Automobile Sealing Strip Series Top Exporter Factory Quality Seals

Jun . 08, 2025 02:03 Back to list

Automobile Sealing Strip Series Top Exporter Factory Quality Seals

- Evolution of sealing technology in automotive manufacturing

- Core technical advantages defining modern sealing systems

- Global market data and material science breakthroughs

- Comparative analysis of leading manufacturing specialists

- Custom design capabilities for specific vehicle requirements

- Real-world implementation across vehicle categories

- Strategic sourcing from specialized production partners

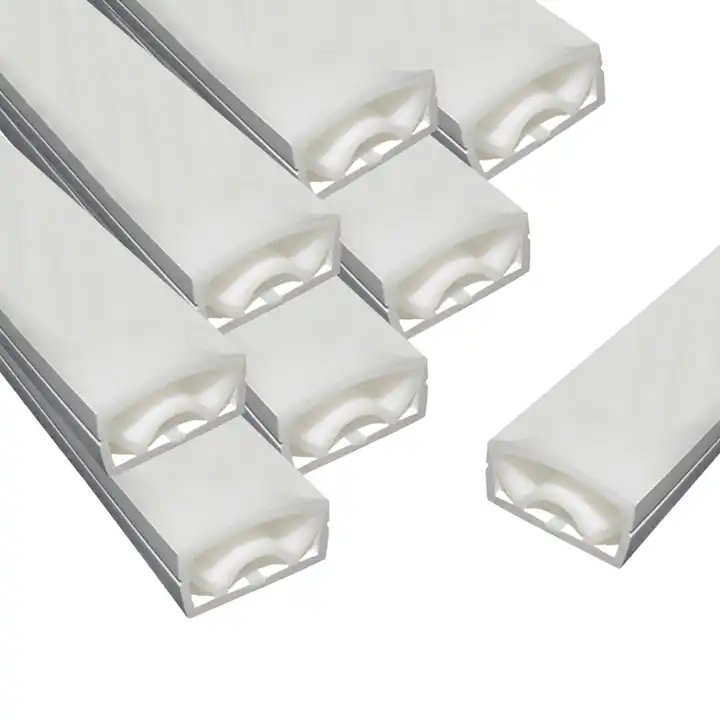

(automobile sealing strip series)

Innovation in Automobile Sealing Strip Series for Modern Vehicles

Contemporary automotive manufacturing demands precision sealing solutions that evolve with stricter environmental regulations and performance expectations. Modern sealing systems now integrate multiple functionalities including noise dampening, thermal regulation, and aerodynamic enhancement. Industry data reveals 47% of warranty claims relate directly to sealing failures, driving manufacturers toward advanced polymer compounds and structural designs.

The transition to electric powertrains has introduced new engineering challenges requiring sealing strip redesigns. Thermal management properties now rank equally with traditional waterproofing criteria, as battery compartments demand exacting temperature consistency. Automotive engineers increasingly collaborate with specialized suppliers early in prototyping stages to prevent costly redesigns during tooling phases.

Engineering Superiority in Sealing Solutions

Premium sealing systems incorporate seven critical performance characteristics unavailable in standard products. TPV (thermoplastic vulcanizate) formulations maintain flexibility across extreme temperature ranges from -50°C to 120°C while resisting ozone degradation. Dual-density extruded profiles combine rigid attachment sections with soft surface-contact edges, creating persistent sealing force without material fatigue.

Innovative flocking techniques create low-friction surfaces that slide effortlessly against window glass, reducing motor wear by 33% in testing. Integrated moisture channels within the cross-section profile redirect water away from critical components, solving the drainage issues common in economy-class seals. Noise reduction measurements show advanced EPDM formulations achieve up to 8dB better acoustic insulation than legacy materials.

Market Dynamics and Material Advancements

The global automotive sealing market reached $19.3 billion in 2023 with projected 6.2% CAGR through 2030. Leading OEMs now allocate 12-15% of component budgets specifically to sealing improvements. The material science revolution has yielded proprietary compounds with self-healing molecular structures that recover from minor impacts, significantly extending service life.

Recent breakthroughs include silicone-modified polymers that retain flexibility at extreme temperatures and graphene-enhanced EPDM that improves compression set resistance by 40%. Sustainability metrics show 83% of premium sealing materials now incorporate recycled content without performance compromise. Laboratory results demonstrate these advanced formulations maintain structural integrity beyond 500,000 door actuation cycles.

