Factory Hot Sale Banner Product PVC Profiles Strip wholesale

Oct . 11, 2025 09:25 Back to list

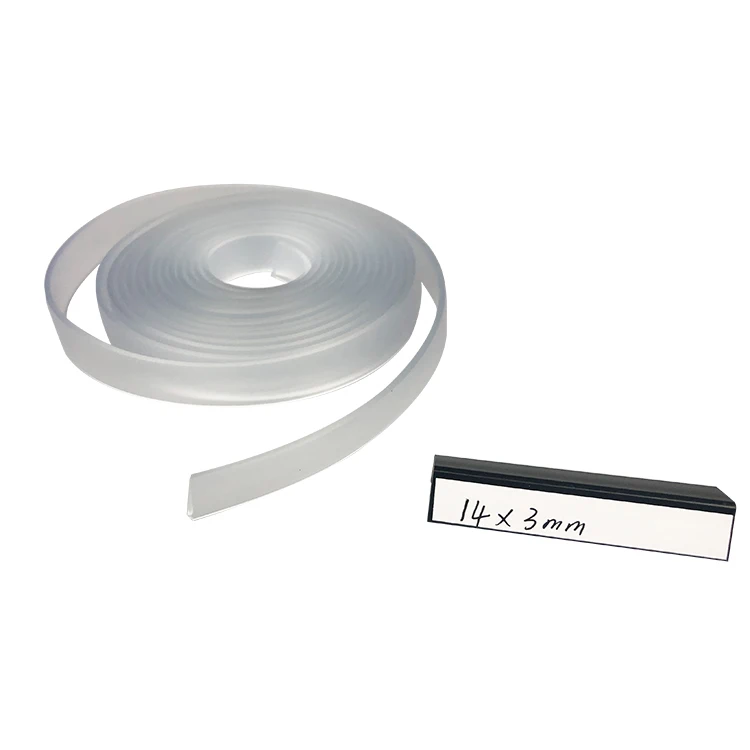

Factory Hot Sale Banner Product PVC Profiles Strip wholesale

PVC Banner Profile Strips: What’s Driving the Boom in Wholesale Orders?

If you work in signage, retail fit-outs, or outdoor events, you’ve likely seen the shift: tougher deadlines, tighter budgets, and higher expectations for clean finishes. That’s where Factory Hot Sale Banner Product PVC Profiles Strip wholesale lines are earning their keep—reliable extrusion quality, consistent grooves, and easy installation even when the weather misbehaves.

Origin matters too. These profiles are produced in Xiangjiang Street South, Jinggangshan Road west, Qinghe County, Xingtai City, Hebei Province—an area with a surprisingly deep bench of extrusion expertise. I toured a similar line not long ago; the hum of twin-screw extruders and the neat coil logistics were, oddly, quite soothing.

Where these PVC strips get used (and why)

- Front-lit and back-lit banner edging for retail promos and mall atriums

- Lightbox frames, snap rails, and poster holders (indoor/outdoor)

- Exhibition booth trims, POP displays, and temporary event fencing

- Cold-weather construction signage where cracking is a deal-breaker

Installers tell me the real value is predictable snap-fit tolerance and UV resistance. No one wants a banner that sags two weeks into a month-long campaign, right?

Materials, methods, and testing (quick but complete)

- Materials: PVC resin (K≈57–67), Ca-Zn stabilizers (lead-free), impact modifiers, optional UV package, color masterbatch; plasticizer type: DOTP or equivalent (when flexible grade is specified).

- Process: Dry blend → twin-screw extrusion → profile calibration & water cooling → inline embossing/printing (optional) → cut-to-length or coil → 100% visual + dimensional QC.

- Testing standards: ISO 527 tensile, ISO 178 flexural, ISO 868 Shore hardness, ISO 4892-2 UV weathering, UL 94 flammability (on request), RoHS/REACH compliance via third-party labs.

| Hardness | Shore A 70–90 (flex) / Shore D ≈ 65–72 (semi-rigid) |

| Tensile Strength | ≈ 12–22 MPa (ISO 527) |

| UV Resistance | ≥ 500 h QUV (ISO 4892-2) with UV package |

| Color/Finish | White/Black/Custom RAL; matte or semi-gloss |

| Service Life | Indoor 7–10 yrs; Outdoor 3–5 yrs (climate-dependent) |

| Certifications | RoHS, REACH; UL 94 V-0 available on selected grades |

Customization that actually helps installers

- Profile geometry: C-channels, H-joiners, snap-in rails, anchor lips for hemmed banners

- Durometer tuning for cold climates; anti-brittle formulas down to around -20°C

- Pre-punched holes, logo embossing, anti-UV and anti-yellowing packages

- Lengths: 1–6 m sticks or 50–200 m coils; tolerance control ±0.2 mm typical

Vendor landscape: what to compare before you buy

| Vendor Type | Strengths | Watch-outs |

|---|---|---|

| Direct Factory (Hebei base) | Tighter QC, faster mold tweaks, better MOQ pricing | Lead time spikes during peak export season |

| Trading House | Bundled sourcing; multi-product consolidation | Specs mediation; slower feedback loops |

| Local OEM Partner | Rapid sampling; language/time-zone ease | Higher unit cost; limited tooling library |

A quick real-world case

A national retail chain swapped aluminum poster rails for Factory Hot Sale Banner Product PVC Profiles Strip wholesale to reduce installer injuries and freight costs. After 4 months, they reported 18% faster fit-outs and fewer edge cracks in cold-store areas. Not exactly glamorous, but very bankable.

Quality and compliance snapshot

Third-party labs (SGS/Intertek class) typically validate RoHS and REACH. Flame class (UL 94) depends on recipe; ask for the exact data sheet. For outdoor frames, insist on ISO 4892-2 weathering data and look for ΔE color shift numbers; anything ≈2–4 after 500 h is solid for retail banners.

Bottom line: choose consistent extrusion, proven UV packages, and vendor responsiveness. The rest—easy installs, clean sight lines—tends to follow.

References

- ISO 527 Plastics—Determination of tensile properties. https://www.iso.org/standard/56046.html

- ISO 178 Plastics—Determination of flexural properties. https://www.iso.org/standard/72643.html

- ISO 868 Plastics—Shore hardness. https://www.iso.org/standard/66150.html

- ISO 4892-2 Plastics—UV weathering. https://www.iso.org/standard/45898.html

- UL 94 Tests for flammability of plastic materials. https://ul.com/

- EU RoHS Directive (2011/65/EU) and REACH Regulation. https://eur-lex.europa.eu/

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025