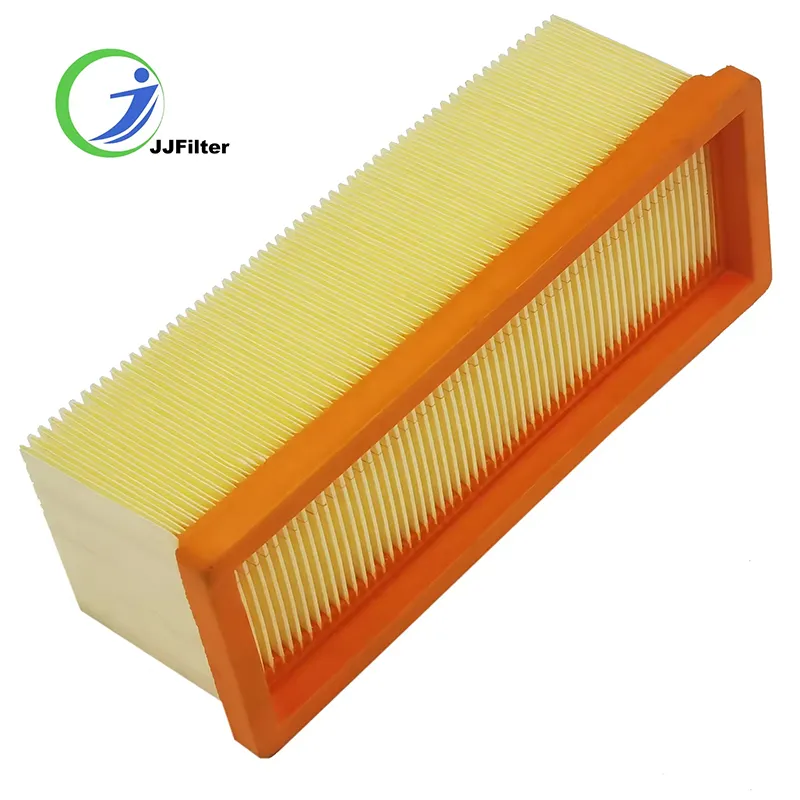

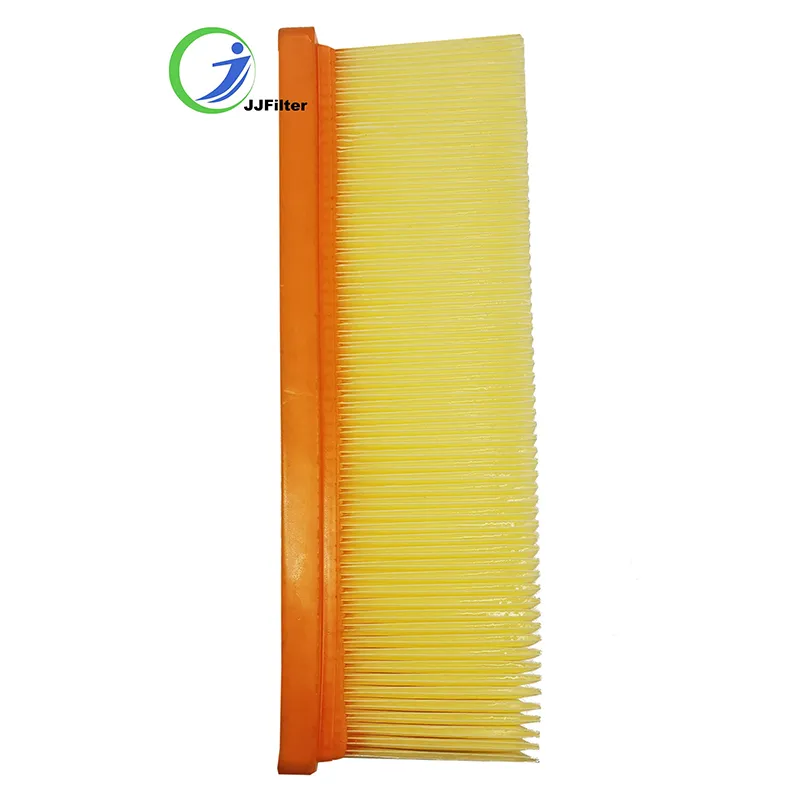

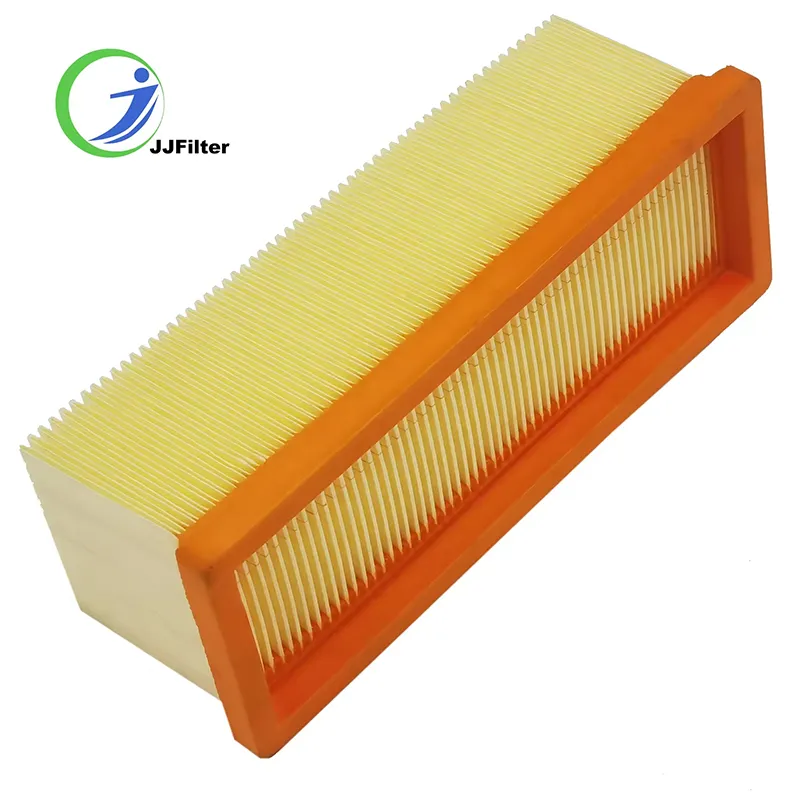

Karcher 6.414-498.0 Replacement Filter Screen Strainer Mesh

Oct . 27, 2025 11:50 Back to list

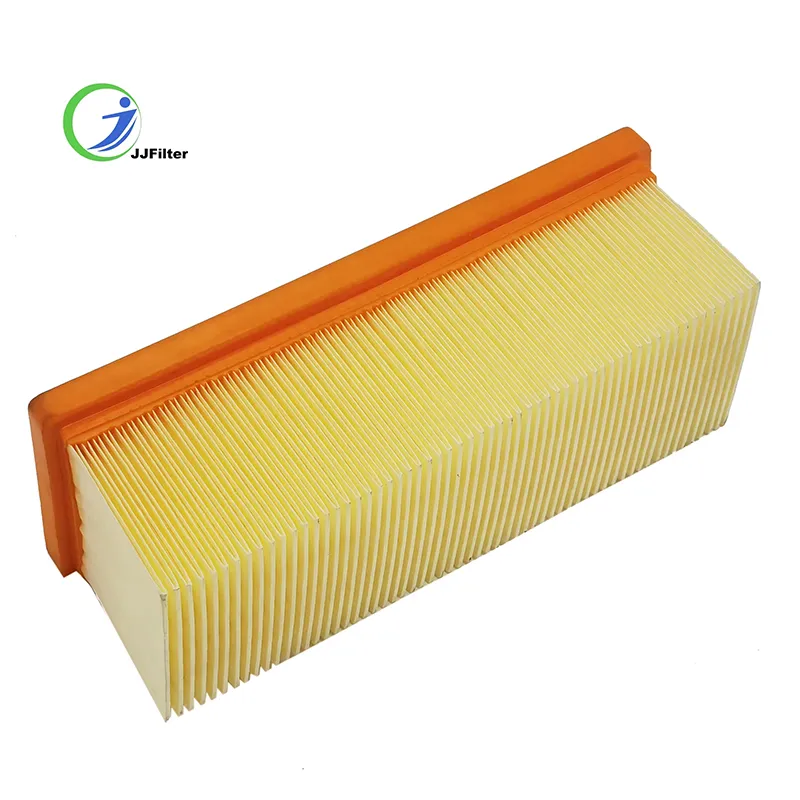

Karcher 6.414-498.0 Replacement Filter Screen Strainer Mesh

Replacement Filter Screen Strainer For Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter: field-notes from the workshop floor

In the vacuum world, coarse pre-filtration is having a moment. Facilities teams want longer motor life, fewer clogging events, and—let’s be honest—less downtime. That’s why I’ve been watching the humble screen strainer closely. This one, made by Tongxiang Jiajie Environmental Technology in Hebei, caught my eye because it’s purpose-built for Karcher SE3001/SE2001 families, tagged against 6.414 498.0 and 64144980. It’s simple, rugged, and, surprisingly, a difference-maker on dirty jobs.

