Top Window Seal Strip Adhesive Companies - Durable & Reliable

Aug . 11, 2025 10:20 Back to list

Top Window Seal Strip Adhesive Companies - Durable & Reliable

The Crucial Role of Adhesive Seal Strips in Modern Industries

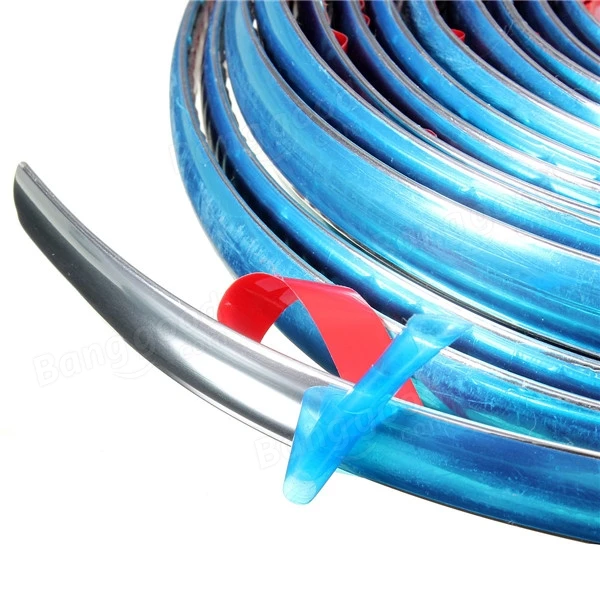

In diverse industrial sectors, the integrity and performance of sealants are paramount for efficiency, safety, and longevity. Among these, adhesive seal strips stand out for their versatility and robust bonding capabilities. These engineered components play a critical role in preventing leakage, reducing noise, and providing protection against environmental factors. Navigating the landscape of window seal strip adhesive companies is essential for procuring solutions that meet stringent technical specifications and application demands. Our focus extends to a comprehensive understanding of the manufacturing processes, technological advancements, and the diverse applications where these specialized products excel, including illustrative examples such as our own pvc chrome car decoration strip with self adhesive tape, which embodies the precision and durability expected from leading manufacturers.

The demand for high-performance adhesive solutions is constantly evolving, driven by innovations in automotive design, construction methodologies, and consumer electronics. As a result, the capabilities of a competent window seal strip adhesive company are defined not just by their product range but also by their research and development prowess, ensuring their offerings can withstand increasingly challenging operational environments, from extreme temperatures to chemical exposure.

Industry Trends and Technological Evolution in Adhesive Strips

The market for window seal strip adhesives is experiencing robust growth, propelled by advancements in material science and increasing regulatory emphasis on energy efficiency and noise reduction. Key trends include the development of eco-friendly, low-VOC (Volatile Organic Compound) adhesives, a shift towards more durable and weather-resistant polymers like EPDM (Ethylene Propylene Diene Monomer) and advanced PVC compounds, and the integration of smart manufacturing processes. Leading window seal strip adhesive manufacturers are focusing on enhanced adhesion properties across diverse substrates, improved UV and ozone resistance, and superior thermal insulation capabilities to meet the demanding requirements of modern applications.

Furthermore, the rise of electric vehicles and smart buildings necessitates seals with excellent electromagnetic shielding properties and acoustic dampening, pushing the boundaries for material innovation. The competitive landscape among window seal strip adhesive suppliers is driving continuous improvement in product performance and cost-effectiveness, fostering a market environment where innovation and technical expertise are paramount.

Detailed Manufacturing Process of Adhesive Seal Strips

The production of high-quality adhesive seal strips by top window seal strip adhesive factories involves a sophisticated multi-stage process, ensuring precision and consistent performance. This typically begins with the careful selection of raw materials, primarily polymers such as PVC, EPDM, or TPE (Thermoplastic Elastomer), chosen for their flexibility, durability, and resistance to environmental factors.

Core Manufacturing Stages:

- Material Compounding: Raw polymers are mixed with various additives like plasticizers, stabilizers, colorants, and foaming agents in precise ratios. This step is crucial for achieving the desired physical properties such as Shore hardness, flexibility, and UV resistance.

- Extrusion/Co-extrusion: The compounded material is fed into an extruder where it is heated and forced through a die to create the desired profile of the seal strip. Co-extrusion allows for the creation of multi-material profiles, such as a rigid base with a softer sealing lip, optimizing both structural integrity and sealing effectiveness.

- Surface Treatment & Adhesive Application: The extruded strip's bonding surface is often pre-treated (e.g., plasma treatment, corona discharge) to enhance surface energy and promote better adhesion. A high-performance adhesive, typically an acrylic or rubber-based pressure-sensitive adhesive (PSA), is then precisely coated onto one side of the strip. This adhesive layer is often protected by a release liner for easy application.

