High-Quality Sponge Door Seals Durable & Custom Solutions

May . 07, 2025 19:44 Back to list

High-Quality Sponge Door Seals Durable & Custom Solutions

- Overview of sponge seal

applications and industry relevance - Technical advantages: Material durability and performance metrics

- Manufacturer comparison: Key players in sponge door seal production

- Custom solutions: Tailored sponge door seal designs for specific industries

- Case studies: Real-world applications across commercial and residential sectors

- Quality assurance: Testing standards and compliance certifications

- Future trends: Innovations in sponge door seal technology

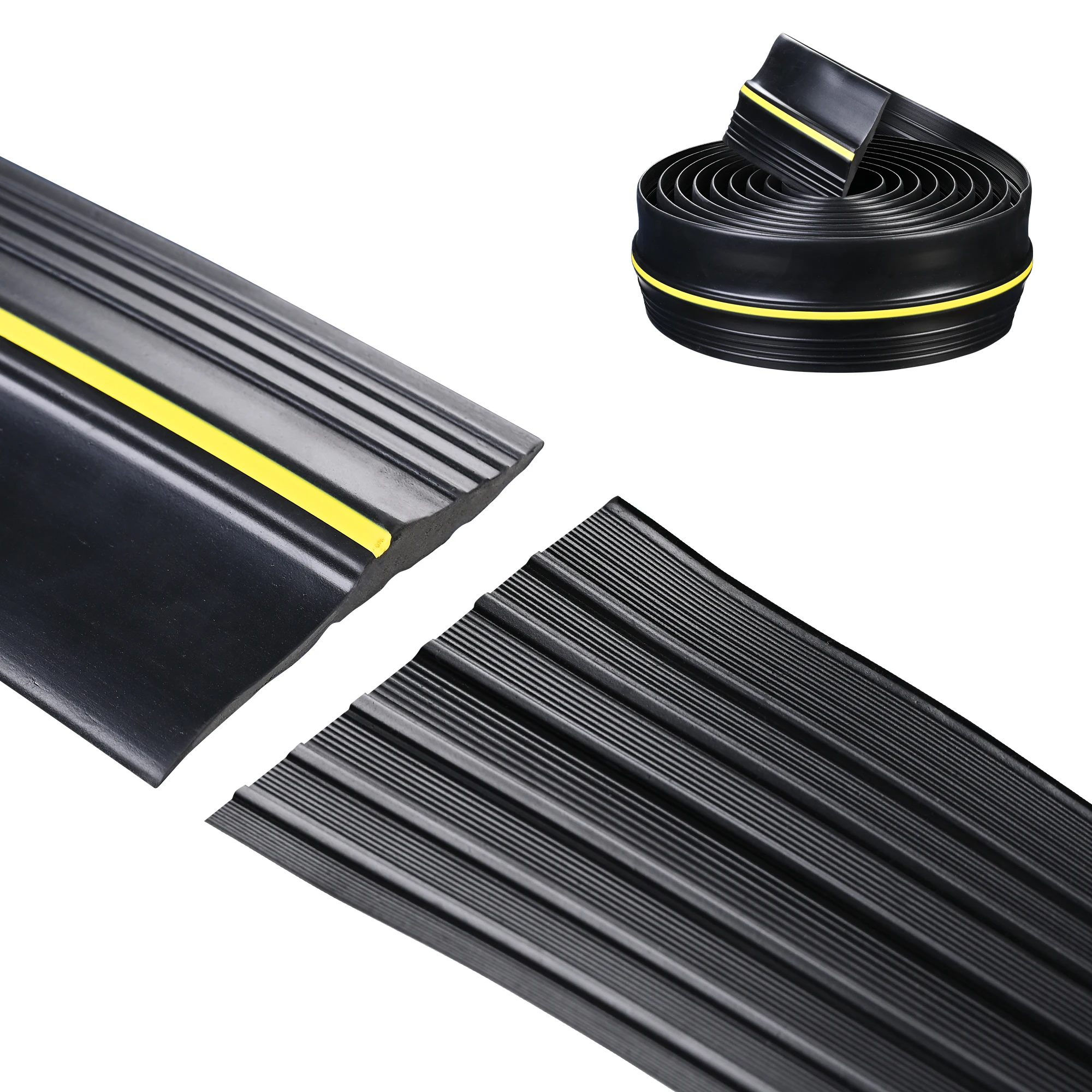

(sponge seal)

Understanding Sponge Seal Solutions for Modern Infrastructure

Sponge seals, particularly sponge door seals, play a critical role in enhancing energy efficiency and noise reduction in buildings. These components are engineered to fill gaps between doors and frames, preventing air leakage and moisture ingress. Leading sponge door seal manufacturers prioritize materials like EPDM, silicone, and polyurethane, which offer flexibility and resilience under varying temperatures (-40°C to 120°C). According to industry reports, buildings using high-quality sponge seals reduce HVAC energy consumption by up to 18%, underscoring their environmental and economic impact.