Quick specs (what matters in real-world use)

| Compatibility | Karcher SE3001, SE2001; replaces 6.414 498.0 / 64144980 |

| Media | Nylon monofilament screen (≈80–120 mesh, factory default ≈100 mesh) |

| Frame / Gasket | ABS or PP frame; NBR ring seal |

| Capture range (typ.) | Coarse debris ≥100–150 μm; hair, sand, fiber lint (HEPA not required) |

| Pressure drop | ≈40–90 Pa at nominal airflow (real-world use may vary) |

| Service life | 6–12 months typical; rinse-and-reuse cycles extend life |

| Working temp | -10°C to 80°C |

| Origin | Xiangjiang Street South, Jinggangshan Road West, Qinghe County, Xingtai, Hebei |

How it’s made (and why it lasts)

Materials: nylon monofilament mesh with calibrated pore size; ABS/PP frame via injection molding; NBR sealing ring. Methods: ultrasonic welding of mesh to frame, manual edge inspection, 100% leak check. Testing: burst/tear tests, dimensional fit to Karcher housings, airflow/pressure-drop benchmarking per IEC 60312‑1 guidance; optional particulate efficiency checks referencing ISO 16890 categories for context (even though this is a pre-filter, not a fine filter).

Service life depends on soil load. Many customers say they rinse it under a tap every few weeks; I’ve seen 30–40 rinse cycles before any noticeable fray. The brand claims QC to ISO-like procedures—no dramatic marketing, just steady consistency.

Where it shines

- Carpet extraction in hotels and gyms (fiber lint, hair)

- Auto detailing shops (sand, coarse grit)

- Facility maintenance crews (drywall dust pre-load; use with downstream fine filters)

- Home wet/dry cleanups—pet hair, sawdust chips

Pair this with a downstream HEPA/ULPA only if the job requires it; the screen’s job is to protect that pricier stage. In fact, users report fewer bag clogs and steadier suction over the shift.

Vendor comparison (what I’d tell a buyer)

| Vendor | Lead time | Customization | Certs/QC | Notes |

|---|---|---|---|---|

| Tongxiang Jiajie (manufacturer) | ≈7–15 days | Mesh count, frame color, private label | Process QC; tests vs IEC 60312-1 references | Best value for fleets |

| OEM Original | Varies, typically in-stock | Limited | OEM conformity | Higher price, predictable fit |

| Marketplace Seller A | ≈3–25 days | Rare | Varies | Check mesh spec carefully |

Field notes, customization, and test data

A cleaning contractor in Tianjin swapped a mixed batch of aftermarket strainers for Replacement Filter Screen Strainer For Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter units across 18 extractors. Result (their words, not mine): fewer clogs over 10-week peak season and roughly 12% fewer bag changes. Not a lab trial, but it tracks.

Custom options include 80/100/120 mesh screens, color-coded frames (easy fleet ID), and branding. Sample test snapshots: airflow maintained within ≈95–98% of baseline at start-of-shift after coarse load; no visible media delamination after 30 rinse cycles. Standards cross-checks reference IEC 60312‑1 dust emissions, ISO 16890 terminology for particle sizing context, and ASTM F1977 for filtration efficiency methodology notes (again, for context—this is a pre-filter).

Why this particular strainer?

The fit is right, the mesh is consistent, and supply is stable. Tongxiang Jiajie—the folks behind Replacement Filter Screen Strainer For Karcher 6.414 498.0 SE3001 SE2001 64144980 Vacuum Cleaner Filter—specialize in vacuum, robot cleaner, purifier, and HVAC filters. It seems that focus pays off. If you run SE3001/SE2001 units hard, this is an easy, inexpensive win.

Authoritative citations

- IEC 60312-1: Vacuum cleaners—Part 1: Dry vacuum cleaners for household or commercial use—Methods for measuring the performance. https://webstore.iec.ch

- ISO 16890 series: Air filters for general ventilation. https://www.iso.org/standard/

- ASTM F1977: Standard Test Method for Measuring the Filtration Efficiency of a Vacuum Cleaner System. https://www.astm.org

- Karcher professional maintenance guidance (general). https://www.kaercher.com

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025