- Curing & Cooling: For certain adhesive types, a curing process (e.g., UV curing, heat curing) ensures optimal adhesive strength and durability. The strip is then cooled to stabilize its shape and material properties.

- Slitting & Packaging: Large rolls of the adhesive strip are precisely cut into specific widths and lengths according to client specifications. Final inspection is performed before packaging.

Throughout this process, stringent quality control measures are implemented. Adherence to standards like ISO 9001 for quality management and ASTM (American Society for Testing and Materials) or ANSI (American National Standards Institute) standards for material properties and testing (e.g., peel strength, shear strength, compression set, aging resistance) is critical. This ensures the product's lifespan and performance in demanding environments, which is a hallmark of a reliable window seal strip adhesive exporter.

Key Technical Advantages and Performance Metrics

The technical prowess of leading window seal strip adhesive manufacturers is reflected in the superior performance metrics of their products. These include exceptional bond strength, measured in pounds per inch (pli) or Newtons per centimeter (N/cm), ensuring secure and lasting adhesion to various substrates like glass, metal, and plastic. Temperature resistance is another crucial parameter, with high-performance strips capable of operating effectively from -40°C to +120°C, crucial for automotive and outdoor construction applications.

Furthermore, excellent UV and ozone resistance prevent degradation over time due to environmental exposure, maintaining sealing integrity. Compression set resistance ensures the strip retains its original shape and sealing capability after prolonged compression, which is vital for long-term sealing. These attributes contribute significantly to benefits like energy savings through improved insulation, enhanced corrosion resistance by preventing moisture ingress, and superior noise dampening, which are critical for specialized sectors such as petrochemical, metallurgy, and water supply/drainage systems where environmental protection and operational efficiency are paramount.

Comparative Analysis of Window Seal Strip Adhesive Suppliers

Selecting the right window seal strip adhesive supplier requires careful consideration of various factors beyond just price. A comprehensive comparison involves evaluating their product range, R&D capabilities, adherence to international standards, customization options, and after-sales support. Below is a representative comparison table showcasing key attributes often found among leading window seal strip adhesive companies. This data helps B2B buyers make informed decisions based on their specific project requirements.

Comparative Overview of Leading Suppliers

This comparison highlights that while all these window seal strip adhesive exporters offer essential products, their core strengths and specialization vary. Companies seeking highly customized, high-performance solutions for automotive or aerospace applications might lean towards Supplier A, while those needing general industrial seals might find Supplier B more suitable.

