Top Window Seal Strip Adhesive Companies | Strong Adhesion, Energy Saving

Sep . 11, 2025 08:20 Back to list

Top Window Seal Strip Adhesive Companies | Strong Adhesion, Energy Saving

The Pivotal Role of window seal strip adhesive companies in Modern Industrial Applications

In the realm of B2B manufacturing and construction, the integrity of sealing solutions is paramount. From preventing energy loss in buildings to ensuring the operational longevity of industrial machinery, high-performance sealing materials are indispensable. At the core of this critical sector are window seal strip adhesive companies, specializing in the design, manufacturing, and supply of advanced sealing products. These entities are not merely suppliers; they are crucial partners in delivering solutions that enhance energy efficiency, provide environmental protection, and ensure the structural integrity of a vast array of applications across diverse industries. The market for sophisticated window and door seal strips, particularly those utilizing robust materials like EPDM rubber with integrated adhesive systems, is experiencing significant growth, driven by stringent regulatory standards and the continuous pursuit of superior performance.

The demand for durable, weather-resistant, and easily applicable sealing solutions has positioned leading window seal strip adhesive manufacturers at the forefront of innovation. Their expertise extends beyond mere product creation to encompass material science, precision engineering, and comprehensive quality assurance. This article delves into the intricate world of these specialized companies, exploring their manufacturing processes, technical advantages, application scenarios, and the critical factors that B2B clients should consider when sourcing these essential components.

Industry Trends Shaping the Future of Seal Strip Manufacturing

The landscape for window seal strip adhesive companies is continually evolving, influenced by several key trends:

- Sustainability and Eco-Friendly Materials: A growing emphasis on environmental responsibility drives the adoption of recyclable materials, reduction of volatile organic compounds (VOCs) in adhesives, and energy-efficient manufacturing processes. Many window seal strip adhesive factories are investing in greener production lines.

- Enhanced Performance Requirements: Industries such as automotive and construction demand seal strips with superior resistance to extreme temperatures, UV radiation, ozone, and chemical exposure, leading to innovations in polymer compounds like advanced EPDM formulations.

- Smart Manufacturing and Automation: The integration of Industry 4.0 technologies, including IoT, AI, and advanced robotics, is optimizing production efficiency, quality control, and customization capabilities for window seal strip adhesive suppliers.

- Customization and Bespoke Solutions: The market increasingly requires tailor-made profiles, specific material hardness, and custom adhesive properties to meet unique application challenges, pushing window seal strip adhesive product lines towards greater versatility.

- Global Supply Chain Resilience: Geopolitical shifts and recent global events have highlighted the need for diversified and resilient supply chains, influencing how window seal strip adhesive exporters manage their logistics and sourcing strategies.

Manufacturing Process Flow of EPDM Rubber Extrusion Weatherstrip

The production of high-quality EPDM rubber extrusion weatherstrip, a core product for many window seal strip adhesive companies, involves a series of meticulously controlled stages to ensure superior performance and longevity. The emphasis is on precision, material integrity, and adherence to international quality standards.

-

Material Preparation and Compounding:

High-grade Ethylene Propylene Diene Monomer (EPDM) rubber is selected for its excellent weather resistance, ozone resistance, and thermal stability. The raw EPDM polymer is mixed with various additives including carbon black (for UV resistance and strength), reinforcing fillers, plasticizers, curatives (e.g., sulfur or peroxides for vulcanization), and processing aids in a high-shear mixer (e.g., Banbury mixer). This compounding process is crucial for achieving the desired physical and chemical properties of the final seal strip.

-

Extrusion:

The compounded EPDM material is fed into an extruder. Under heat and pressure, the material is forced through a die, which is precisely engineered to form the desired profile of the weatherstrip (e.g., flat, D-shape, P-shape). This continuous process ensures uniform cross-section and dimensional accuracy. Sophisticated extruders can achieve intricate profiles, essential for specific sealing applications.

-

Vulcanization (Curing):

Immediately after extrusion, the uncured EPDM profile undergoes vulcanization, typically in a continuous curing line such as a microwave or hot-air oven. This process chemically cross-links the polymer chains, transforming the soft, plastic-like rubber into a durable, elastic, and high-performance material. Proper vulcanization is key to achieving optimal compression set, tensile strength, and environmental resistance. This stage is critical for the long service life of the product.

