Top Window Seal Strip Adhesive Manufacturers & Suppliers

Aug . 19, 2025 01:20 Back to list

Top Window Seal Strip Adhesive Manufacturers & Suppliers

Understanding Window Seal Strip Adhesive Solutions and Industry Trends

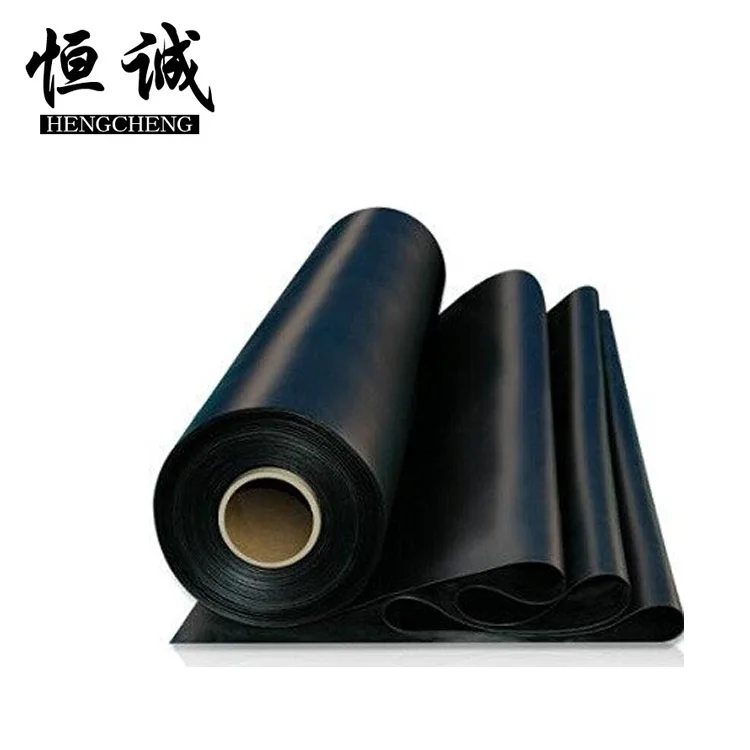

The landscape for window seal strip adhesive companies is rapidly evolving, driven by an increasing global demand for enhanced energy efficiency, superior sound insulation, and robust environmental protection across various sectors including construction, automotive, and industrial enclosures. These specialized firms are at the forefront of developing innovative sealing solutions that address critical performance requirements, often leveraging advanced materials like EPDM rubber, silicone, and various thermoplastic elastomers (TPEs). A prime example of such a critical component is the EPDM Rubber Extrusion Weatherstrip Flat Cabinet Door Rubber Seal Strip, a product engineered for exceptional durability and sealing capabilities. The market is trending towards highly customized solutions, where manufacturers are expected to provide products that can withstand extreme temperatures, UV radiation, ozone exposure, and aggressive chemicals, while maintaining low compression set and excellent elastic recovery. This necessitates a deep understanding of material science, advanced manufacturing techniques, and stringent quality control protocols to ensure long-term performance and reliability in diverse application environments, making the selection of a reputable window seal strip adhesive manufacturer paramount for project success and longevity.

The drive for sustainable building practices and stricter automotive emissions standards further amplifies the need for high-performance window seal strip adhesive products. Leading window seal strip adhesive suppliers are investing heavily in research and development to develop eco-friendly materials and production methods that reduce carbon footprints and comply with international environmental regulations such as RoHS and REACH. This includes the exploration of recyclable polymers and energy-efficient manufacturing processes. Moreover, the demand for multi-functional seals that can integrate additional features like fire resistance, anti-microbial properties, or even intelligent sensors is growing, pushing the boundaries of traditional weatherstrip design. For B2B decision-makers, evaluating a potential window seal strip adhesive company involves not just product specifications but also their commitment to innovation, sustainability, and comprehensive technical support. This holistic approach ensures that the chosen sealing solution will not only meet current project demands but also align with future industry trends and regulatory changes, ultimately contributing to improved product lifespan and reduced operational costs for end-users, underscoring the critical role of specialized window seal strip adhesive factories.

