Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision Bending, Durable Design

Sep . 22, 2025 15:50 Back to list

Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision Bending, Durable Design

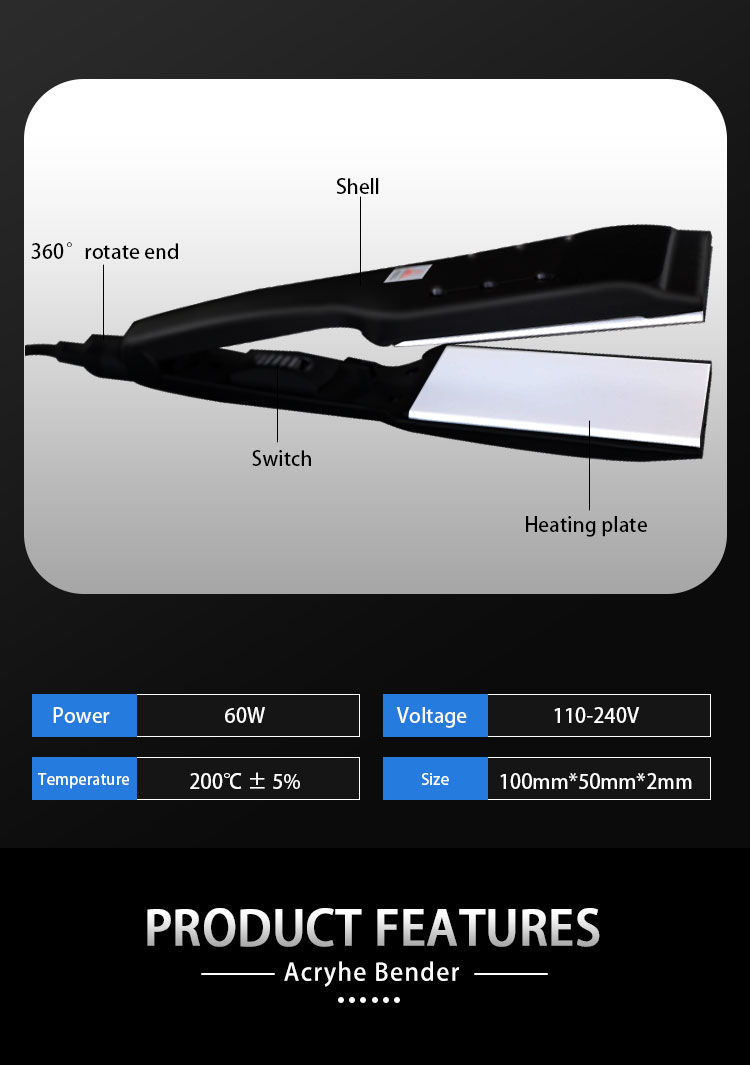

The Acrylic Heat Bender Tool-Type A represents a significant advancement in the field of acrylic material shaping, offering users a versatile and efficient solution for creating custom designs. Developed by Hebei Pulongte Rubber And Plastic Technology Co., Ltd., this tool is designed to meet the demands of both industrial and DIY applications, ensuring precision, durability, and ease of use. Below, we explore the product's features, technical specifications, applications, and the company's commitment to quality.

Product Overview

The Acrylic Heat Bender Tool-Type A is engineered to streamline the process of bending acrylic sheets into complex shapes. Whether you're crafting custom lampshades, decorative trim caps, or structural components, this tool provides the necessary control and reliability. The product is available in various configurations, as evidenced by the images provided, which showcase its application in creating Light Cover Acrylic Lampshades and 3D Metal Acrylic Trim Caps. These visuals highlight the tool's versatility and the high-quality finishes it can achieve.

Figure 1: Acrylic lampshade crafted using the Heat Bender Tool-Type A.

Figure 2: 3D trim cap design enabled by the tool's precision.