-

Cooling and Cutting:

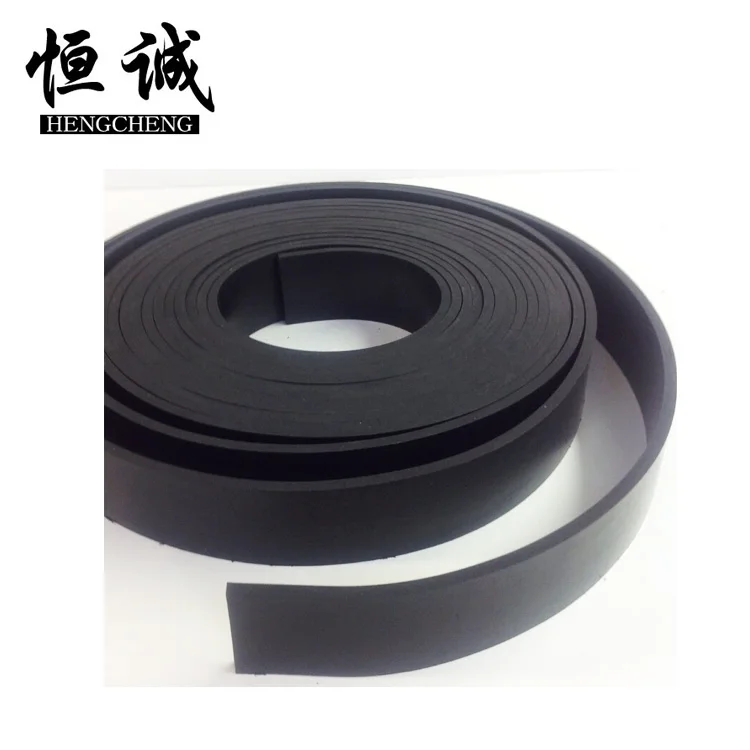

Post-vulcanization, the cured rubber profile is cooled, often through water baths or air cooling, to stabilize its dimensions. It is then cut to specified lengths using automated cutting machinery, ensuring precision for various application requirements.