Advanced Manufacturing Processes and Quality Assurance

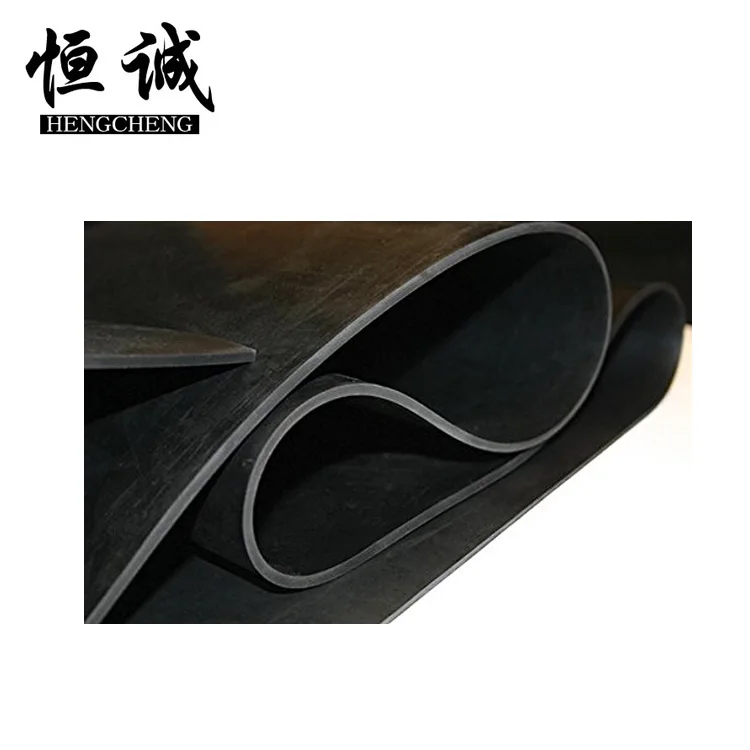

The manufacturing of high-quality window seal strip adhesive products, particularly those made from EPDM rubber, involves a sophisticated multi-stage process designed to ensure material integrity and precise dimensional accuracy. It typically begins with the compounding of raw EPDM polymer with various additives such as curing agents, fillers, plasticizers, and reinforcing agents to achieve desired physical properties like hardness (e.g., Shore A 60-70), tensile strength (e.g., 8-12 MPa), and elongation at break (e.g., 300-500%). This meticulously formulated compound is then fed into an extruder, where it is heated and forced through a die to create the desired profile. This extrusion process is critical for achieving consistent cross-sectional geometry, which is paramount for effective sealing. Following extrusion, the green profile undergoes vulcanization, a chemical process typically involving sulfur or peroxide curing, which cross-links the polymer chains, transforming the material from a plastic state into a durable, elastic rubber. This curing process significantly enhances the seal's resistance to heat, cold, ozone, and UV radiation, extending its operational life considerably.

