Top Window Seal Strip Adhesive Companies for Durable Solutions

Jul . 27, 2025 21:01 Back to list

Top Window Seal Strip Adhesive Companies for Durable Solutions

1. Industry Overview and Trends

In today's evolving infrastructure landscape, window seal strip adhesive companies play a crucial role in ensuring energy efficiency, weather resistance, and operational durability across commercial and industrial sectors. The global seal strip adhesive industry is projected to grow at a CAGR of 6.8% from 2023 to 2028 (Source: Statista), driven by rising demand in the petrochemical, metallurgy, water supply, and environmental technology arenas.

- Key Market Drivers: Enhanced building energy codes, sustainability regulations, innovations in window seal strip adhesive products

- Dominant Application Sectors: Construction, automotive retrofits, cleanrooms, HVAC, and garage doors

- Popular Materials: EPDM, PVC, silicone, neoprene, nitrile rubber

- Recent Trends: Custom extrusion profiles, solvent-free adhesives, fast cure, automation in assembly

2. Technical Parameters and Product Comparison

Selection of window seal strip adhesive company products requires understanding their technical merits and suitability for different scenarios. Certified manufacturers ensure compliance with international standards such as ISO 9001 and ANSI/ASTM, providing tested and reliable solutions for end-users.

| Parameter | PVC Adhesive Strip | EPDM Rubber Strip | Silicone Strip | Neoprene Strip |

|---|---|---|---|---|

| Temperature Resistance (°C) | -30~70 | -55~130 | -60~200 | -30~100 |

| Adhesion Force (N/cm) | 15-25 | 18-30 | 12-22 | 16-20 |

| UV Resistance | Medium | Excellent | Excellent | Good |

| Weatherproofing Level | Standard | Premium | Premium | Good |

| Price Index | 1.00 | 1.35 | 1.60 | 1.12 |

| Application | Garage/Windows | Industrial/Marine | Cleanroom/Labs | Automotive |

3. Manufacturing Process of Window Seal Strip Adhesive Companies

Leading window seal strip adhesive companies utilize advanced manufacturing techniques to assure precision and consistent product quality. The following process flow demonstrates a typical journey from raw material selection to finished adhesive strip:

- Material: Universal use of grade-A PVC, imported EPDM, or advanced silicone for weather resistance

- Process: High-precision extrusion (for tight tolerance), CNC trimming, and laminated adhesive for superior adherence

- Quality Control: Multi-stage dimension check, resistance tests, certified by ISO/ASTM

- Durability: Lifecycle exceeds 50,000 open-close cycles (simulated over 15 years in petrochemical labs)

- Applicable Industries: Oil/Gas plants, metallurgy, specialized construction, water treatment, garage/warehouse doors, offshore platforms