-

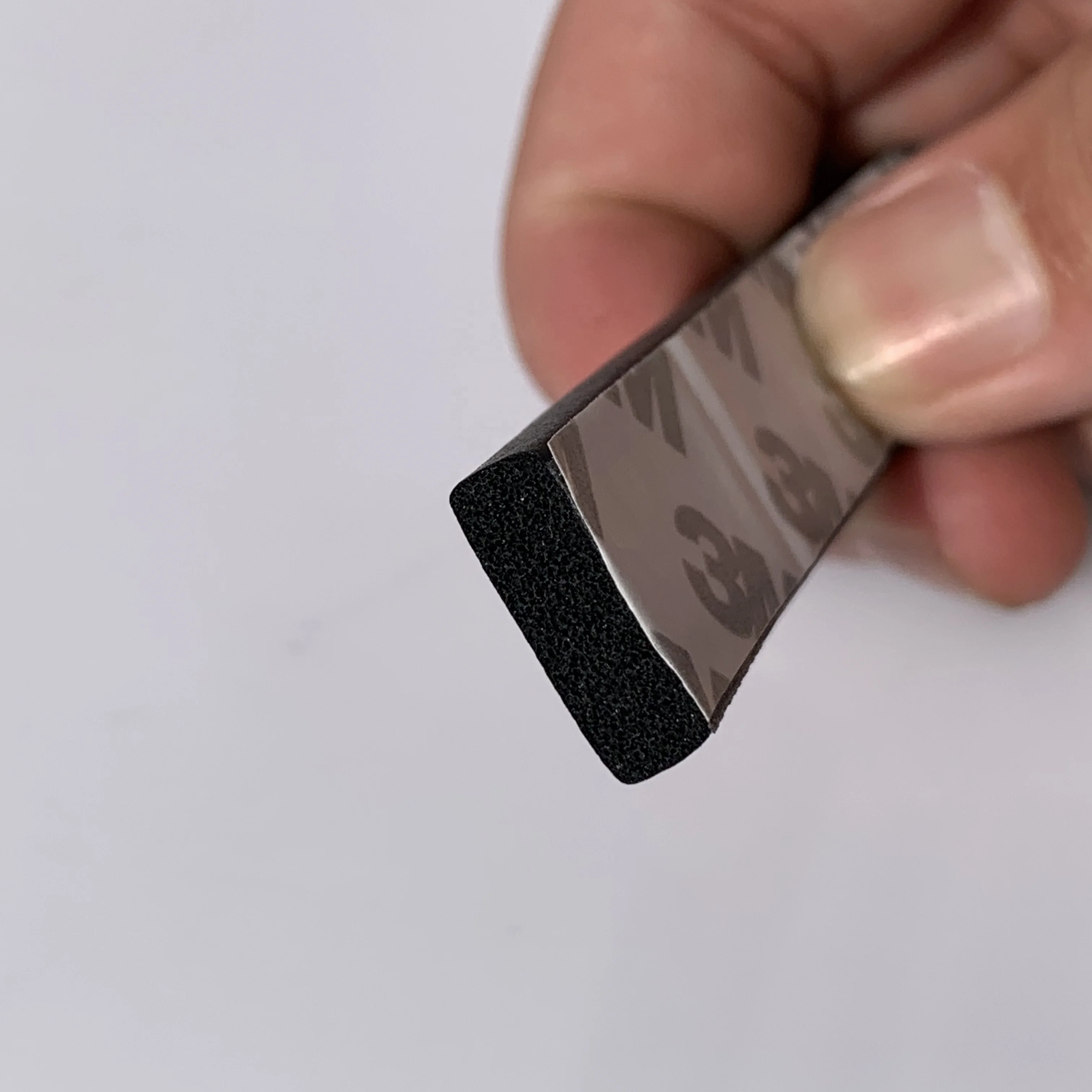

Adhesive Application:

For self-adhesive weatherstrips, a high-tack, durable adhesive layer (often pressure-sensitive acrylic or rubber-based) is applied to one side of the EPDM profile. This adhesive is typically backed by a release liner for easy installation. The choice of adhesive is critical, influencing bond strength, temperature range, and surface compatibility.

-

Quality Control and Testing:

Throughout the process, rigorous quality control measures are implemented. This includes checking dimensional accuracy, hardness (Shore A), tensile strength, elongation at break, compression set, ozone resistance, UV stability, and adhesive peel strength. Products are tested against international standards such as ISO 9001 for quality management, ASTM D2000 for rubber materials, and relevant automotive (e.g., SAE) or construction (e.g., ANSI) standards. This ensures that the window seal strip adhesive products meet or exceed customer specifications and boast a service life often exceeding 10-15 years under typical operating conditions.