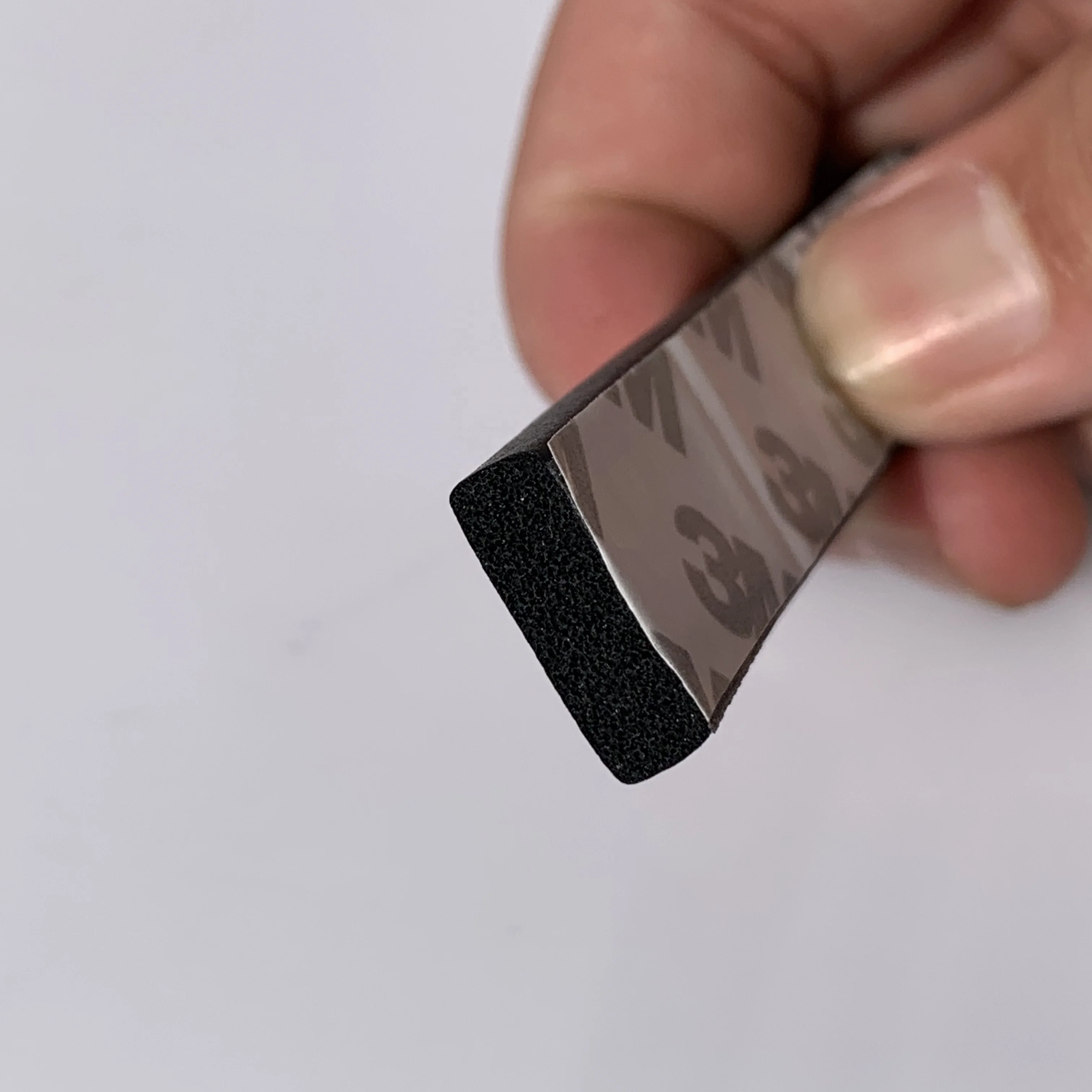

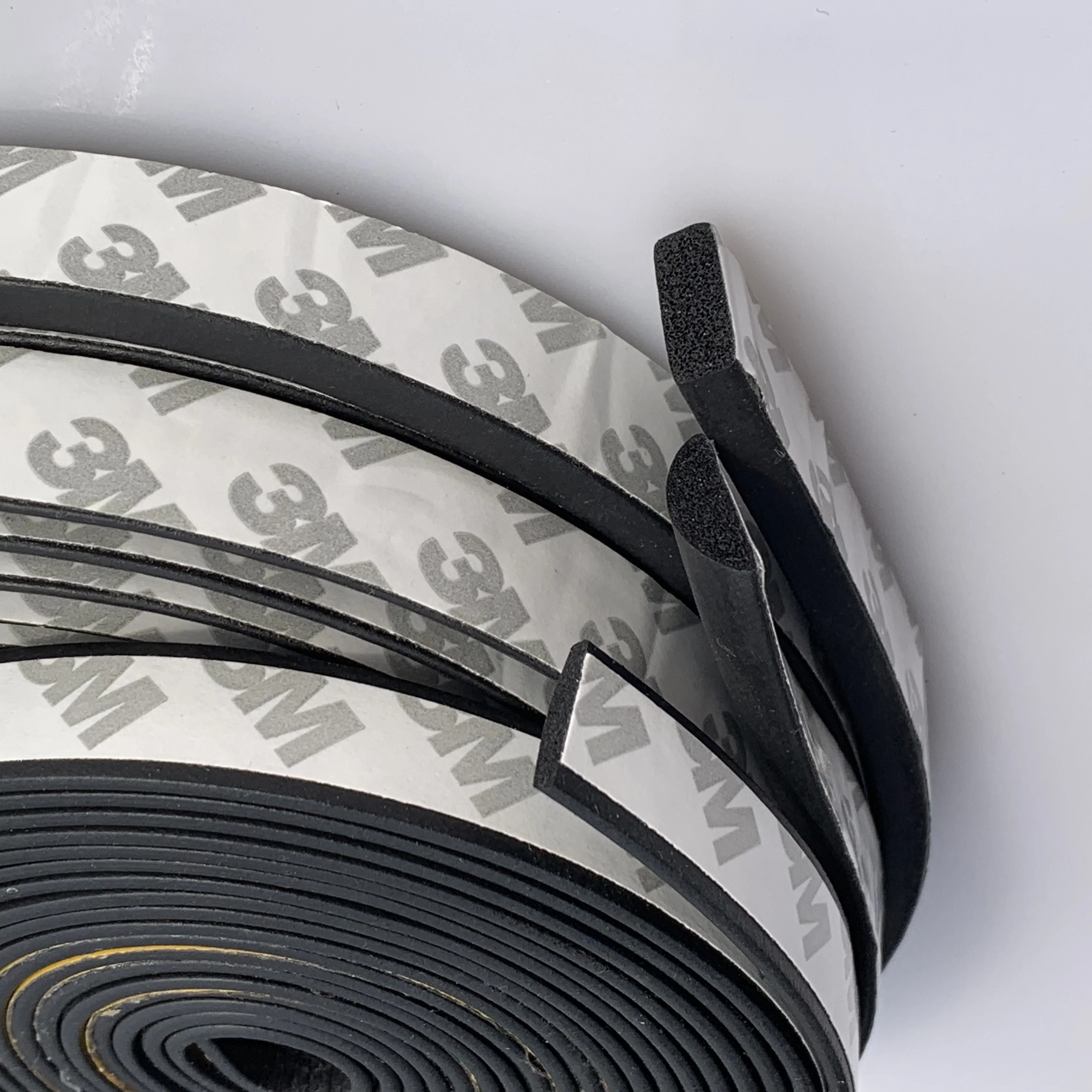

Post-vulcanization, the weatherstrips are cut to precise lengths and may undergo secondary processes such as flocking, coating with friction-reducing agents, or applying pressure-sensitive adhesives (PSAs) for easier installation. Adhesion quality is rigorously tested, ensuring compatibility with various substrates and long-term bond integrity. Quality assurance is integrated throughout the entire manufacturing workflow, adhering to international standards such as ISO 9001 for quality management systems. Individual product batches undergo stringent testing, including dimensional checks, durometer hardness testing, tensile strength and elongation tests, compression set analysis, and accelerated aging tests for ozone and UV resistance. For specialized applications, flame retardancy tests (e.g., UL 94 V-0) or chemical resistance tests may also be performed. This meticulous process ensures that each window seal strip adhesive product leaving the factory meets or exceeds industry benchmarks, providing reliable performance in demanding environments like automotive doors, industrial cabinets, and building fenestration systems. The longevity of these seals, often exceeding 10-15 years in typical applications, underscores the importance of a robust manufacturing and quality control framework by top-tier window seal strip adhesive companies.

Applications and Technical Advantages of EPDM Weatherstrips

EPDM rubber extrusion weatherstrips are highly versatile and find extensive application across a broad spectrum of industries due to their superior performance characteristics. In the automotive sector, they are indispensable for sealing doors, windows, trunks, and hoods, providing excellent protection against water, dust, wind noise, and vibrations, significantly enhancing occupant comfort and vehicle longevity. For industrial applications, particularly in the manufacturing of electrical enclosures, control cabinets, and HVAC systems, these seals ensure a robust barrier against environmental contaminants and maintain internal temperature stability, which is crucial for sensitive electronic components. In the construction industry, EPDM seals are vital for sealing windows, doors, and curtain walls in residential, commercial, and industrial buildings, contributing significantly to thermal insulation, sound attenuation, and moisture management. Their inherent resistance to extreme weather conditions, including UV radiation and ozone, makes them ideal for outdoor exposure, preventing material degradation and maintaining sealing integrity over decades.

