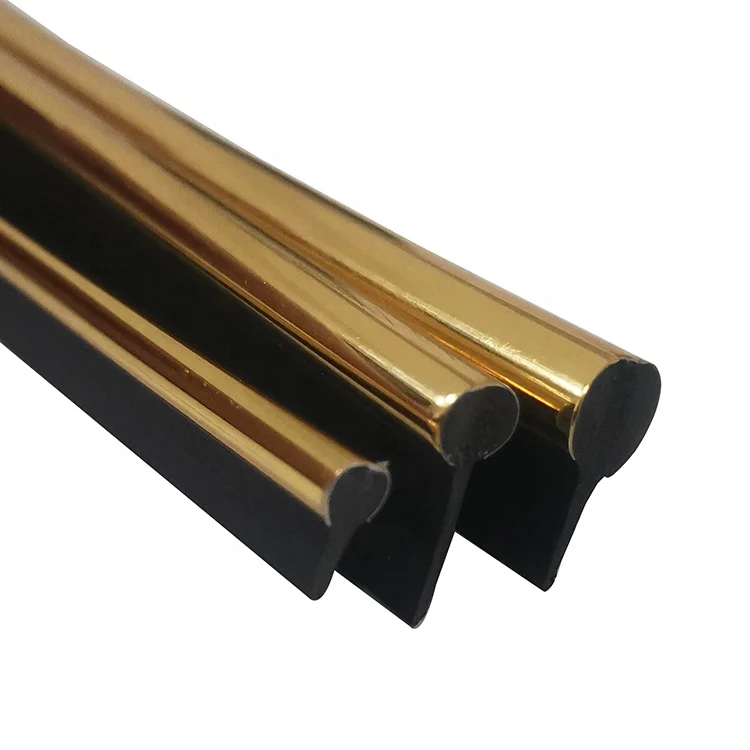

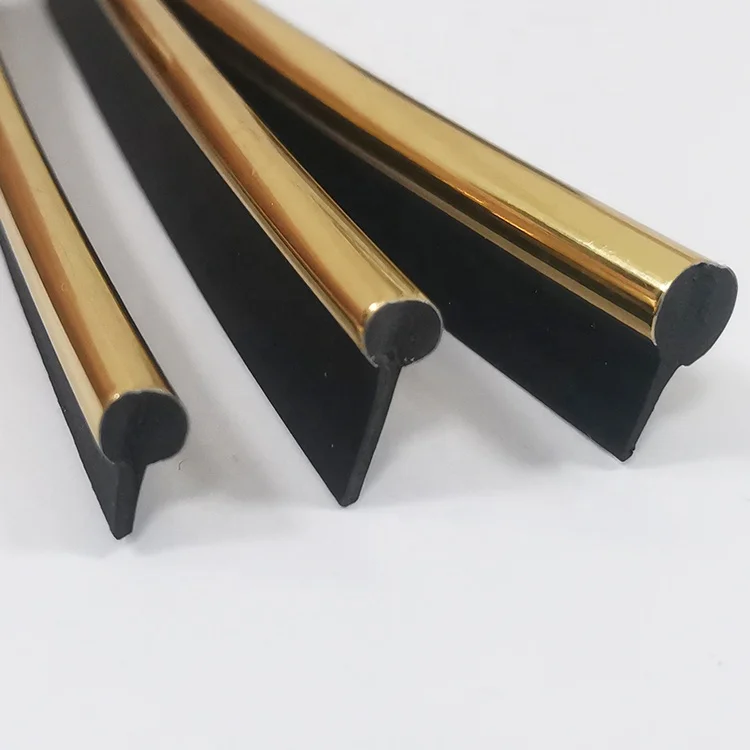

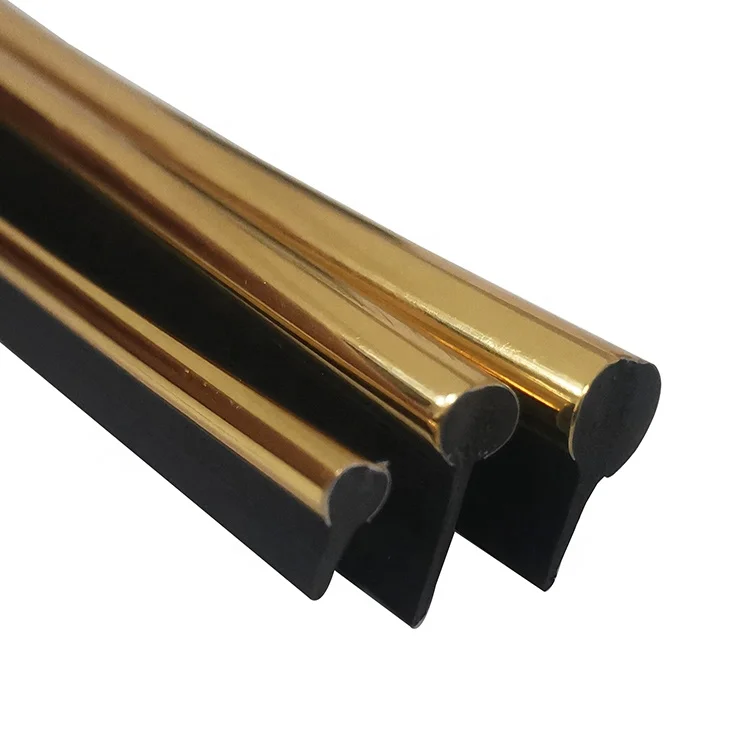

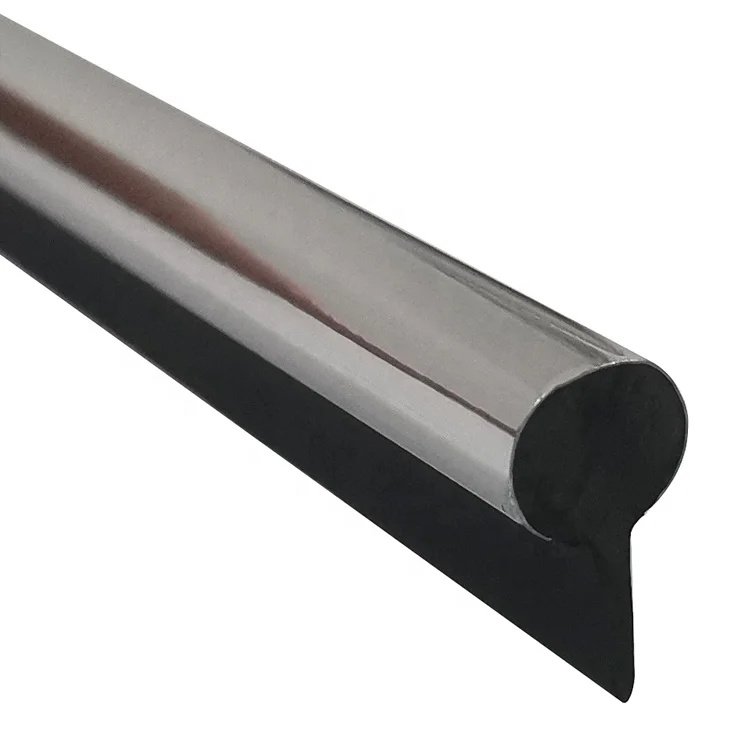

Right now we’re seeing co-extruded PVC/TPV blends, low-VOC acrylic PSAs, and pre-taped profiles that shave minutes off each sash. Many customers say they prefer suppliers that supply both raw extrusions and ready-to-stick formats. Surprisingly, design teams also ask for color-matched trims to make seals “disappear”—and yes, even chrome or gold finishes for upmarket interiors.

Product spotlight (and why it matters)

One interesting crossover from furniture to fenestration: Customized Sizes Colorful Flexible Sofa and Furniture Chrome Gold PVC Plastic Edging Strip. Originating from Xiangjiang Street South, Jinggangshan Road west, Qinghe County, Xingtai City, Hebei Province, it’s designed for furniture edges but the extrusion and adhesive-lamination know‑how overlaps cleanly with window trim and sealing needs. Actually, this kind of decorative-yet-durable edge gives a hint of what modern window seal strip adhesive companies can deliver: flexible materials, aesthetic finishes, and consistent bonding.

| Spec (≈, real-world may vary) | Detail |

|---|---|

| Material | Flexible PVC with optional metallic/colored finishes |

| Colors/Finish | Chrome, gold, and custom tones; matte or glossy |

| Width/Thickness | Customized per drawing; tight tolerances achievable |

| Adhesive options | Acrylic PSA, hot‑melt rubber, or double-sided tapes (pre-applied) |

| Temp range | Around −20°C to 70°C (application-dependent) |

| Cert expectations | RoHS/REACH compliance; ISO 9001 QA frameworks |

From resin to roll: typical process flow

- Material selection: PVC compounds with stabilizers and pigments; optional co-extrusion layers.

- Extrusion & profiling: Calibrated dies, online dimension checks, surface treatment for adhesion.

- Adhesive lamination: Acrylic PSA or hot-melt applied; liner added; curing/dwell where required.

- Testing: Peel adhesion (ASTM D3330), Shore hardness (ASTM D2240), UV aging (ISO 4892), VOC (ISO 16000), temperature cycling and dimensional stability audits.

