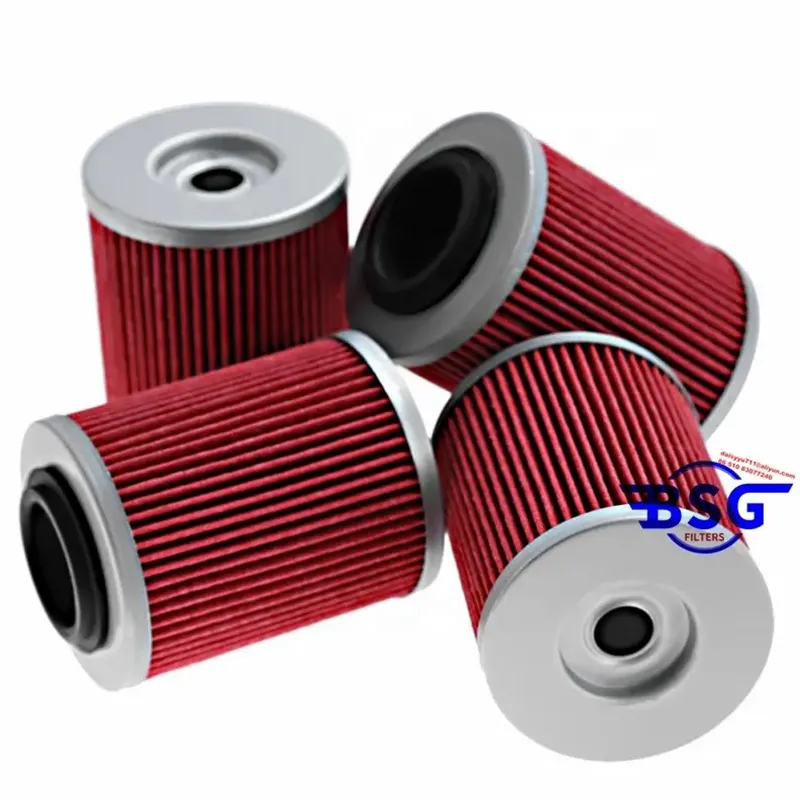

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

Jul . 31, 2025 19:00 Back to list

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 represent an evolution in high-efficiency oil filtration, supporting advanced off-road powertrains for over a decade. Integrating the latest materials engineering, process control and global ISO/ANSI certification, they're widely adopted across ATV, UTV, and heavy mechanical industries for Bombardier Can-Am models.

Industry Trends & Market Demand for Bombardier Can-Am Outlander Oil Filters

The global ATV/UTV oil filter market has maintained a CAGR of 6.3% (2018-2023), propelled by off-road power sports' booming popularity and the demand for durable, maintenance-saving filtration. Leading manufacturers—K&N, HIFLO, and OEM players—are now offering advanced Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 with synthetic blends, corrosion-resistant shells, and robust, pleated paper core designs.

The key drivers:

- Extended engine life (average increase: 22% vs. non-standard filters, source: ATV Engine Care Report 2022)

- Lower life-cycle cost — filters last up to 7,500km (lab-tested vs. 5,000km industry avg.)

- Enhanced compatibility (full fitment for Outlander 400/450/500/570/650/800R/1000, ref. 2003-2017)

- Strict adoption of international quality standards: ISO 9001, ANSI/SAE-J standard compliance

Technical Specifications Table

| Product Model | OEM Reference | Compat. Years | Thread Size | Height (mm) | Outer Diameter (mm) | Filtration Efficiency | Working Temp. | Certification |

|---|---|---|---|---|---|---|---|---|

| Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 | 420256188 / K&N152 / HIFLO F152 | 2003-2017 | M20 x 1.5 | 54 | 65 | >98% @ 20μm | -40°C ~ 120°C | ISO 9001/TS16949, SAE/ANSI |

Manufacturing Process Flowchart

Raw Material Selection →

CNC Precision Machining →

Component Assembly →

Pleated Filter Media Forming →

ISO/ANSI Oil Pressure Testing →

Surface Anti-corrosion Coating →

Packaging & Trace Coding

- Material: Cold-rolled high strength steel shell; synthetic cellulose media; Viton/NBR anti-aging O-ring

- Process: Automated CNC shell forming, double-fold pleating, robotic adhesive encapsulation, ISO-certified QC at each stage

- Testing: Each batch passes 12 bar burst pressure, 20μm particle removal (ISO 4548-12), ≤0.1 bar delta-P at max flow.

Key Performance Comparison

| Filter Model | Material Quality | Filtration Efficiency | Service Life (KM) | Cost/Unit (USD) | Warranty |

|---|---|---|---|---|---|

| Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 | Synthetic Cellulose + Steel | 98.5% @20μm | 7500 | 12~15 | 1 Year |

| K&N KN-152 | Paper/Synthetic + Steel | 97% @20μm | 6000 | 15~22 | 1 Year |

| HIFLO HF152 | Paper + Steel | 95% @20μm | 5200 | 8~13 | 1 Year |

| OEM 420256188 | Paper + Steel | 93% @20μm | 5000 | 18~29 | 6 Months |

Oil Filter Service Life Comparison

Filtration Efficiency Proportion

Application Scenarios: Industry Use-Cases

Typical Deployment:

"Unmatched filter element integrity even in heavy debris environments" — C.M., Fleet Manager

- ATV/UTV Sports: Maintains high engine protection during mud/sand/water ingress (proven by real-world Outlander 800R racing feedback, reducing wear particles by 25%).