The technical advantages of EPDM as a material for seal strips are numerous. It exhibits exceptional resistance to heat and cold, performing consistently across a wide temperature range, typically from -40°C to +120°C. Its outstanding resistance to weathering, ozone, and UV light ensures that the seals do not crack, harden, or become brittle over time, which is a common issue with inferior rubber types. EPDM also boasts excellent compression set, meaning it recovers its original shape well after prolonged compression, maintaining its sealing force over long periods. This is crucial for applications requiring continuous sealing performance. Furthermore, EPDM is resistant to many polar solvents, acids, and alkalis, making it suitable for industrial environments where chemical exposure is a concern. The integration of high-quality adhesives by leading window seal strip adhesive companies further enhances ease of installation and long-term adhesion to various substrates like metal, plastic, and glass. This combination of material superiority and adhesive innovation ensures optimal performance in critical sealing applications, providing energy savings through improved insulation and extending the service life of sealed components.

Selecting a Leading Window Seal Strip Adhesive Company: A Comparative Analysis

Choosing the right partner among the myriad of window seal strip adhesive companies requires a comprehensive evaluation beyond just product price. B2B buyers and technical specifiers must assess several critical factors to ensure long-term value and reliability. Key considerations include the manufacturer's expertise in material science, their production capabilities, commitment to quality assurance, and ability to offer customized solutions. A reputable window seal strip adhesive manufacturer should demonstrate a proven track record, often spanning decades, in producing high-performance rubber extrusions. Their facilities should adhere to international manufacturing standards, such as ISO/TS 16949 for automotive applications or specific industry certifications where applicable. Furthermore, the supplier's capacity to handle various order volumes, from prototyping to large-scale production, coupled with efficient logistics and global distribution networks, is vital for maintaining supply chain stability.

Below is a comparative overview highlighting key parameters when evaluating potential window seal strip adhesive suppliers. This data is synthesized from general industry benchmarks and common B2B requirements, aimed at providing a framework for informed decision-making. Companies seeking specific window seal strip adhesive quotes should engage directly with suppliers to discuss their unique project requirements and receive tailored proposals. The ability of a window seal strip adhesive exporter to navigate complex international trade regulations and provide seamless global delivery is also a significant differentiator, especially for multinational corporations.

| Criterion | Leading Manufacturer (e.g., Pulongte) | Standard Supplier | Emerging Factory |

|---|---|---|---|

| Material Expertise | EPDM, Silicone, PVC, TPE (Custom Compounds) | EPDM, PVC (Limited Customization) | Basic Rubber Types (Standard Formulations) |

| Manufacturing Certifications | ISO 9001, RoHS, REACH, IATF 16949 (Automotive) | ISO 9001 | Basic or None |

| Production Capacity | High volume, multiple extrusion lines, 24/7 operation | Medium volume, standard shift operation | Low volume, limited capacity |

| Lead Time (Average) | 2-4 weeks (Standard), 4-8 weeks (Custom tooling) | 4-6 weeks (Standard), 8-12 weeks (Custom tooling) | 6-10+ weeks (Variable) |

| Customization Capabilities | Full design, material, adhesive, and finishing customization | Limited profile modification, standard adhesives | Minimal to none |

| Technical Support | Dedicated engineering support, application guidance, post-sales service | Standard sales support, basic technical data | Limited technical assistance |

| Minimum Order Quantity (MOQ) | Flexible, supports prototyping to mass production | Generally higher | Typically high, less flexibility |

Custom Solutions, Case Studies, and Client Trust

In a dynamic market, the ability of window seal strip adhesive companies to offer tailored solutions is a significant competitive advantage. Many industrial and architectural projects require seals with specific profiles, unique material compounds, custom adhesive types, or specialized finishes that are not available off-the-shelf. Leading manufacturers excel in this domain, providing comprehensive engineering support from initial concept and CAD design to prototype development and final production. This often involves collaborative design reviews, material selection consultations, and rigorous testing of custom samples to ensure the seals integrate seamlessly with the client's application and meet all performance criteria. Customization extends to integrating features like metal inserts for structural rigidity, multi-durometer co-extrusion for varied flexibility in different sections of the seal, or special surface treatments for enhanced slip reduction or aesthetic appeal. The flexibility to meet niche requirements sets a premium window seal strip adhesive factory apart from standard suppliers.

