Top window seal strip adhesive companies—OEM, fast quotes?

Sep . 30, 2025 11:35 Back to list

Top window seal strip adhesive companies—OEM, fast quotes?

If you’re shortlisting window seal strip adhesive companies, here’s the straight take from the factory floor and the field. The EPDM sponge profiles coming out of Hebei’s Qinghe cluster, especially the Pulongte line, have been getting attention—for good reasons, not just price.

Industry pulse and why adhesives matter

Demand is shifting toward low-VOC, UV-stable seals with reliable PSA backing. Automotive EVs, high-rise retrofits, and cold-chain doors are driving specs up while tolerances get tighter. Honestly, buyers are tired of curl-up and adhesive ooze. Acrylic PSA with primed EPDM skin is winning—hot-melt still has a place for budget builds, but warranty teams prefer acrylic.

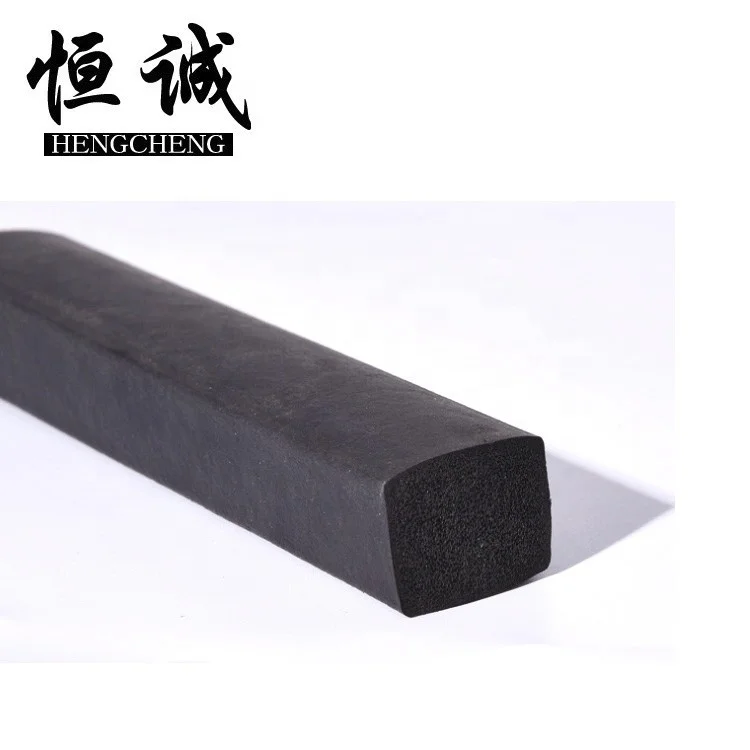

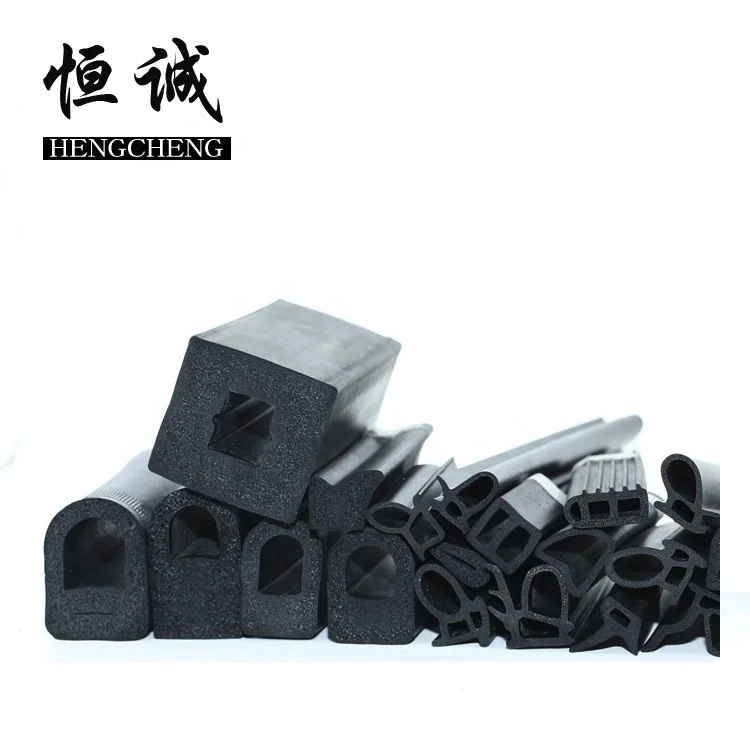

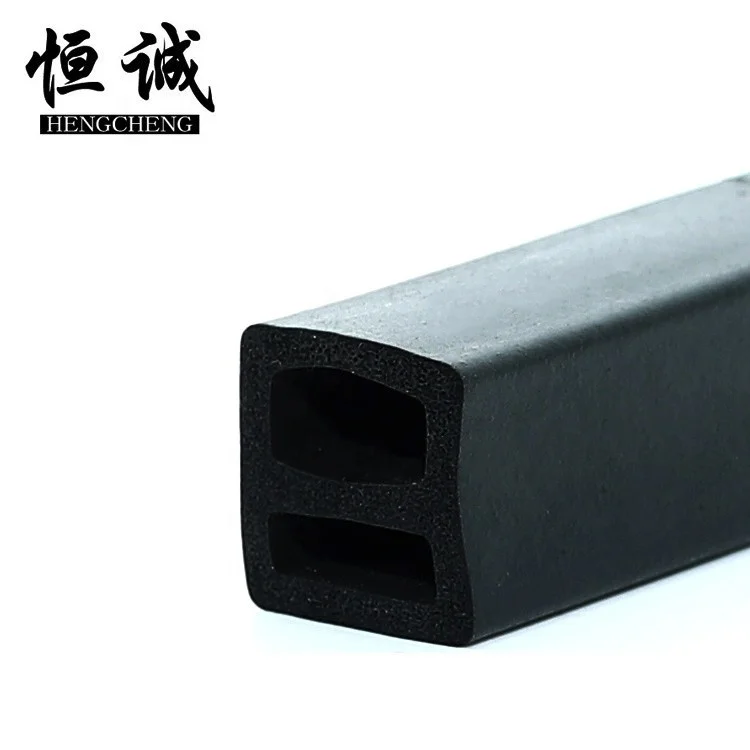

Product spotlight: EPDM sponge extruded seal strip

Product: China rubber seal strip foam rubber seal EPDM sponge extrude rubber foam seal strip. Origin: Xiangjiang Street South, Jinggangshan Road West, Qinghe County, Xingtai City, Hebei Province. To be honest, the extrusion consistency is better than I expected—cell structure is uniform, and the adhesive lamination line is clean.

Core specifications (typical)

| Parameter | Spec (≈, real-world use may vary) | Method |

|---|---|---|

| Material | EPDM closed-cell sponge | ASTM D1056 |

| Density | 0.12–0.25 g/cm³ | ASTM D1056 |

| Hardness | Shore 00: 35–60 | ASTM D2240 |

| Compression Set (22h @70°C) | ≤15% | ASTM D395 |

| Temp Range | -40°C to +120°C (peaks 150°C) | — |

| Adhesive | Acrylic PSA / Hot-melt / Butyl; silicone PSA on request | ASTM D3330 (peel) |

| Flammability | UL 94 HB (typ.) | UL 94 |

| Color | Black (others custom) | — |

How it’s made (quick flow)

