Factory Hot Sale Banner Product PVC Profiles Strip wholesale

Oct . 12, 2025 10:55 Back to list

Factory Hot Sale Banner Product PVC Profiles Strip wholesale

PVC Banner Profiles Strip: What Buyers Really Need to Know in 2025

If you’re sourcing banner edging or frame inserts for signage lines, you’ve probably seen a dozen similar listings. Still, the Factory Hot Sale Banner Product PVC Profiles Strip wholesale from Pulongte lands on spec sheets more often than most. I visited their origin site in Xiangjiang Street South, Jinggangshan Road west, Qinghe County, Xingtai City, Hebei Province a while back—busy extrusion lines, tidy QA corner, and, to be honest, better color consistency than I expected.

Where it’s used (and why it’s trending)

These PVC profile strips edge and reinforce banners, POP displays, and lightbox frames. Outdoor retailers like the UV-resistant options; exhibition contractors like the tight tolerances for quick assembly. Demand is rising in OOH billboards, mall wayfinding, and even truck tarp trims. It seems that shorter campaign cycles push buyers toward fast-turn, color-stable PVC over aluminum for cost and speed.

Key advantages reported by buyers

- Stable fit: tight extrusion tolerances reduce banner slop.

- Color fidelity: ΔE typically ≤ 1.0 on standard whites and blacks, lab-verified.

- Outdoor durability: UV packages available; fewer cracks in cold snaps.

- Cost-effective vs. aluminum frames for mid-term campaigns.

Process flow and materials (quick but real)

Material: PVC resin (K≈57–70), Ca-Zn stabilizers (lead-free), impact modifiers, internal/external lubricants, optional UV absorbers/antioxidants. Method: single- or co-extrusion with inline calibration and water-cooling. Options include soft-lip co-extrusion for grip. QC: hardness (ISO 868), tensile/elongation (ISO 527 / ASTM D638), color (ΔE), dimensional check (±0.15 mm typical), and QUV aging (ASTM G154). Service life: around 3–5 years outdoor, 8–10 years indoor—real-world use may vary by climate and color.

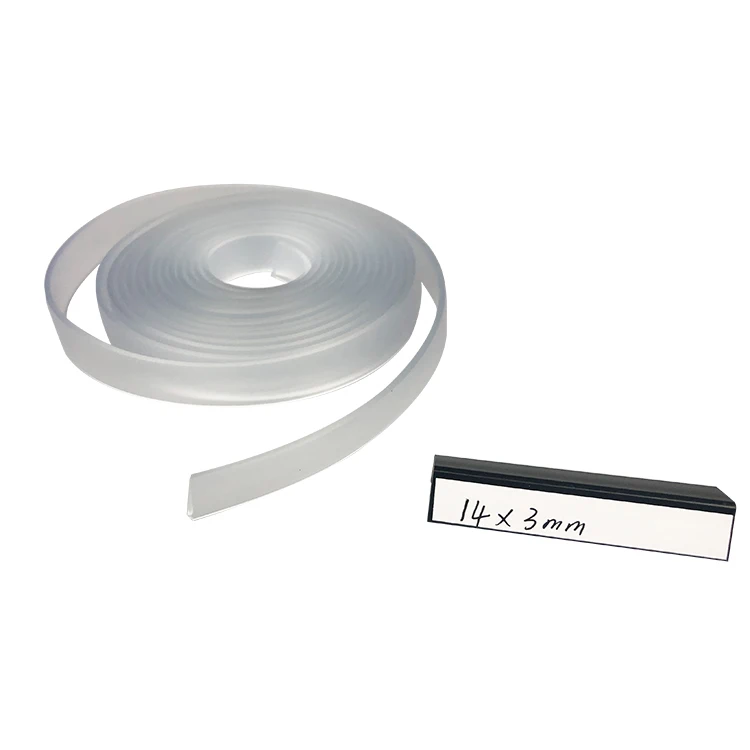

Typical product specs

| Profile width × thickness | 10–40 mm × 0.8–3.0 mm (custom) |

| Shore hardness | A85–A95 (soft lip optional A70); rigid options D70–D78 |

| Tensile strength | ≥ 12 MPa (ISO 527) |

| Elongation at break | ≥ 250% (ASTM D638) |

| Density | ≈ 1.35–1.45 g/cm³ |

| Temp. range | -20°C to +60°C standard; low-temp formula optional |

| Flammability | UL 94 V-0 optional formulation |

| Compliance | RoHS & REACH (SVHC) compliant |

Vendor snapshot (why factories aren’t equal)

| Vendor | Lead time | MOQ | Certs | Tooling | Customization |

|---|---|---|---|---|---|

| Pulongte (Factory) | 7–15 days | ≈ 1,000 m/size | ISO 9001, RoHS/REACH, UL 94 (optional) | Low, in-house die shop | Color, durometer, co-extrusion, emboss |

| Trader A | 20–30 days | 3,000 m/size | Basic RoHS | Medium | Limited color range |

| Workshop B | 10–20 days | 1,500 m/size | No third-party certs | Low | Basic thickness only |

Real usage: two quick case notes

Factory Hot Sale Banner Product PVC Profiles Strip wholesale was specified by an EU outdoor retailer for 1,200 lightbox frames. After 1,000 hours of QUV testing (ASTM G154), color shift on white profiles measured ΔE 0.8—well below their 1.5 threshold. Another job in the GCC region swapped aluminum trims for PVC to reduce weight; installation time reportedly fell by ≈18% because the co-extruded soft lip gripped the fabric without rework.

Customization tips

- Ask for ΔE reports against your Pantone—batch to batch.

- If winter installs matter, request low-temperature impact modifier.

- Consider UL 94 V-0 for mall interiors and transit hubs (often mandated).

- Co-extruded soft lips help with fast banner tensioning—less scrap.

Customer feedback: “Edges stayed snug after three show cycles,” a trade-fair contractor told me; “surprisingly clean cuts with standard shears,” said another.

For most signage buyers who need reliable tolerances without boutique pricing, Factory Hot Sale Banner Product PVC Profiles Strip wholesale strikes that practical balance. Not glamorous, but it does the job—day in, day out.

References

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025