Custom Solutions and Engineering Capabilities

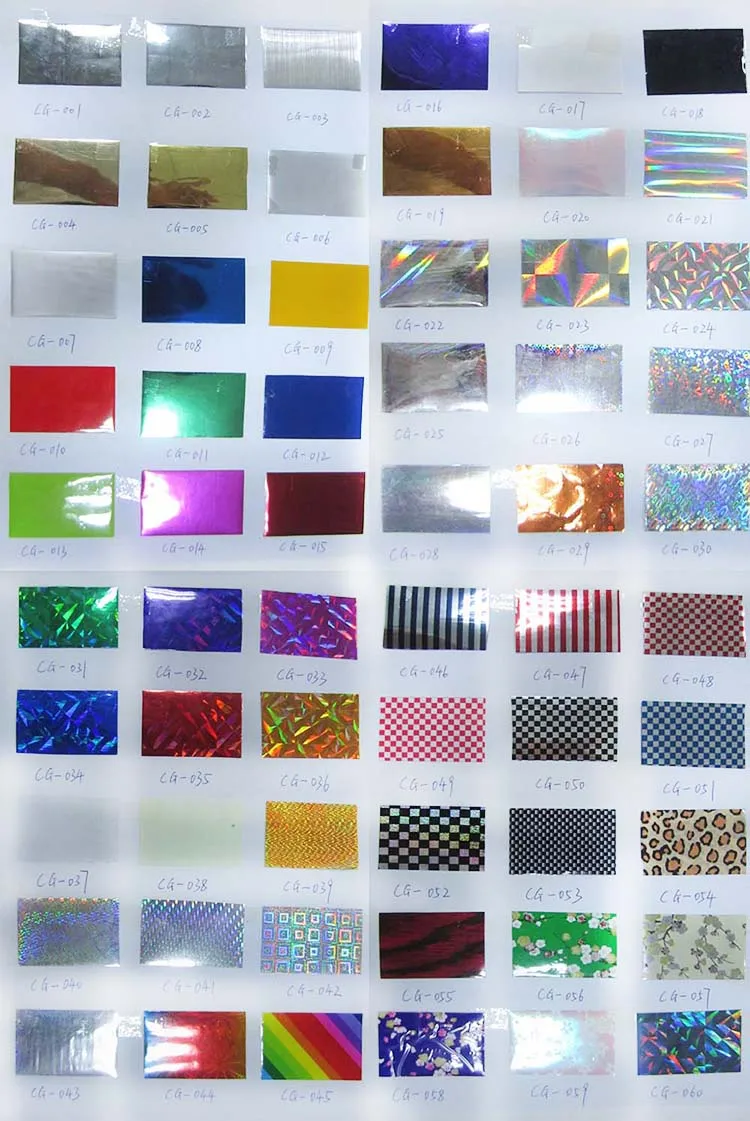

Beyond off-the-shelf offerings, the ability to provide bespoke solutions is a significant differentiator among top window seal strip adhesive companies. Customization can involve tailored profiles to fit unique geometries, specific material formulations for extreme environments (e.g., oil resistance, flame retardancy), or specialized adhesive types for challenging substrates or long-term bonding requirements. This includes variations in adhesive thickness, liner type, and even adhesive patterns.

A skilled window seal strip adhesive factory often collaborates closely with clients from the design phase through prototyping and final production. This involves utilizing advanced CAD/CAM software for profile design, conducting FEA (Finite Element Analysis) to predict performance under stress, and rapid prototyping to accelerate development cycles. Such engineering depth ensures that the final product not only fits perfectly but also delivers optimal performance and durability for its intended application, leading to increased customer satisfaction and project success.

Real-World Application Cases and Success Stories

The practical utility of high-quality adhesive seal strips is best illustrated through their diverse application in various industries. For instance, in the automotive sector, custom-engineered EPDM strips with pressure-sensitive adhesives are widely used for sealing car windows, doors, and trunks. These strips effectively reduce cabin noise by 3-5 dB and prevent water and dust ingress, significantly enhancing passenger comfort and vehicle longevity. Their robust design, capable of withstanding extreme temperatures and continuous vibration, exemplifies the demanding specifications met by reliable window seal strip adhesive products.

Another notable application is in the construction industry, particularly for sealing building facades and window frames. Here, PVC or TPE-based adhesive strips provide superior thermal insulation, reducing energy consumption for heating and cooling by up to 15%. A leading window seal strip adhesive company recently collaborated on a major commercial building project, supplying custom-profiled seals that passed rigorous air permeability tests (e.g., ASTM E283), contributing to the building's LEED certification for energy efficiency. These case studies underscore the tangible benefits and return on investment offered by premium adhesive sealing solutions.

Trustworthiness and Support from Leading Manufacturers

Building trust is paramount for any B2B transaction, and the leading window seal strip adhesive exporters achieve this through transparent processes, robust quality assurance, and excellent customer support. When seeking window seal strip adhesive quotes, it's essential to also inquire about their after-sales services, which often include technical assistance, installation guidance, and performance troubleshooting.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of an adhesive window seal strip?

A: With proper installation and under normal operating conditions, high-quality adhesive seal strips from reputable window seal strip adhesive factories can last 10-20 years, depending on the material and application. - Q: Can these strips be used in extreme temperatures?

A: Yes, many modern seal strips are engineered for extreme temperature resistance, typically ranging from -40°C to +120°C. Always verify the specific product's temperature rating with the window seal strip adhesive manufacturer. - Q: How do I ensure proper adhesion and longevity?

A: Surface preparation is key. Ensure the bonding surface is clean, dry, and free of oils or contaminants. Apply firm, even pressure during installation, and allow adequate time for the adhesive to fully cure, if applicable.

Delivery & Warranty

Standard delivery cycles for bulk orders from established window seal strip adhesive suppliers typically range from 3 to 6 weeks, depending on customization requirements and order volume. Expedited options may be available for urgent needs. Reputable companies provide comprehensive warranties, often covering material defects and manufacturing flaws for a specified period (e.g., 1-5 years), reinforcing their commitment to product quality and reliability.

Conclusion: Partnering for Performance

The landscape of window seal strip adhesive companies is dynamic and innovative, offering a wide array of solutions tailored to demanding industrial and commercial applications. From advanced material compounding to precision extrusion and adhesive coating, the manufacturing process underscores a commitment to engineering excellence. By prioritizing providers that demonstrate robust technical expertise, a history of reliable service, and a proactive approach to R&D, businesses can ensure they procure products that not only meet current performance needs but also anticipate future challenges.

Choosing the right window seal strip adhesive company is a strategic decision that impacts the long-term durability, efficiency, and cost-effectiveness of any project. Emphasizing partnerships with manufacturers and suppliers who adhere to strict quality standards and offer comprehensive support will ultimately lead to superior outcomes and sustained operational advantages.

References

- Adhesion Science and Engineering: The Fundamentals. Edited by M. Chaudhury and A. J. Crosby. Oxford University Press, 2002.

- Handbook of Adhesives and Sealants. By S. Ebnesajjad. William Andrew, 2018.

- Polymer Science and Technology. By R. J. Elias. John Wiley & Sons, 2001.

- ASTM International Standards on Adhesives. American Society for Testing and Materials.

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025