-

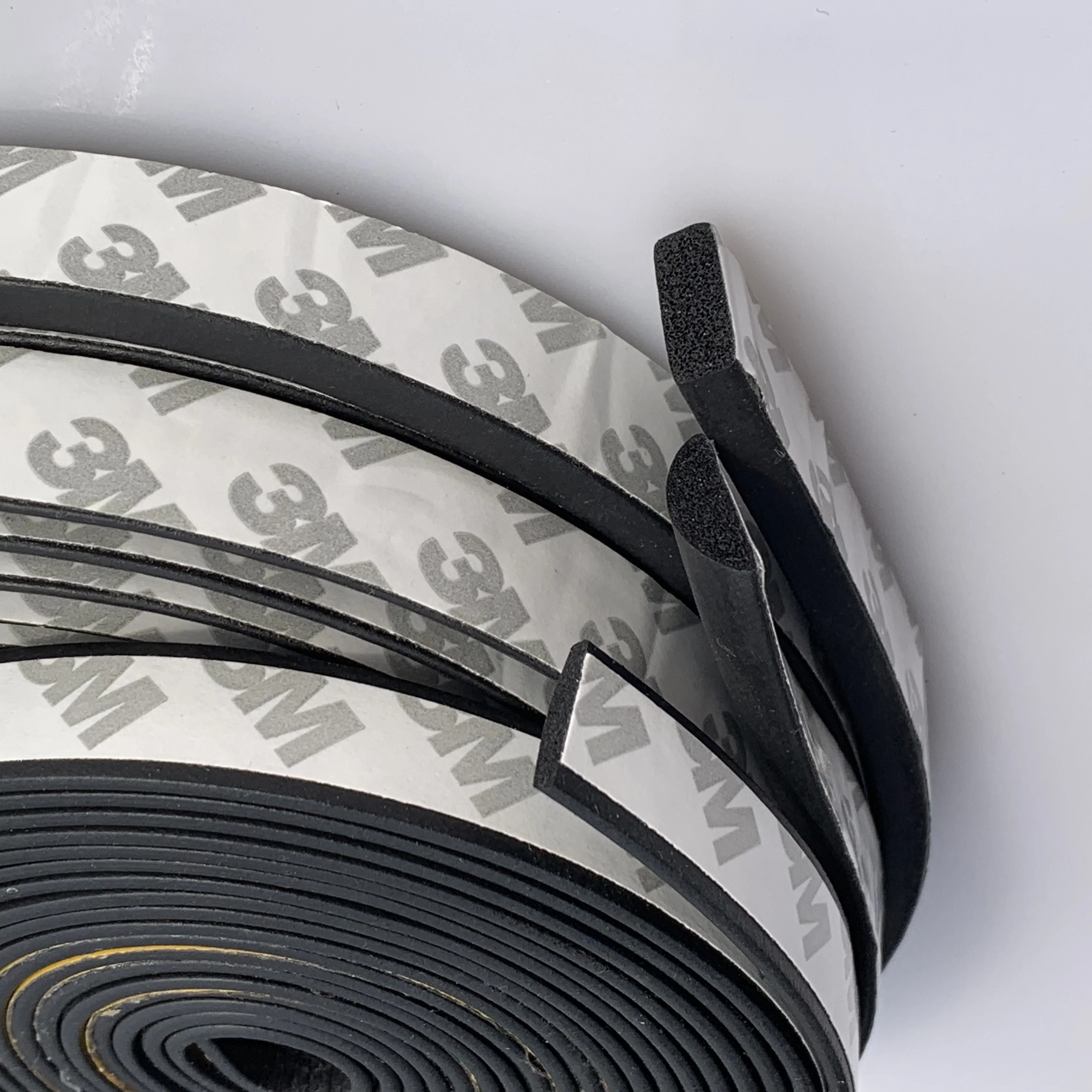

Packaging and Dispatch:

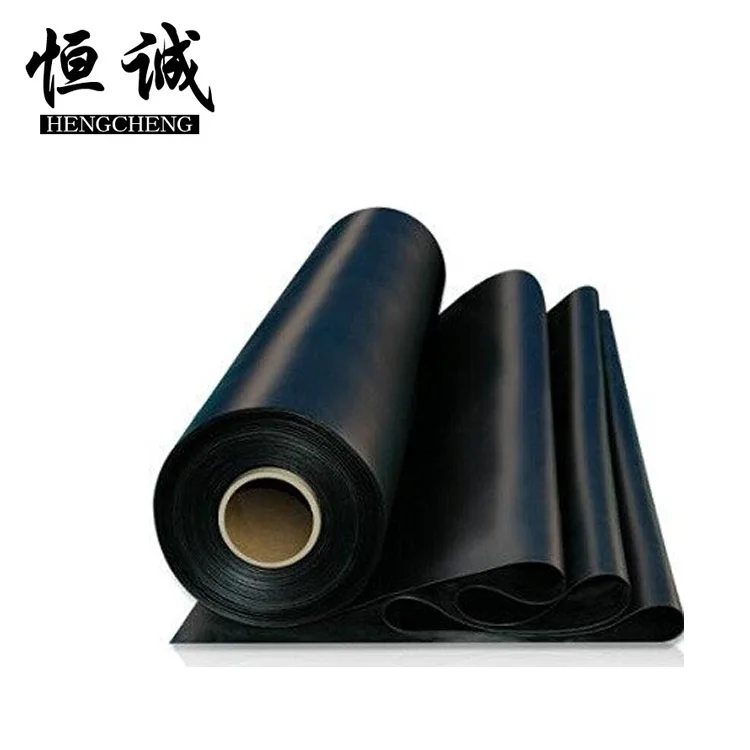

Finished seal strips are carefully packaged, often in rolls or custom lengths, to prevent damage during transit and storage, ready for dispatch by window seal strip adhesive exporters.