Compounding EPDM with blowing agents → sponge extrusion → microwave vulcanization → surface skinning → PSA lamination with primer → slitting/die-cut → coiling → QC (peel, shear, compression set, ozone/UV). Service life? Around 8–12 years outdoors; longer in shaded frames. Tested against ASTM D1149 (ozone) and E283 for air leakage in window assemblies.

Applications and feedback

- Aluminum and uPVC windows/doors; curtain walls; cleanrooms; reefer doors; EV door/body seals; rail stock.

- Installers say the acrylic PSA “bites” well on powder-coated frames after IPA wipe—less lift at corners.

- Certs typically available: ISO 9001, RoHS/REACH; automotive lines may run IATF 16949 audits.

Vendor snapshot (realistic comparison)

| Vendor | Lead Time | MOQ | Adhesive Options | Certs | Indicative Cost |

|---|---|---|---|---|---|

| Pulongte (Hebei) | 10–18 days | ≈3,000 m | Acrylic, hot-melt, butyl | ISO 9001, RoHS | $0.08–0.18/m |

| Ningbo OEM | 15–25 days | ≈5,000 m | Acrylic, hot-melt | ISO 9001 | $0.09–0.22/m |

| EU Supplier | 2–4 weeks | ≈1,000 m | Acrylic, silicone PSA | ISO 9001, REACH | $0.18–0.35/m |

Customization and quick case notes

Profiles: D/P/E/T/H shapes, co-extruded skins, flocked sliding faces. Custom peel strength targeting >12 N/25 mm (ASTM D3330) is common. A retrofit in a coastal high-rise cut air leakage by ~35% (ASTM E283 lab), while an EV door seal program hit 500h ozone without cracks. For facilities teams comparing window seal strip adhesive companies, focus on primer chemistry and post-lamination dwell time. And yes, check storage: 22°C and sealed bags—simple but it matters.

Bottom line? Among window seal strip adhesive companies, Pulongte’s EPDM sponge extrusion with acrylic PSA is a safe, scalable default—unless you need silicone PSA for high-temp glass façades, which is niche but available.

Authoritative citations

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025