Acrylic Heat Bender Tool-Type A-Hebei Pulongte|Precision&Innovation

Sep . 19, 2025 15:45 Back to list

Acrylic Heat Bender Tool-Type A-Hebei Pulongte|Precision&Innovation

The Acrylic Heat Bender Tool-Type A represents a significant advancement in the field of acrylic material processing. Designed for both industrial and DIY applications, this tool combines precision engineering with user-friendly features to deliver exceptional results. Whether you're manufacturing custom acrylic components or working on creative projects, the Acrylic Heat Bender Tool-Type A offers the versatility and reliability needed to achieve professional-grade outcomes.

Figure 1: Application of acrylic bending in decorative lighting design.

Product Overview and Core Features

The Acrylic Heat Bender Tool-Type A is a specialized device engineered to heat and shape acrylic sheets into complex forms. Its design emphasizes durability, efficiency, and ease of use, making it an ideal choice for professionals and hobbyists alike. The tool's key features include:

- High-Temperature Heating Elements: The device utilizes advanced heating technology to evenly distribute heat, ensuring consistent bending without warping or cracking.

- Adjustable Temperature Control: Users can customize the heating level based on the thickness and type of acrylic material, allowing for precise control over the bending process.

- Durable Construction: Built with high-quality materials, the tool is designed to withstand frequent use in demanding environments.

- Intuitive Design: The ergonomic handle and user-friendly interface reduce the learning curve, enabling even novice users to achieve professional results.

Figure 2: Integration of acrylic bending in 3D trim cap manufacturing.

Technical Specifications

| Feature | Description |

|---|---|

| Power Supply | 120V/60Hz (standard) or customizable for international use |

| Heating Elements | 300W ceramic heating rods with uniform heat distribution |

| Temperature Range | 100°C to 180°C (adjustable via digital thermostat) |

| Material Compatibility | Acrylic (PMMA), polycarbonate, and other thermoplastic sheets |

| Dimensions | 18.5" (L) x 6.5" (W) x 4.2" (H) |

| Weight | 4.8 lbs |

Applications and Use Cases

The versatility of the Acrylic Heat Bender Tool-Type A makes it suitable for a wide range of applications across industries. Some common use cases include:

- Architectural Design: Creating curved acrylic panels for partitions, skylights, and decorative elements.

- Industrial Manufacturing: Producing custom-shaped acrylic components for machinery, signage, and equipment housings.

- Consumer Goods: Crafting personalized acrylic products such as lampshades, display cases, and 3D trim caps (as seen in

).

). - Art and Craft Projects: Enabling artists and DIY enthusiasts to experiment with acrylic materials for unique creations.

