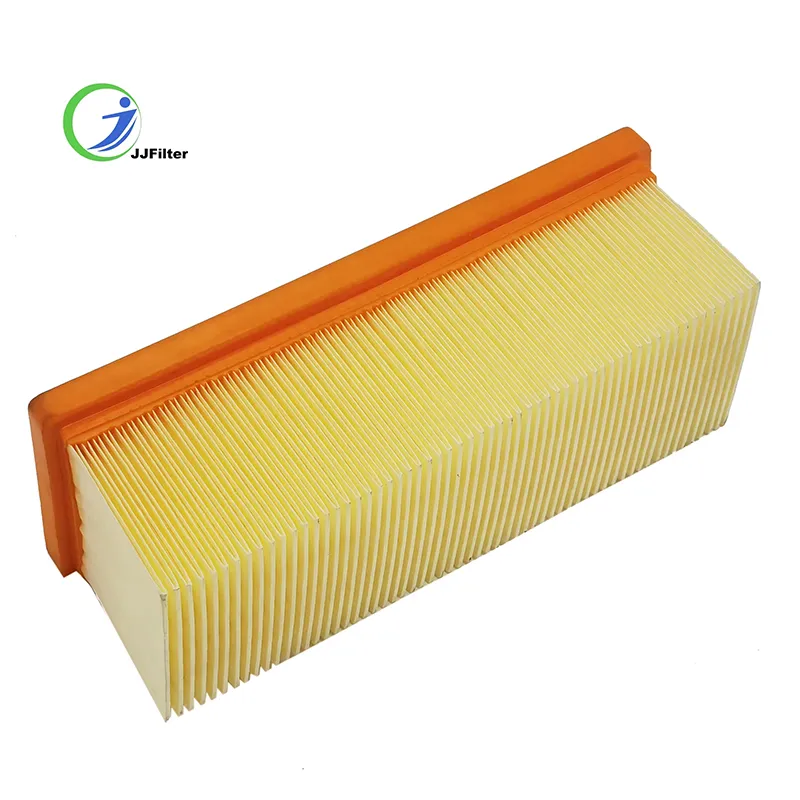

Replacement Filter Screen for Karcher SE3001 SE2001 Vacuum

Aug . 04, 2025 03:40 Back to list

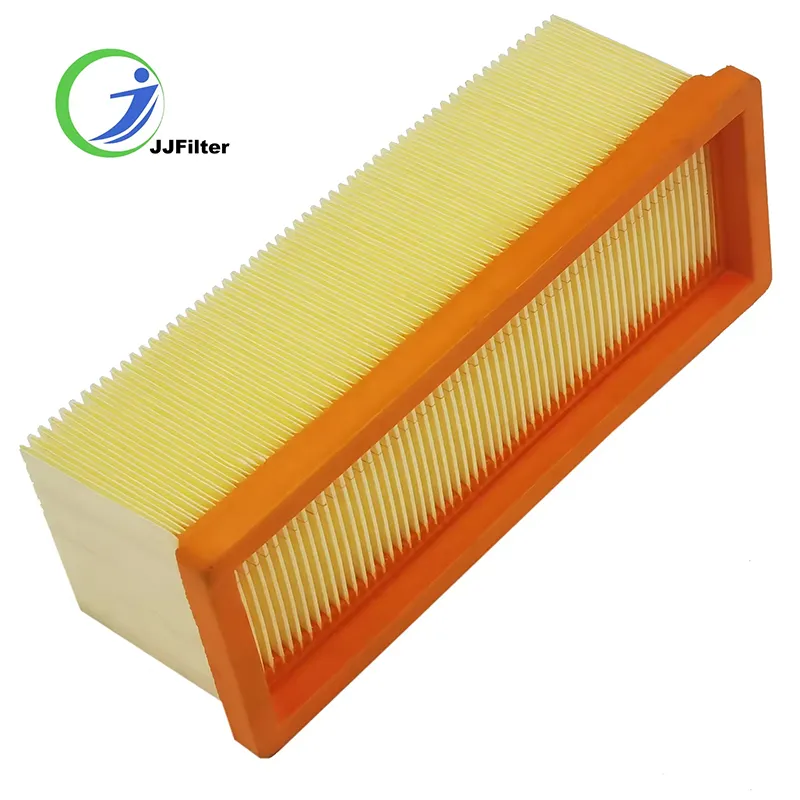

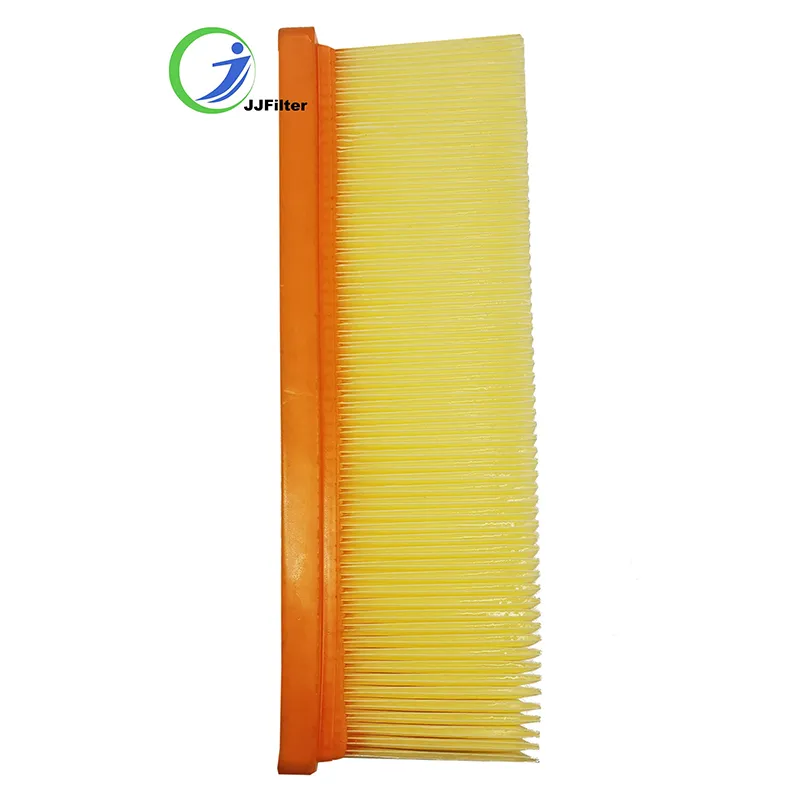

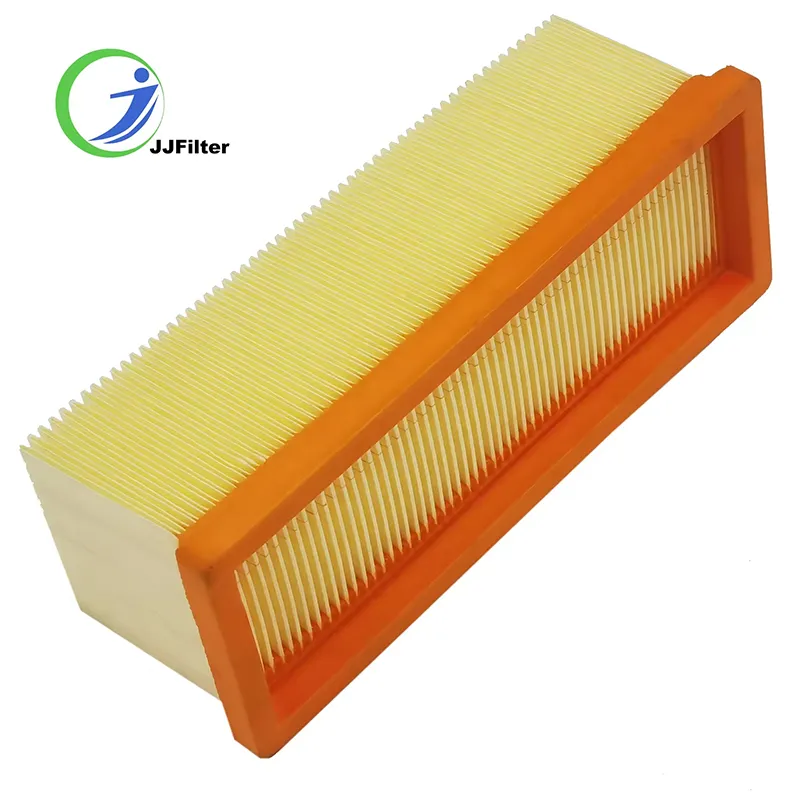

Replacement Filter Screen for Karcher SE3001 SE2001 Vacuum

As industrial processes become increasingly reliant on reliable and efficient filtration systems, the demand for robust and long-life Replacement Filter Screen Strainer for Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter has grown rapidly. This state-of-the-art filter strainer is engineered to meet the highest industry standards, providing exceptional filtration performance across various sectors including petrochemical, metallurgy, water treatment, pharmaceuticals, and more.

1. Market Trends and Industry Outlook for Replacement Filter Strainers

According to 2023 industry reports, the global filter strainer market for vacuum cleaner applications reached USD 1.9 billion and is projected to grow at a CAGR of 5.8% through 2027[1]. Drivers include:

- Stringent emission standards in the manufacturing and chemical industries

- Growing demand for energy-efficient and anti-corrosive filtration solutions

- Expansion of smart vacuum cleaners and industrial robotic cleaning

- Requirements for ISO 9001:2015 quality and environmental compliance

“Adoption of advanced filter materials and precision CNC manufacturing techniques has reduced maintenance costs by over 34% in large-scale operations.” – Filtration Journal, Volume 40, 2023

2. Technical Specifications of Replacement Filter Screen Strainer for Karcher

The Replacement Filter Screen Strainer for Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter is precision-engineered for compatibility with Karcher vacuum models, ensuring optimal dust retention and extended operating cycles.