Technical Superiority in Material and Design

Advanced sponge seals incorporate closed-cell structures to resist compression set, maintaining a 90% recovery rate after 10,000 compression cycles. Compared to traditional rubber seals, sponge variants demonstrate 30% higher thermal insulation and 50% improved acoustic dampening. Manufacturers leverage precision extrusion technology to achieve tolerances as tight as ±0.2mm, ensuring seamless integration with door systems. Third-party testing data reveals that premium sponge door seals withstand UV exposure for 5,000+ hours without degradation.

Manufacturer Competitiveness Analysis

| Manufacturer | Production Capacity | Customization Lead Time | Industry Certifications |

|---|---|---|---|

| SealTech Industries | 8M linear meters/month | 10-14 days | ISO 9001, ASTM E283 |

| PolySeal Solutions | 5.5M linear meters/month | 15-20 days | UL Fire Rating, REACH |

| ElastoSeal Works | 3M linear meters/month | 25-30 days | ISO 14001, RoHS |

Bespoke Engineering for Specialized Requirements

Top-tier sponge door seal factories now offer parametric design services, enabling clients to specify density (20-120 kg/m³), hardness (10-80 Shore A), and flame-retardant additives. For pharmaceutical cleanrooms, antimicrobial-infused seals reduce bacterial growth by 99.7%. Automotive applications utilize conductive sponge seals with EMI shielding effectiveness of 60-90 dB. Custom tooling capabilities allow for asymmetrical profiles matching arched or sliding door geometries.

Performance Validation Through Case Studies

A hospital retrofit project in Germany achieved 42% noise reduction in MRI rooms using triple-layered sponge seals. In cold storage facilities, Arctic-grade seals maintained consistent performance at -55°C, reducing frost buildup by 65% compared to standard models. Residential complexes in coastal regions reported 80% fewer corrosion incidents after switching to salt-resistant sponge door seals with enhanced polymer blends.

Compliance and Testing Protocols

Reputable sponge door seal service providers adhere to EN 14351-2 for air permeability and EN 12207 for watertightness. Accelerated aging tests simulate 20 years of service life through 500 thermal shock cycles (-30°C to 70°C). Independent lab verifications confirm VOC emissions below 0.05 mg/m³, meeting LEED v4.1 criteria for indoor air quality.

Advancing Sponge Seal Technology for Sustainability

Emerging developments include bio-based sponge materials derived from recycled EPDM (45% post-industrial content) and self-healing polymers that repair minor abrasions autonomously. Smart seals with embedded IoT sensors now monitor compression loss in real-time, triggering maintenance alerts when seal efficiency drops below 85%. These innovations position sponge door seals as pivotal components in achieving net-zero building targets by 2030.

(sponge seal)

FAQS on sponge seal

Q: What are the key advantages of sourcing sponge door seals from a specialized manufacturer?

A: Specialized manufacturers offer tailored solutions, high-quality materials like EPDM or silicone, and compliance with industry standards, ensuring durability and optimal sealing performance.

Q: How to identify reliable sponge door seal factories?

A: Look for factories with certifications (e.g., ISO), proven production capabilities, and client testimonials. Transparent communication about customization and bulk order support is also critical.

Q: What services do sponge door seal providers typically offer?

A: Reputable providers offer design consultation, custom die-cutting, prototyping, and after-sales support to meet specific application needs, such as thermal insulation or noise reduction.

Q: Can sponge door seals be customized for unique door dimensions?

A: Yes, most manufacturers provide custom sizing, shape adjustments, and material selection to fit irregular door designs while maintaining sealing efficiency.

Q: What industries commonly use sponge door seals?

A: They are widely used in HVAC systems, automotive manufacturing, industrial machinery, and commercial buildings for weatherproofing, dust prevention, and energy efficiency.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025