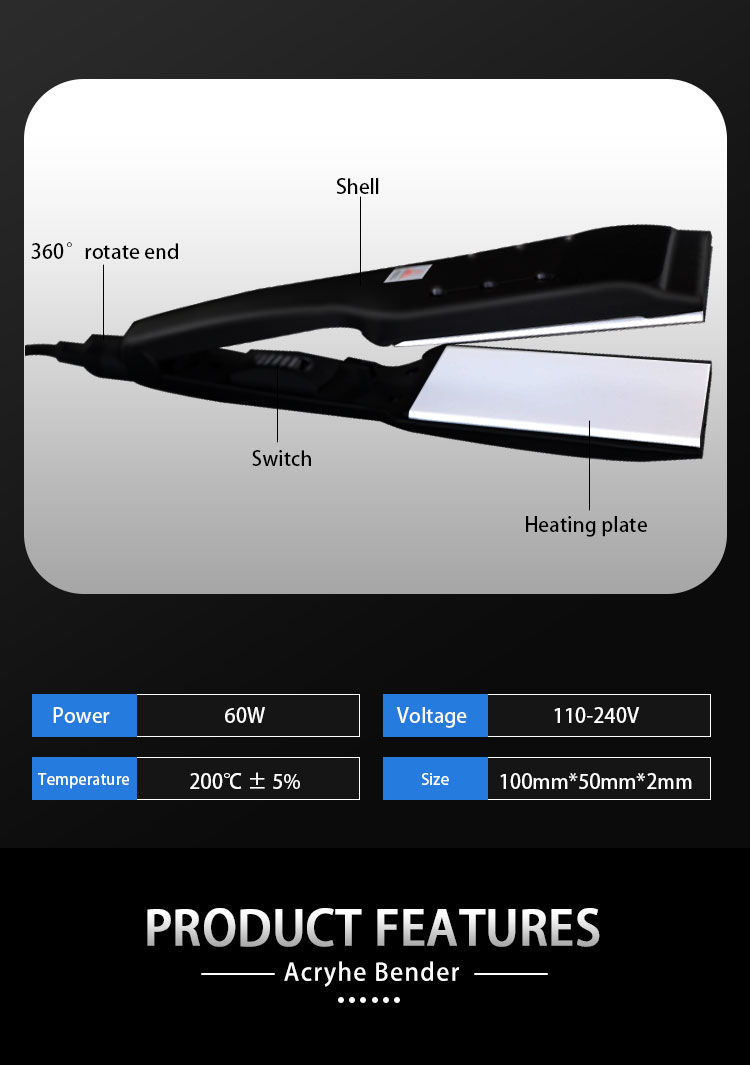

Figure 3: Detailed view of the Acrylic Heat Bender Tool-Type A.

Advantages of the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A stands out in the market due to its numerous advantages, including:

- Enhanced Precision: The tool's advanced heating system ensures accurate bending, minimizing material waste and rework.

- Time Efficiency: Compared to traditional methods, the Acrylic Heat Bender Tool-Type A significantly reduces the time required to shape acrylic materials.

- Cost-Effectiveness: By eliminating the need for complex machinery or outsourcing, the tool offers a cost-efficient solution for small-scale production and prototyping.

- Environmental Friendliness: The device's energy-efficient design reduces power consumption, aligning with sustainable manufacturing practices.

Figure 4: Application of the tool in manufacturing 3D metal acrylic trim caps.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

The Acrylic Heat Bender Tool-Type A is developed and manufactured by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., a leading company in the plastics and rubber industry. With years of experience in material processing, Hebei Pulongte has established itself as a trusted supplier of high-quality tools and components for industrial and commercial applications. The company's commitment to innovation and quality is evident in its product lineup, which includes a wide range of acrylic and thermoplastic processing solutions.

Figure 5: Manufacturing process of acrylic trim caps at Hebei Pulongte.

Industry Standards and Quality Assurance

Hebei Pulongte adheres to strict quality control measures to ensure that its products meet international standards. The Acrylic Heat Bender Tool-Type A is designed in accordance with NIST (National Institute of Standards and Technology) guidelines for precision manufacturing and material processing. NIST's research on thermoplastic materials and heating technologies has directly influenced the development of tools like the Acrylic Heat Bender Tool-Type A, ensuring that they deliver reliable performance and consistency.

According to NIST, "The accurate measurement and control of thermal processes are critical for the production of high-quality thermoplastic components. Tools that integrate advanced heating and temperature regulation mechanisms, such as the Acrylic Heat Bender Tool-Type A, play a vital role in achieving these standards" (NIST, 2025).

Figure 6: Hebei Pulongte's manufacturing facility.

Why Choose the Acrylic Heat Bender Tool-Type A?

When compared to alternative solutions, the Acrylic Heat Bender Tool-Type A offers several distinct advantages:

- Superior Heating Technology: Unlike conventional methods that rely on open flames or ovens, the tool's enclosed heating system ensures even heat distribution and reduces the risk of overheating.

- Customizable Settings: The ability to adjust temperature and pressure allows users to adapt the tool to different material types and project requirements.

- Compact and Portable: Its lightweight design makes it easy to transport and use in various workspaces, from workshops to on-site locations.

- Comprehensive Support: Hebei Pulongte provides detailed user manuals, technical support, and warranty services to ensure customer satisfaction.

Figure 7: Exporting the Acrylic Heat Bender Tool-Type A to global markets.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to the innovation and expertise of Hebei Pulongte Rubber and Plastic Technology Co., Ltd. By combining cutting-edge technology with user-centric design, this tool addresses the evolving needs of industries that rely on acrylic materials. Its precision, efficiency, and adaptability make it an indispensable asset for manufacturers, designers, and hobbyists alike.

For more information about the Acrylic Heat Bender Tool-Type A or to explore other products from Hebei Pulongte, visit their official website. Additionally, you can request a product specification sheet or price list for detailed insights.

References

NIST (National Institute of Standards and Technology). (2025). Thermoplastic Material Processing and Heating Standards. Retrieved from https://www.nist.gov.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025