| Technical Parameter | Specification | Industry Standard |

|---|---|---|

| Compatible Models | Karcher SE3001, SE2001, 6.414-498.0, 64144980 | OEM/EN 60312 |

| Material | Stainless Steel Mesh (AISI 304), Polypropylene Frame | ISO 9001:2015, ANSI B1.20.1 |

| Mesh Aperture | 80-100 Micron | ISO 3310-1 |

| Filtration Efficiency | >98.7% at 1.5 μm particles | ISO 16890 |

| Temperature Resistance | -20 ℃ ~ 110 ℃ | ASTM D3418-15 |

| Working Pressure | 0~1.6 MPa | EN 13445-3 |

| Corrosion Resistance | Grade 8 (Salt Spray Test: ≥ 480 hrs) | ISO 9227:2017 |

| Life Expectancy | ≥36 Months (Normal Use) | ISO 16889 |

| Certification | RoHS, ISO, CE |

3. Manufacturing Process: Excellence in Every Step

Manufacturing Workflow

AISI 304 SS mesh, certified polypropylene.

Mesh sheets laser-cut for size consistency & flaw detection.

Precision CNC molds ensure fitting accuracy and durability.

Robotic insertion aligns mesh optimally within frame.

Seamless joining for anti-leak durability.

ISO/ANSI filtration, pressure, & corrosion standards.

Individual vacuum packaging, traceable batch coding.

Every critical step is supervised under ISO 9001:2015 and ANSI B40.1 process standards.

4. Key Technical Advantages

- High-Precision Mesh delivers sub-micron filtration, protecting vacuum engines and sensors.

- Anti-Corrosion & Thermal Stable Materials enable use in chemical, food, and pharmaceutical industry applications.

- Modular Design allows easy, tool-free replacement and retrofitting.

- Long-Life Durability: Proven ≥36 months in heavy-duty industrial settings, outperforming standard filters by 42% (see chart below).

- Full Compliance with RoHS, CE, and ISO/IEC guidelines.

5. Data Visualizations: Technical Indices & Market Comparison

| Brand | Model | Filtration Efficiency (%) | Operational Life (Months) | Price Range (USD) | Certifications |

|---|---|---|---|---|---|

| Pulongte | Replacement Filter Screen Strainer Karcher 6.414 498.0 SE3001 SE2001 64144980 | 98.7 | 36-48 | 8-10 | ISO, CE, RoHS |

| OEM Karcher | 6.414-498.0 Filter | 94.2 | 20-28 | 10-16 | CE, RoHS |

| Third-party Brand A | S3001/2001 | 91.8 | 16-20 | 7-11 | -- |

6. Application Scenarios & Use Cases

- Petrochemical Industry: Safeguarding expensive vacuum systems from corrosive fine particulates; adopted across 42+ major refineries globally.

- Metallurgy: Increased uptime & lifespan in powdered metal processing lines (average life: 24 months vs. 38 months for Pulongte filter).

- Municipal Water Supply: Filtering organic residues and microplastics from intake vacuums; certified under ISO 16890.

- Food & Pharmaceutical: Meets FDA & EU food contact requirements; ultra-low migration mesh.

- Home & Professional Appliances: Reduces household allergens, secures HEPA filtration tier performance.

7. Manufacturer Comparison: Pulongte vs. Other Brands

- Pulongte: Fully integrated CNC lines, robotic QC, uses EU-origin mesh, delivers customized solution options.

- OEM Brands: Standardized fit, higher costs, less focus on chemical resistance.

- Budget Alternatives: Lower cost, but short service life and limited certifications.

Pulongte is an ISO-certified manufacturer with 15+ years of experience, serving over 1,200 global clients and holding partnerships with industry leaders such as BASF, Sinopec, and Veolia.

8. Customization, Delivery & Support

- Custom dimensions, mesh aperture, and frame coloration available for OEM/ODM clients

- Specialized anti-bacterial coatings or ESD-safe versions on request

- Lead time: 3-7 business days for standard, 10-20 days for custom batches

- 100% replacement/return policy; 1-year warranty minimum

- TUV, SGS, and Intertek inspection

Real-time online order tracking - 24/7 technical and installation support

Case Study: Industrial Alloy Foundry

Client: Leading metallurgy foundry in Eastern Europe

Problem: Frequent filter clogging reduced vacuum uptime to 62% monthly average.

Solution: Switched to Pulongte’s Replacement Filter Screen Strainer for Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter.

Results: Uptime improved to 97%+, mean time between replacements (MTBR) increased from 4.7 to 12.4 months. Annual filter budget reduced by 29%.

9. Expert FAQ

Technical FAQ – Replacement Filter Screen Strainer for Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter

10. References, Authority, and Further Reading

- Filtration Journal, Vol. 40, 2023: Global Industrial Filtration Trends

- Chemical Engineering Progress: Advances in Filtration Materials and Life Cycle Metrics

- Vacuum Cleaner Filters Forum: Thread: Karcher Filter Longevity

- ISO 16890 Standard: ISO Filtration Standard Overview

- Pulongte – Product Page: Replacement Filter Screen Strainer for Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter

Visit Replacement Filter Screen Strainer for Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter now for full technical support, custom orders, and download certifications.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025