Acrylic Heat Bender Tool-Type A - Hebei Pulongte Rubber and Plastic Technology Co., Ltd. | Precision, Durability, Efficiency

Oct . 01, 2025 03:30 Back to list

Acrylic Heat Bender Tool-Type A - Hebei Pulongte Rubber and Plastic Technology Co., Ltd. | Precision, Durability, Efficiency

Introduction

The Acrylic Heat Bender Tool-Type A represents a significant advancement in acrylic fabrication technology. Designed for both industrial and DIY applications, this tool enables users to shape acrylic sheets with remarkable precision and efficiency. Manufactured by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., the tool combines innovative engineering with user-friendly design to meet the demands of modern manufacturing. This article explores the Acrylic Heat Bender Tool-Type A's features, advantages, technical specifications, application scenarios, and the company's commitment to quality.

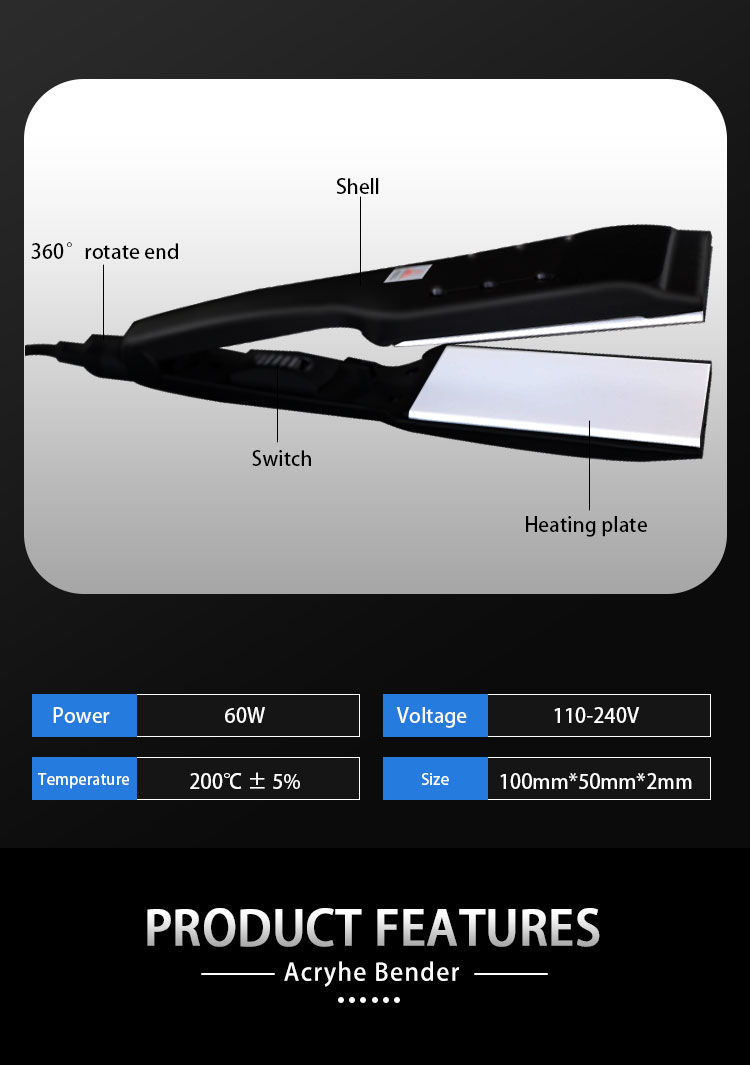

Product Features

The Acrylic Heat Bender Tool-Type A is engineered with several key features that set it apart from traditional acrylic bending methods. One of its standout attributes is its precision temperature control system, which ensures consistent heating and prevents overheating, a common issue in acrylic fabrication. This feature is particularly beneficial for creating complex shapes without compromising the material's structural integrity.

Another notable feature is its ergonomic design. The tool is built with a comfortable grip and a lightweight frame, reducing user fatigue during extended use. Additionally, the adjustable clamping mechanism allows for secure fixation of acrylic sheets, ensuring accurate bending without slippage. This is especially useful for users working on intricate designs or large-scale projects.

The Acrylic Heat Bender Tool-Type A also includes a rapid heating element, which significantly reduces the time required to reach the optimal bending temperature. This efficiency is crucial for both professional manufacturers and hobbyists looking to streamline their workflow. Furthermore, the tool is equipped with heat-resistant components that enhance safety and durability, making it suitable for continuous use in demanding environments.