Consider a real-world application: A leading manufacturer of high-end industrial machinery required a custom EPDM seal strip for its new range of outdoor electrical control panels. The seal needed to withstand extreme temperature fluctuations (-30°C to +80°C), continuous UV exposure, and provide an IP67 rating for dust and water ingress protection. A specialized window seal strip adhesive company partnered with them, designing a unique hollow-bulb profile with a high-tack, outdoor-grade acrylic pressure-sensitive adhesive. Through iterative prototyping and comprehensive environmental testing in accordance with ASTM D2000 standards, the final product exceeded expectations, ensuring the panels' longevity and reliability in harsh conditions. Another case involved a major automotive OEM needing a lightweight, highly compressible EPDM seal for vehicle windows to reduce cabin noise. The chosen window seal strip adhesive manufacturer developed a micro-cellular EPDM foam seal with an integrated adhesive layer, which significantly improved acoustic dampening while contributing to overall vehicle weight reduction, directly addressing the OEM's stringent performance and efficiency goals. These examples underscore the invaluable expertise offered by experienced window seal strip adhesive manufacturers.

Frequently Asked Questions (FAQs) and Trust Building Elements

Building trust with B2B clients is paramount for window seal strip adhesive companies. Transparency, clear communication, and comprehensive support are key pillars. A robust FAQ section addresses common queries proactively, demonstrating a manufacturer's commitment to customer service and technical guidance.

-

Q: What is the typical service life of an EPDM window seal strip?

A: High-quality EPDM weatherstrips, when properly installed and exposed to typical environmental conditions, can last 10-20 years or even longer. Their excellent resistance to UV, ozone, and temperature extremes ensures long-term integrity, minimizing the need for frequent replacements and reducing total cost of ownership. Durability is a hallmark for reliable window seal strip adhesive products.

-

Q: What are the lead times for custom window seal strip orders?

A: For custom profiles requiring new tooling, lead times typically range from 4 to 8 weeks, including design, prototyping, and initial production. Repeat orders for existing custom designs usually have shorter lead times, often 2-4 weeks, depending on order volume and current production schedules. Reputable window seal strip adhesive suppliers provide clear timelines.

-

Q: What quality certifications do your products hold?

A: Our manufacturing processes adhere to ISO 9001:2015 quality management standards. Our materials comply with international environmental directives such as RoHS and REACH. For automotive applications, we ensure compliance with IATF 16949 standards, reflecting our commitment to the highest quality benchmarks within the realm of window seal strip adhesive exporters.

-

Q: Do you offer warranty on your seal strips?

A: Yes, we provide a standard warranty against manufacturing defects and material failures for a specified period (e.g., 5 years) under normal operating conditions. Our dedicated customer support team is available to assist with any product performance inquiries or technical challenges, ensuring satisfaction for clients working with a reliable window seal strip adhesive company.

Furthermore, transparent delivery cycle descriptions and robust warranty commitments significantly enhance client confidence. Most leading window seal strip adhesive manufacturers provide detailed logistical plans, including estimated shipping times for domestic and international orders, and offer various shipping options to meet urgent demands. Post-sales support, including technical assistance for installation, troubleshooting, and maintenance, reinforces the long-term partnership value. This holistic approach ensures that not only are high-quality products delivered, but clients also receive comprehensive support throughout the entire product lifecycle, solidifying the reputation of reliable window seal strip adhesive factories in the market.

References

- ASTM International. (2023). Standard Practice for Rubber Products in Automotive Applications. ASTM D2000.

- International Organization for Standardization. (2015). Quality management systems — Requirements. ISO 9001:2015.

- European Chemicals Agency. (2006). Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation. EC No 1907/2006.

- International Automotive Task Force. (2016). Quality management system requirements for automotive production and relevant service parts organizations. IATF 16949:2016.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025