Acrylic Heat Bender Tool A: Precision & Durability | Hebei Pulongte

Sep . 29, 2025 02:20 Back to list

Acrylic Heat Bender Tool A: Precision & Durability | Hebei Pulongte

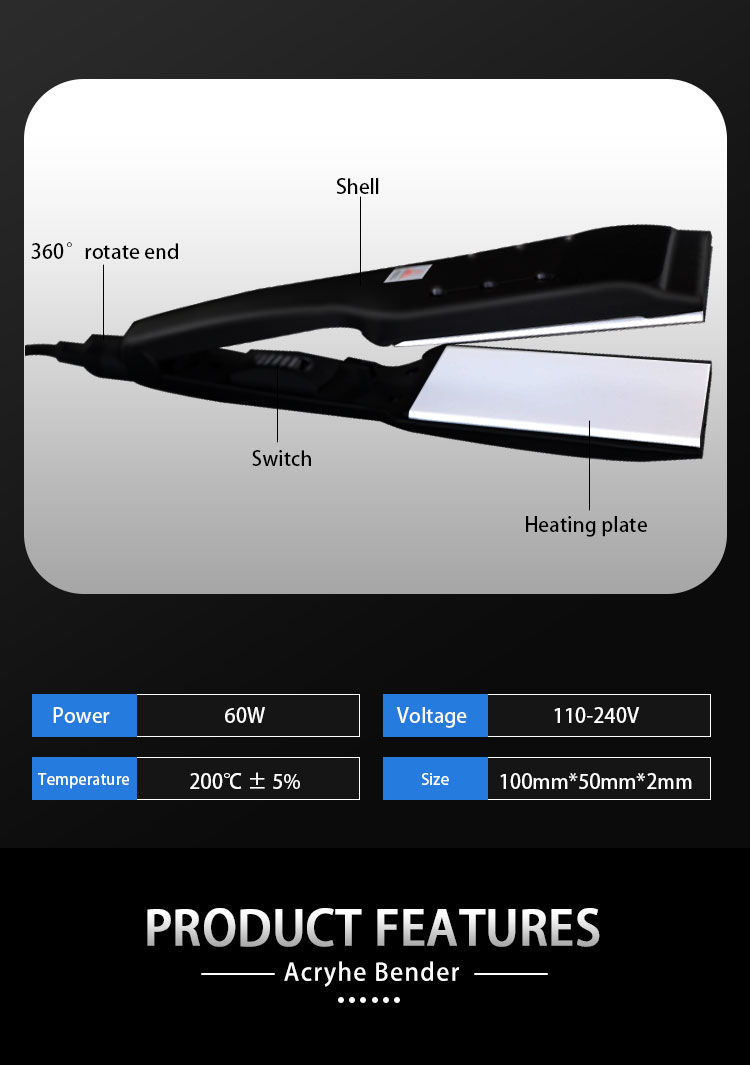

The Acrylic Heat Bender Tool-Type A has revolutionized the acrylic manufacturing industry with its advanced design and reliable performance. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., this tool combines precision engineering with user-friendly functionality to meet the demands of modern production processes. Whether you're a professional fabricator or a DIY enthusiast, this tool offers unmatched versatility and efficiency. Below, we explore its core features, technical specifications, and real-world applications.

Key Features of the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A is engineered to deliver exceptional results in acrylic shaping. Its standout features include:

- Advanced Heating System: The tool utilizes a high-efficiency heating element that ensures even temperature distribution, preventing material warping during the bending process.

- Durable Construction: Built with reinforced materials, the tool withstands prolonged use while maintaining structural integrity.

- User-Friendly Design: Intuitive controls and ergonomic handles make it accessible for both beginners and experts.

- Adjustable Temperature Settings: Users can customize heat levels to suit different acrylic thicknesses and project requirements.

- Quick Setup: The tool is designed for rapid assembly, reducing downtime and increasing productivity.

Advantages Over Traditional Methods

Compared to conventional acrylic bending techniques, the Acrylic Heat Bender Tool-Type A offers several advantages:

- Enhanced Precision: The tool’s precise temperature control ensures accurate bends, minimizing material waste.

- Time Efficiency: Its rapid heating and cooling cycles significantly reduce production time.

- Cost-Effectiveness: By reducing errors and rework, the tool lowers overall operational costs.

- Improved Safety: Built-in safety mechanisms prevent overheating and accidental burns.

- Wide Application Range: Suitable for both small-scale projects and industrial production.

Technical Specifications

| Specification | Details |

|---|---|

| Heating Element | High-efficiency ceramic heating coil |

| Temperature Range | 100°C – 200°C (adjustable) |

| Power Consumption | 1500W |

| Material | Stainless steel and heat-resistant plastic |

| Dimensions | 300mm x 200mm x 150mm |

| Weight | 2.5kg |

| Control System | Digital temperature display and knob |

Applications in Acrylic Manufacturing

The Acrylic Heat Bender Tool-Type A is widely used in various industries due to its adaptability. Key applications include:

- Lighting Fixtures: Creating custom lampshades and diffusers with precise curvature.

- Architectural Elements: Fabricating acrylic panels for partitions, ceilings, and decorative features.

- Signage and Displays: Producing curved acrylic signs and exhibition stands.

- Industrial Components: Manufacturing parts for machinery and equipment requiring heat-formed acrylics.

- Consumer Goods: Crafting items like acrylic trims, decorative caps, and custom container111s.

About Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Hebei Pulongte Rubber and Plastic Technology Co., Ltd. is a leading manufacturer specializing in acrylic and plastic products, with a strong reputation for innovation and quality. The company has been serving the global market for over a decade, providing solutions that meet the evolving needs of industries ranging from construction to consumer goods. Their commitment to precision engineering and customer satisfaction has positioned them as a trusted partner for businesses worldwide.

For more information about the company and its product line, visit their official website.

Why Choose the Acrylic Heat Bender Tool-Type A?

Investing in the Acrylic Heat Bender Tool-Type A offers long-term benefits for manufacturers and fabricators. Here’s why:

- Reliability: The tool’s robust design ensures consistent performance even under demanding conditions.

- Scalability: Suitable for both small workshops and large-scale production facilities.

- Support and Warranty: Hebei Pulongte provides comprehensive after-sales support and a warranty to guarantee customer satisfaction.

- Environmental Compliance: The tool is designed with energy-efficient components to reduce environmental impact.

Authoritative Citations

According to the National Institute of Standards and Technology (NIST), "Standards play a critical role in ensuring the quality and reliability of manufacturing processes. By adhering to established benchmarks, companies can enhance product consistency and safety." This aligns with Hebei Pulongte’s commitment to excellence in acrylic manufacturing.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025