Advantages of the Acrylic Heat Bender Tool-Type A

One of the primary advantages of the Acrylic Heat Bender Tool-Type A is its versatility. It can be used to create a wide range of shapes, from simple curves to complex 3D structures. This versatility makes it an ideal choice for industries such as signage, lighting, and automotive manufacturing, where custom acrylic components are in high demand.

The tool's user-friendly interface is another significant advantage. Its intuitive controls and clear temperature indicators make it accessible to users of all skill levels. This is particularly beneficial for small businesses or individuals who may not have extensive experience in acrylic fabrication. The low maintenance requirements of the tool further add to its appeal, as it minimizes downtime and reduces operational costs.

Moreover, the Acrylic Heat Bender Tool-Type A is designed with environmental sustainability in mind. Its energy-efficient heating system reduces power consumption, aligning with global efforts to minimize carbon footprints. This eco-friendly approach not only benefits the environment but also appeals to businesses looking to adopt greener practices.

Technical Specifications

The Acrylic Heat Bender Tool-Type A is equipped with advanced technical specifications that ensure optimal performance. Below is a detailed overview of its key parameters:

| Specification | Details |

|---|---|

| Temperature Range | 150°C – 220°C |

| Heating Element | High-efficiency ceramic heater |

| Power Consumption | 1200W |

| Dimensions | 350mm x 200mm x 100mm |

| Weight | 2.5kg |

| Material | Stainless steel and heat-resistant plastic |

| Clamping Mechanism | Adjustable with 360° rotation |

| Control System | Digital temperature display and PID control |

These specifications highlight the tool's ability to deliver consistent results while maintaining safety and efficiency. The digital temperature control ensures precise heating, while the sturdy construction guarantees long-term durability. The adjustable clamping mechanism allows for flexibility in handling different acrylic thicknesses and shapes.

Application Scenarios

The Acrylic Heat Bender Tool-Type A is widely applicable across various industries. In the signage and advertising sector, it is used to create custom-shaped acrylic signs, ensuring a professional and polished appearance. Its precision makes it ideal for producing intricate designs that require exact measurements.

In the lighting industry, the tool is employed to fabricate acrylic lampshades and diffusers. The ability to bend acrylic into complex shapes allows for the creation of unique lighting fixtures that enhance the aesthetic appeal of spaces. For example, the Acrylic Heat Bender Tool-Type A can be used to produce light cover acrylic lampshades with smooth curves and uniform thickness, as seen in the provided images.

The tool is also valuable in the automotive and aerospace industries, where custom acrylic components are required for interiors and exteriors. Its ability to handle large sheets of acrylic makes it suitable for creating dashboards, panels, and other structural elements. Additionally, the 3D metal acrylic trim caps shown in the images demonstrate the tool's capability to produce decorative and functional parts for various applications.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Hebei Pulongte Rubber and Plastic Technology Co., Ltd. is a leading manufacturer of high-quality rubber and plastic products, with a strong focus on innovation and customer satisfaction. Established with a mission to provide reliable solutions for industrial and commercial applications, the company has built a reputation for excellence in the production of acrylic fabrication tools and related components.

With years of experience in the industry, Hebei Pulongte has consistently delivered products that meet the highest standards of quality and performance. The company's commitment to research and development ensures that its products, including the Acrylic Heat Bender Tool-Type A, are equipped with the latest technological advancements. This dedication to innovation is reflected in the tool's design, which combines practicality with cutting-edge engineering.

Hebei Pulongte also emphasizes sustainability in its manufacturing processes, aligning with global trends toward eco-friendly production. The company's export capabilities and supply chain efficiency enable it to serve a diverse range of clients, from small businesses to large-scale manufacturers. This extensive reach is evident in the product images provided, which showcase the company's ability to produce and distribute high-quality tools to international markets.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to the advancements in acrylic fabrication technology. Its combination of precision, durability, and user-friendly design makes it an indispensable tool for professionals and hobbyists alike. Backed by the expertise of Hebei Pulongte Rubber and Plastic Technology Co., Ltd., the tool is a reliable solution for a wide range of applications.

As industries continue to evolve, the demand for efficient and versatile fabrication tools will only grow. The Acrylic Heat Bender Tool-Type A is well-positioned to meet these challenges, offering a blend of innovation and practicality. Whether you are manufacturing custom acrylic components or exploring creative projects, this tool is designed to enhance your workflow and deliver exceptional results.

References

1. National Institute of Standards and Technology (NIST). (n.d.). Materials Measurement Science. Retrieved from https://www.nist.gov

2. NIST. (2023). Standards for Plastics and Polymers. Retrieved from https://www.nist.gov

3. NIST. (2022). Advancements in Manufacturing Technologies. Retrieved from https://www.nist.gov

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025