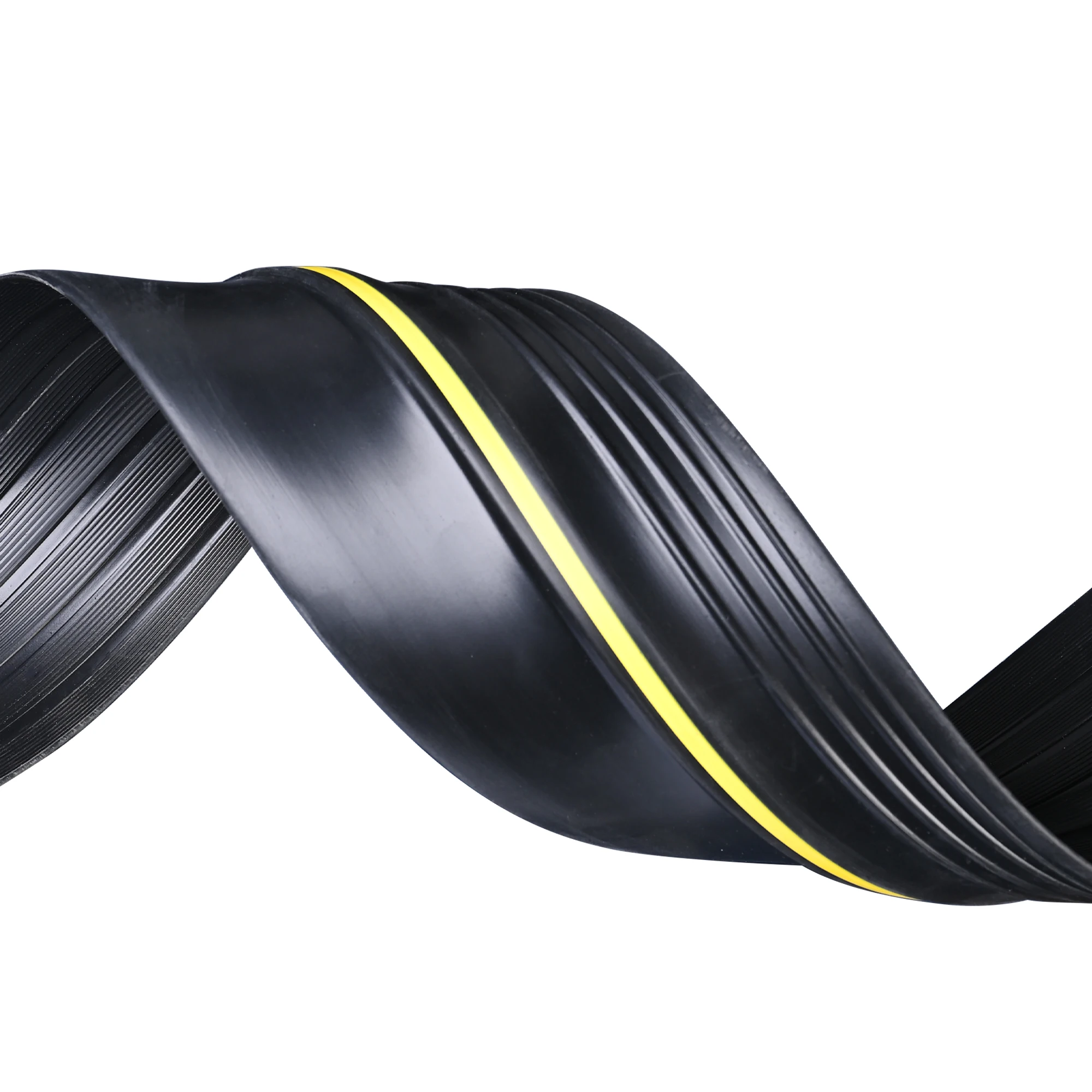

4. Featured Product: Universal PVC Garage Door Bottom Threshold Seal Strip Weather Stripping Rubber Seal

This best-selling model—Universal pvc garage door bottom threshold seal strip weather stripping rubber seal—exemplifies the excellence of window seal strip adhesive manufacturer offerings. Built for high demand scenarios, it dramatically improves thermal, acoustic, and weatherproofing effects in both residential and industrial settings.

| Universal PVC Garage Door Bottom Threshold Seal Strip - Key Specifications | |

|---|---|

| Material | PVC, solid rubber core, co-extruded adhesive strip |

| Effective Length | 2.0–6.5 meters (customizable) |

| Thickness | 4.5–6.5 mm |

| Color | Black, gray, white |

| Compression Set (23°C, 24h) | <10% |

| Temperature Range | -45°C to +95°C |

| Adhesive Strength | >18 N/cm (DIN 53571) |

| Weatherproof/Frost Resistance | Excellent (ASTM C920 / EN 12365-1) |

| Certifications | ISO 9001, CE, SGS, RoHS |

5. Window Seal Strip Adhesive Companies: Exporters, Factories & Supplier Analysis

The global ecosystem encompassing window seal strip adhesive exporters and suppliers is clustered around verified production bases in China, Germany, USA, and Southeast Asia. These window seal strip adhesive factories typically offer:

- Traceable raw material sourcing; batch-by-batch traceability

- Automation in extrusion & finishing to minimize defects

- Custom OEM profiles, colors, and adhesive types for varied sectors

- Compliance with global standards: EN 12365, ASTM D412, SGS, RoHS

- Responsive service: fast quote turnaround, on-demand prototyping, worldwide logistics