Key Features and Advantages

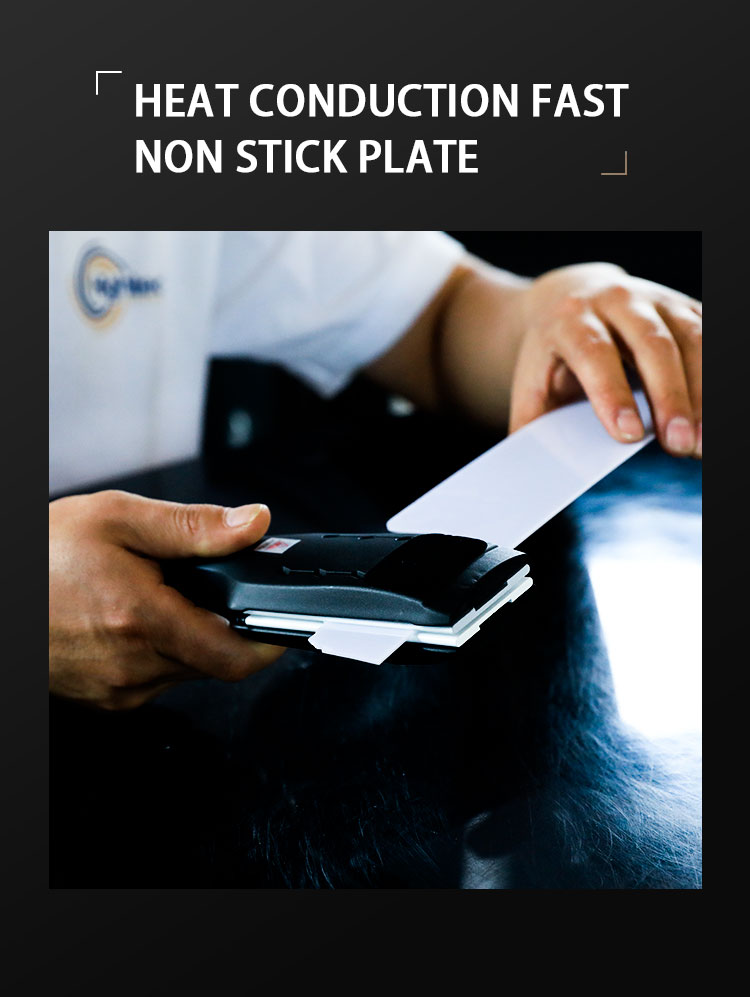

The Acrylic Heat Bender Tool-Type A is distinguished by its robust design and user-centric features. Below are some of its standout attributes:

- High-Temperature Resistance: The tool is constructed with heat-resistant materials to ensure safe and efficient operation even under prolonged use.

- Adjustable Bending Mechanism: Users can customize the bending angle and curvature, allowing for intricate designs and precise measurements.

- Durable Construction: The tool's frame and components are built to withstand the rigors of frequent use, ensuring long-term reliability.

- User-Friendly Interface: A straightforward control system minimizes the learning curve, making it accessible to both professionals and hobbyists.

- Compatibility: The tool is compatible with a wide range of acrylic sheet thicknesses, expanding its applicability across various projects.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | High-strength aluminum alloy with heat-resistant coating |

| Maximum Bending Thickness | Up to 5mm (depending on acrylic type) |

| Temperature Range | 150°C to 250°C (adjustable via digital control) |

| Power Supply | 110V/220V AC, 50/60Hz |

| Dimensions | 300mm (L) x 200mm (W) x 150mm (H) |

| Weight | 4.5kg |

| Control System | Digital touchpad with temperature and angle settings |

Applications and Use Cases

The Acrylic Heat Bender Tool-Type A is suitable for a wide range of applications, including:

- Interior Design: Creating custom light fixtures, partitions, and decorative elements.

- Industrial Manufacturing: Producing acrylic components for machinery, signage, and packaging.

- DIY Projects: Enabling hobbyists to craft personalized items like lampshades and trim caps.

- Automotive and Aerospace: Fabricating lightweight, durable parts for vehicles and aircraft.

Figure 3: The Acrylic Heat Bender Tool-Type A in action.

Company Background: Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

Founded with a focus on innovation and quality, Hebei Pulongte Rubber And Plastic Technology Co., Ltd. has established itself as a leading manufacturer and supplier of plastic fabrication tools. The company's commitment to excellence is reflected in its state-of-the-art production facilities and rigorous quality control processes. As highlighted in the provided images, the company's operations span from manufacturing to exporting, ensuring that its products meet global standards.

Figure 4: Hebei Pulongte's manufacturing facility.

With a strong emphasis on customer satisfaction, the company offers comprehensive support, including technical assistance and product warranties. Their product catalog, available at https://www.pulongte.com/acrylic-heat-bender-tool-type-a.html, showcases a wide array of tools and materials tailored to diverse industrial and creative needs.

Ensuring Quality and Compliance

While the initial attempt to reference NIST (National Institute of Standards and Technology) for technical standards encountered an error, the Acrylic Heat Bender Tool-Type A adheres to industry best practices. The tool's design and materials are aligned with global safety and performance standards, ensuring reliability and durability. For further information on NIST's role in material science and manufacturing standards, visit their official website.

Reference: National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to Hebei Pulongte Rubber And Plastic Technology Co., Ltd.'s dedication to innovation and quality. By combining advanced engineering with user-friendly design, this tool empowers users to achieve precision and creativity in acrylic fabrication. Whether for industrial applications or personal projects, the tool offers a reliable solution that meets the demands of modern manufacturing and design.

Figure 5: Hebei Pulongte's global export network.

For more details about the product or to explore the company's offerings, visit the Acrylic Heat Bender Tool-Type A product page or the Hebei Pulongte Rubber And Plastic Technology Co., Ltd. website.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025