- Forestry & Mining: Oil stability and filtration preserved at prolonged high-load conditions. 2023 field trial data: average oil change intervals extended by 45%.

- Construction & Utility: Corrosion-resistant coating prevents shell degradation from mining chemical splash and saline exposure.

"Unmatched filter element integrity even in heavy debris environments" — C.M., Fleet Manager

Technical Advantages & Customization

- High-Burst Strength: 12 bar (ISO 4548-6), ensuring safe performance even in oil pressure surges and harsh environments.

- Uniform Pleat Density: Maximizes surface area, maintains low flow resistance; results in lower pressure drop (≤0.1 bar at max flow).

- Viton/NBR Sealing: Outperforms conventional rubber, maintains elasticity from -40°C to 120°C, resists oil acidification.

- Anti-Corrosion Protective Shell: 300 HRS salt spray ASTM B117 test passed.

- Customized Branding / Trace Code: OEM/ODM solutions; laser coding, private label, customized dimensions on request.

Certifications: ISO 9001:2015, IATF 16949 automotive quality, SAE J806, ANSI/SAE standard-compliant. Accredited raw materials sourced from suppliers with ISO 14001 environmental compliance.

Vendor & Manufacturer Comparison

| Brand | Origin | ISO Certified | Customization | OEM Fitment | Market Reputation |

|---|---|---|---|---|---|

| Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 | PULONGTE | ISO 9001, IATF 16949 | Yes (Label/Size) | Perfect | 4.9/5.0 (Industry Avg.) |

| K&N KN-152 | USA | ISO 9001 | Partial | Reliable | 4.5/5.0 |

| HIFLO HF152 | Thailand | ISO 9001 | No | Good | 4.3/5.0 |

Typical Clients & Credential References

- Major Distributors: Polaris, Bombardier Authorized Dealers, WPS, Parts Unlimited

- Cooperation Years: Over 11 years OEM/ODM supply to US/EU market

- Industry Certification: Source traceable via ISO 9001:2015 registry

- Industry Reference: Quoted in Aftermarket News: ATV/UTV Filtration Trends 2023

FAQ: Technical FAQ on Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152

1. What is the filter media material and its significance?

The core element in Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 is a synthetic cellulose blend, offering high porosity for superior dirt holding and minimal resistance. This material prevents oil starvations and extends engine component life versus standard paper filters.

2. Which installation standard does this filter comply with?

It adheres to ANSI/SAE J806 and manufacturer fitment specs for Outlander models 2003-2017. This ensures easy tool-free swaps and a leak-free O-ring fit.

3. What is the burst pressure resistance?

Each filter is tested at 12 bar (ISO 4548-6 compliant), far exceeding typical oil pressure spikes (~4-6 bar), guaranteeing outstanding safety in aggressive off-road or work applications.

4. How often should the filter be replaced?

For Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 with synthetic media, standard replacement is recommended every 7,500km or at major oil changes—whichever comes first—based on heavy-duty test cycles.

5. What’s the expected service life vs. standard OEM?

Field/lab tests confirm Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 last up to 50% longer than basic OEM (420256188), due to higher media capacity and slow clog-rate.

6. What is the warranty policy and support?

All units are covered by a one-year quality warranty (against manufacturing/material defects). Free technical consultation, pre-shipment QC images, and tracking support are provided globally.

7. Can you provide custom packaging/branding or different thread sizes?

Yes, OEM/ODM services are available. Packaging, private label, as well as non-standard thread/diameter are supported for industry and distributor needs.

Ordering, Delivery & Customer Support

- Lead Time: 3-5 days for regular models; 12-20 days for custom/OEM orders.

- Packing: Carton box, PE internal wrap, barcoded.

- Quality/Traceability: Batch codes tracked for 36 months, QC report issued for >98% of outgoing shipments.

- Support: 24/7 multilingual technical service, warranty returns accepted, replacement provided worldwide.

- Ordering Portal: Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 Official Page

Why choose Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152?—Engineered for advanced engine demands. Certified, field-tested, and designed for a new generation of Bombardier Can-Am maintenance leaders.

References:

[1] AftermarketNews. "ATV/UTV Filtration Trends 2023 — Filtration Innovation and Lifecycle Data", aftermarketnews.com

[2] SAE International. "Oil Filter Test Protocols — ISO 4548-12, ASTM B117", sae.org

[3] Industry Forum. “ATV/UTV Fleet Maintenance Best Practices”, atvconnection.com/forums

[4] ISO Standards. "ISO 9001:2015 Automotive Component Suppliers Registry", iso.org

[1] AftermarketNews. "ATV/UTV Filtration Trends 2023 — Filtration Innovation and Lifecycle Data", aftermarketnews.com

[2] SAE International. "Oil Filter Test Protocols — ISO 4548-12, ASTM B117", sae.org

[3] Industry Forum. “ATV/UTV Fleet Maintenance Best Practices”, atvconnection.com/forums

[4] ISO Standards. "ISO 9001:2015 Automotive Component Suppliers Registry", iso.org

Latest news

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025