This comprehensive process allows window seal strip adhesive companies to produce solutions with advantages like significant energy saving (by preventing air infiltration), superior corrosion resistance (EPDM does not degrade from many chemicals), excellent noise reduction, and robust weather sealing in diverse target industries such as automotive, construction, HVAC, marine, and industrial enclosure manufacturing.

Technical Specifications & Parameters (: Expertise & Authoritativeness)

Understanding the technical specifications of EPDM rubber extrusion weatherstrips is crucial for B2B decision-makers. Key parameters define performance, durability, and suitability for specific applications. Below is a typical specification table for an EPDM Rubber Extrusion Weatherstrip Flat Cabinet Door Rubber Seal Strip, similar to products offered by leading window seal strip adhesive factories.

EPDM Rubber Extrusion Weatherstrip Technical Specifications

| Parameter | Typical Value/Range | Test Standard |

|---|---|---|

| Material | EPDM (Ethylene Propylene Diene Monomer) Rubber | ASTM D1418 |

| Hardness | 60-75 Shore A | ASTM D2240 |

| Tensile Strength | ≥ 7 MPa (1000 psi) | ASTM D412 |

| Elongation at Break | ≥ 300% | ASTM D412 |

| Compression Set (22h @ 70°C) | ≤ 30% | ASTM D395, Method B |

| Temperature Range | -40°C to +120°C (-40°F to +250°F) | ISO 188 / ASTM D573 |

| Ozone Resistance | Excellent (No cracking after 100h @ 50 pphm) | ASTM D1149 |

| UV Resistance | Excellent | ASTM G154 / G155 |

| Water Absorption | Low ( | ASTM D471 |

| Adhesive Type | Acrylic or Rubber-based Pressure Sensitive Adhesive (PSA) | Internal Testing / ASTM D3330 (Peel Adhesion) |

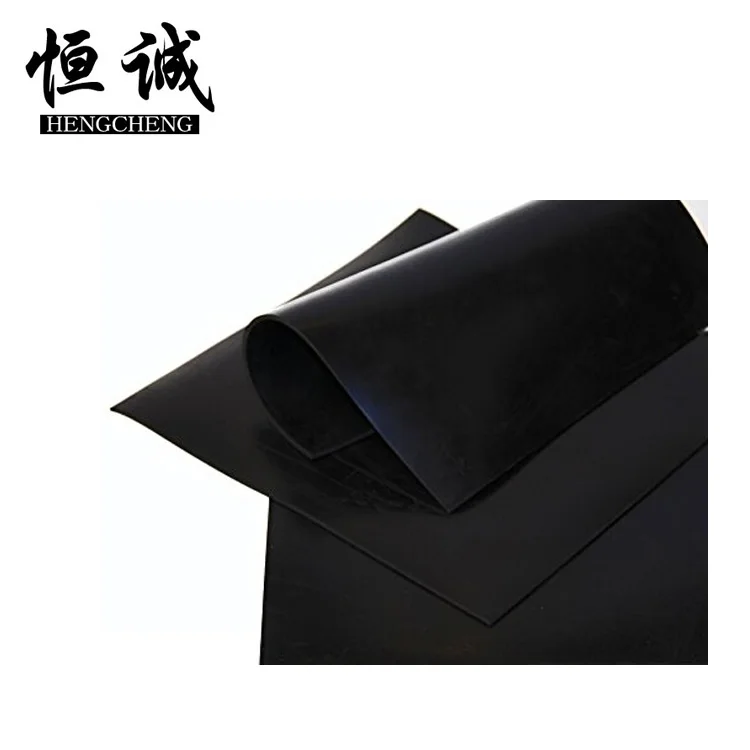

| Standard Colors | Black, Grey (Custom colors available) | Visual Inspection |

These parameters are validated through stringent testing procedures, often conducted in-house by experienced engineers or through accredited third-party laboratories, providing authoritative data on product performance. Reputable window seal strip adhesive companies transparently provide these specifications, often backed by ISO/TS certified manufacturing processes.