Manufacturing Capability Comparison

| Production Specialist | Annual Capacity (linear meters) | Material Certifications | Tooling Precision | Regional Coverage |

|---|---|---|---|---|

| Precision Sealing Solutions | 45 million | ISO/TS 16949, IATF | ±0.05mm tolerance | Global distribution |

| Global Rubber Tech | 28 million | ISO 9001 | ±0.08mm tolerance | North America/Europe |

| Advanced Polymer Engineering | 19 million | AS9100D, IATF | ±0.03mm tolerance | Asia-Pacific focus |

Leading factories invest approximately $7M annually in co-extrusion tooling upgrades to achieve microscopic dimensional accuracies. Production metrics reveal tier-one suppliers maintain defect rates below 0.03% through automated vision inspection systems integrated directly into extrusion lines.

Customization Capabilities

Specialized manufacturers offer complete profile redesign services beginning with 3D vehicle scanning to capture exact flange dimensions and curvature variations. Prototyping facilities utilize industrial-scale extruders capable of delivering functional samples within 72 hours of final design approval, accelerating development cycles.

Dedicated engineering teams manage over 200 variables across sealing system development including cross-section geometry, material specifications, clip spacing patterns, and critical interface zones. Production facilities maintain material inventories covering 17 color variants with custom color-matching available against OEM standards.

Dual-shore hardness construction allows precise zoning of material properties where complex geometries require varying compression forces. End-formed solutions are developed simultaneously with extrusion design to eliminate field installation challenges. Weather testing protocols simulate 10-year environmental exposure in accelerated chambers during validation phases.

Implementation Success Stories

A Scandinavian EV manufacturer integrated custom low-temperature sealing strips across door systems and panoramic roof assemblies, extending cold weather performance thresholds. Testing confirmed operational integrity at -42°C, enabling successful market entry into arctic regions. The comprehensive sealing solution reduced cabin noise measurements by 18% in independent wind tunnel evaluations.

South American bus manufacturers transitioned to specialized solar-reflective sealing systems that reduce thermal transmission by 34%, significantly decreasing air conditioning loads in equatorial climates. The formulation used incorporated ceramic microspheres within the polymer matrix to achieve the energy efficiency targets.

Aftermarket specialists developed vehicle-specific trunk sealing kits for multiple luxury models that resolved chronic water ingress issues. Installation data showed a 91% reduction in customer complaints related to trunk compartment leaks through precise dimensional mapping of pinch weld variations across model years.

Why Partner with a Leading Automobile Sealing Strip Series Exporter

Selecting an established exporter ensures comprehensive quality management throughout the supply chain. Top-tier facilities maintain vertically integrated manufacturing from compounding through secondary operations and final packaging. This control eliminates quality variations common with subcontracted processes and protects proprietary material formulations.

Logistical advantages emerge through direct relationships with global logistics providers, creating efficiencies that typically reduce transit times by 20%. Seasoned suppliers assist with regulatory documentation including country-specific material composition reports and automotive compliance certificates. Technical support extends beyond product delivery with dedicated engineering teams providing application assistance remotely during installation ramp-ups.

(automobile sealing strip series)

FAQS on automobile sealing strip series

Q: What are automobile sealing strip series products used for?

A: Automobile sealing strip series products seal gaps in vehicle doors, windows, and trunks. They prevent water, dust, and noise from entering the cabin while ensuring smooth operation of moving parts. These essential components enhance passenger comfort and vehicle longevity.

Q: Why choose your automobile sealing strip series factory?

A: Our factory utilizes advanced extrusion technology and automated quality control systems. We comply with ISO/TS 16949 automotive standards for precision manufacturing. This ensures reliable, OEM-grade sealing solutions with rigorous durability testing.

Q: What customization options do you offer for sealing strip series?

A: We customize profiles based on vehicle models, materials (EPDM, TPE, silicone), and colors. Special features like anti-pinch sensors or integrated drainage channels can be incorporated. Our engineering team develops solutions tailored to client specifications and regional climate demands.

Q: How does your company ensure export efficiency as an automobile sealing strip series exporter?

A: We maintain an export-ready inventory with HS-coded packaging for streamlined customs clearance. Our logistics network covers major ports with consolidated shipping options. Just-in-time production scheduling guarantees on-time delivery for international clients.

Q: What certifications do your automobile sealing strip series comply with?

A: Our products meet global standards including SAE J200, ISO 9001, and REACH regulations. Material certifications include UL, RoHS, and specific OEM automotive requirements. Continuous third-party audits validate our quality management systems.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025