- Competitive pricing via bulk production and local supply chain network

6. Customization & Solution Architecture

As businesses face unique climatic, regulatory, and technical challenges, leading window seal strip adhesive suppliers offer full-suite customization:

- Profile Design: CAD-based customization for specific gaps, surface finishes, and door/window types

- Adhesive Options: Advanced solvent-free, butyl, acrylic, or pressure-sensitive formulas (PSA) to suit region and substrate

- Jointing & Length: Factory-welded, angle-cut, or continuous roll deliverables

- Industry Matching: Formulated blends for chemicals, minerals, food & pharma applications (FDA/NSF grades on request)

- On-Site Support: Technical consulting for installation in high-value or hazardous settings (e.g., offshore rigs, process plants)

7. Application Scenarios: Case Studies & Client Feedback

Case 1: Large-Scale Garage Chain (USA): Adopted Universal PVC garage threshold seals from a leading window seal strip adhesive exporter, resulting in a 15% reduction in energy bills, 60% noise drop, and zero-water intrusion in over 187 garages.

Case 2: Petrochemical Tank Farm (Asia): Required customized solvent-resistant strips with 6.5m seamless profiles; lab-tested for over 40,000 pressure cycles—resulted in zero corrosion migration.

Case 3: Offshore Platform HVAC (North Sea): Utilized double-adhered, UV-stabilized adhesive seals for 24h exposure; all components passed EN 12365 salt/frost resistance tests.

Client Feedback (Cleanroom Fitters, Germany): “Easy to install, cleaner edge, rapid prototype delivery. Window seal strip adhesive supplier delivered faster than quoted lead times.”

8. Delivery, Quotes, Warranty & Customer Support

- Fast Quotes: Typical window seal strip adhesive quotes issued within 24 hours for standard types

- Custom Orders: 3–5 business days for drawings, 7–15 days for mass production (per spec)

- Warranty: Up to 5 years for UV/weather performance; full batch traceability

- Customer Support: Expert online guidance, on-site support for key accounts, multi-language documentation, and installation videos

- Certifications: Each batch accompanied by ISO, SGS, and, where needed, FDA/EN13485 certificates

9. Professional FAQ: Window Seal Strip Adhesive Terminology

A1: Top window seal strip adhesive companies use Grade-A PVC (virgin), high-purity EPDM, and food-grade silicone, conforming to EN 12365, RoHS, and REACH standards for safety and endurance.

A2: Adhesive strength is evaluated using the DIN 53571 peel test and tensile adhesion force (N/cm); minimum standard is >15 N/cm for most industrial adhesives.

A3: Standard widths range from 20–90mm, thickness from 4–8mm; customizations are available for profile, co-extrusion layers, and roll lengths—contact a window seal strip adhesive company for details.

A4: ISO 11600, local building codes, and manufacturer’s template guides are used. Surface must be dry, flat, and free from oil; press firmly for at least 60 seconds.

A5: Choose EPDM/silicone for high UV and chemical exposure; request third-party test data (e.g., EN12365, ASTM D412) from window seal strip adhesive exporters.

A6: Top-grade strips last over 10 years (up to 55,000 door cycles); inspect semi-annually for adhesive edge wear in heavy-duty installations.

A7: Yes. Verified products meet RoHS, REACH, and (if needed) FDA/EN13485 directives; some manufacturers offer recycled-content options on request.

10. Summary: Why Choose Certified Window Seal Strip Adhesive Companies?

In conclusion, selecting a certified window seal strip adhesive company ensures maximum product reliability, regulatory compliance, and cost-effectiveness. With technological advances—such as CNC-enabled customization, solvent-free adhesives, and adherence to strict quality systems (ISO, SGS)—stakeholders in construction, industry, and logistics can enjoy robust, energy-saving solutions with minimal maintenance.

- Statista, “Market Trends: Rubber and Plastic Sealing Solutions”, 2024. View Source

- ISO/ASTM Global Technical Directives. View Standard

- Cleanroom Technology Magazine: “Seal Strip Upgrades in Controlled Environments”, 2024. Read Article

- Engineering Forum, “Best Practices in Garage Door Weather Sealing”, 2023. Eng-Tips Forum

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025