Application Scenarios & Case Studies (: Experience)

EPDM window seal strips with adhesive backing are versatile solutions employed across numerous sectors, contributing to enhanced product performance and operational efficiency. Here are typical application scenarios and illustrative case studies:

-

Automotive Industry: Used in car doors, windows, trunks, and sunroofs to prevent water and dust ingress, reduce cabin noise, and minimize vibrations.

Case Study: A leading automotive manufacturer integrated custom-profile EPDM seal strips from a prominent window seal strip adhesive company into their new EV platform. The strips, optimized for specific compression loads and UV exposure, contributed to a 15% reduction in cabin noise levels and passed accelerated weathering tests for over 10 years of service life, leading to enhanced customer satisfaction and reduced warranty claims related to sealing failures.

-

Construction and Building Envelopes: Crucial for sealing windows, doors, curtain walls, and expansion joints in residential, commercial, and industrial buildings. They prevent air and water leakage, improving energy efficiency.

Case Study: A large commercial building project in a coastal region utilized advanced adhesive-backed EPDM seals from a reputable window seal strip adhesive manufacturer for all external window and door frames. The excellent salt spray and moisture resistance of the seals ensured the building maintained its thermal performance and avoided water damage, even after years of exposure to harsh marine environments. Energy audit data showed a 10-12% improvement in HVAC efficiency compared to similar buildings using conventional sealing methods.

- HVAC Systems and Industrial Enclosures: Sealing access panels, ducts, and cabinet doors in HVAC units, electrical enclosures, and industrial machinery to protect sensitive components from dust, moisture, and temperature fluctuations.

- Marine Applications: Used in boat hatches, portholes, and cabins for waterproofing and weatherproofing against harsh marine conditions.

- Appliance and Cabinet Manufacturing: Employed in refrigerators, ovens, washing machines, and various cabinet doors to provide dust and moisture seals, improve thermal insulation, and reduce noise. This is particularly relevant for the EPDM Rubber Extrusion Weatherstrip Flat Cabinet Door Rubber Seal Strip.

Customer feedback consistently highlights the long-term reliability and performance of well-engineered EPDM seal strips. For instance, an industrial client reported a significant reduction in machinery downtime due to dust-related failures after upgrading their cabinet seals with products from a specialized window seal strip adhesive supplier, underscoring the tangible benefits of quality sealing solutions.

Technical Advantages of EPDM Seal Strips

EPDM rubber offers a compelling suite of technical advantages that make it a preferred material for high-performance seal strips, particularly when integrated with a reliable adhesive system. Leading window seal strip adhesive companies leverage these properties to deliver superior products:

- Exceptional Weather Resistance: EPDM is inherently resistant to harsh weather conditions, including rain, snow, and extreme temperatures, making it ideal for outdoor and exposed applications.

- Superior UV and Ozone Resistance: Unlike many other rubbers, EPDM exhibits outstanding resistance to degradation from ultraviolet light and ozone, preventing cracking and hardening over time. This contributes significantly to its extended service life.

- Wide Temperature Range: It maintains its flexibility and sealing properties across a broad temperature spectrum, typically from -40°C to +120°C, ensuring consistent performance in diverse climates.

- Excellent Chemical Resistance: EPDM resists many polar solvents, alkalis, dilute acids, and steam, enhancing its suitability for industrial environments where chemical exposure is a concern.