- Packing & traceability: Lot coding, MSDS/CoC, and install guides.

Service life? For indoor trims, ≈5–10 years is common; exterior window seals vary by UV load and substrate prep. As always, clean surfaces win.

Where it’s used

Windows and doors, furniture edging, RV and rail interiors, retail display trims, and—oddly enough—acoustic panels where a neat sealed edge helps. Installers like pre-taped versions because, well, fewer glues on the bench.

Vendor landscape: what buyers compare

| Vendor | Core adhesive | MOQ | Lead time | Customization | Cert focus |

|---|---|---|---|---|---|

| Hebei-based OEM (featured) | Acrylic PSA / hot‑melt | Flexible, project-based | ≈10–25 days | Color, width, liner, finish | ISO 9001, RoHS/REACH |

| Regional OEM A | Rubber-based HM | Medium | 3–5 weeks | Widths, die-cuts | Basic QA docs |

| Global Brand B | High-tack acrylic | Higher | 4–8 weeks | Extensive | Broad compliance set |

Field notes and mini case studies

- European window fabricator switched to pre-taped profiles; client-reported air leakage dropped ≈18% after better surface prep and consistent PSA thickness.

- Furniture OEM integrated chrome-edge PVC trims; rework fell 27% (internal log) because installers no longer hand-apply contact cement. Looks nicer too—subjective, but widely echoed.

Customers frequently mention fewer callbacks when substrates are cleaned with IPA, adhesive liner is removed at low angle, and pressure is applied (think 15–20 N/cm with a roller). Small habits, big wins.

Checklist when shortlisting window seal strip adhesive companies

- Ask for peel data (ASTM D3330) at 24h, and UV-aged values (ISO 4892) for 250–500 h.

- Confirm VOC/odor claims with ISO 16000 reports for indoor installs.

- Review lead times against your line speed; pre-taped stock can stabilize takt time.

- Request install SOPs; the good suppliers share them without fuss.

References

- ASTM D3330: Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape.

- ISO 4892 (Plastics — Methods of exposure to laboratory light sources); ISO 16000 (Indoor air — VOC measurement); ISO 9001 (Quality management systems).

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025