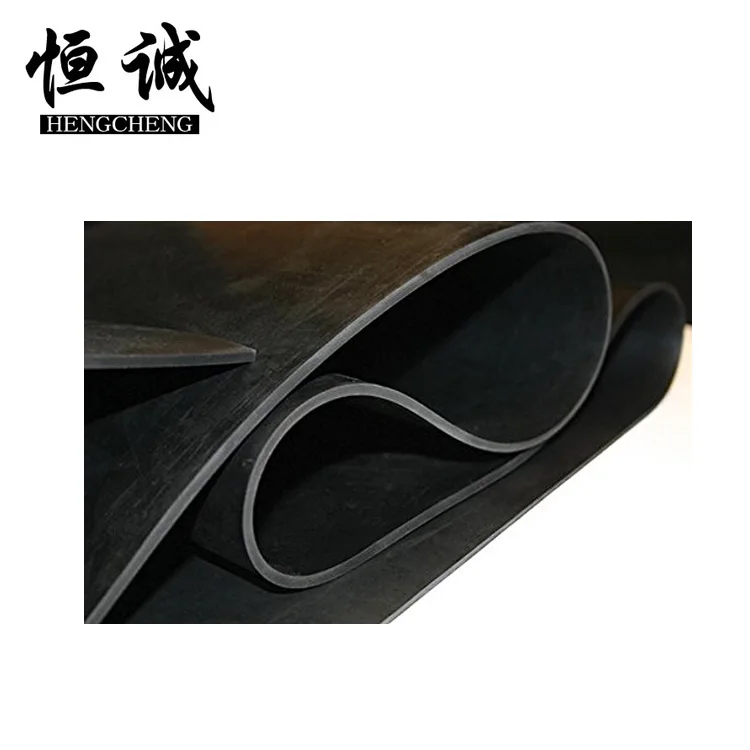

- Low Compression Set: This property means that EPDM retains its elasticity and ability to rebound after being compressed, maintaining a tight seal over long periods without permanent deformation.

- Noise and Vibration Damping: The inherent elasticity of EPDM helps to absorb shock and reduce noise transmission, contributing to quieter and smoother operation in applications like vehicle interiors and machinery enclosures.

- Ease of Installation: With integrated adhesive backing, these seal strips offer a clean, fast, and efficient installation process, reducing labor costs and simplifying assembly for manufacturers.

These combined advantages result in durable, energy-efficient, and cost-effective sealing solutions that provide long-term value for B2B clients, a hallmark of reliable window seal strip adhesive companies.

Vendor Comparison: Choosing the Right Window Seal Strip Adhesive Exporter

Selecting the right window seal strip adhesive company is a strategic decision that impacts product quality, supply chain reliability, and overall project success. B2B purchasers should evaluate potential vendors based on several critical criteria:

- Quality Certifications: Look for ISO 9001 (Quality Management), ISO/TS 16949 (Automotive), or other industry-specific certifications. These indicate adherence to rigorous quality standards in manufacturing.

- R&D Capabilities and Technical Expertise: A strong R&D department signifies a window seal strip adhesive manufacturer's ability to innovate, develop custom solutions, and provide in-depth technical support.

- Customization Options: The ability to provide custom profiles, material compounds, colors, and adhesive types is vital for meeting unique application requirements.

- Production Capacity and Lead Times: Ensure the window seal strip adhesive factory can meet demand, especially for large-volume orders, with reasonable and consistent lead times.

- Pricing and Cost-Effectiveness: While cost is a factor, it should be balanced against quality, performance, and the total cost of ownership (considering longevity and reduced maintenance). Request clear window seal strip adhesive quotes that detail all costs.

- After-Sales Support and Warranty: Evaluate the vendor's commitment to customer service, technical assistance, and product warranties.

Material Comparison: EPDM vs. Other Common Seal Materials

| Property | EPDM Rubber | PVC (Polyvinyl Chloride) | Silicone Rubber |

|---|---|---|---|

| Weather Resistance (UV, Ozone) | Excellent | Good (can harden/crack over time) | Excellent |

| Temperature Range | -40°C to +120°C | -20°C to +70°C | -60°C to +230°C |

| Compression Set | Very Good | Fair to Good | Excellent |

| Chemical Resistance | Good (polar solvents, dilute acids) | Good (oils, fuels) | Excellent (wide range) |

| Flame Resistance | Poor to Fair | Good (self-extinguishing) | Excellent |

| Cost-Effectiveness | Excellent | Very Good (lower initial cost) | Higher |

This comparison highlights EPDM's balanced properties, offering an excellent blend of weather resistance, durability, and cost-effectiveness for most sealing applications. While silicone offers superior high-temperature and flame resistance, EPDM typically provides a more economical solution for general-purpose outdoor and industrial sealing needs.

Customized Solutions from Window Seal Strip Adhesive Companies

One of the hallmarks of a professional window seal strip adhesive company is its capability to offer bespoke solutions tailored to specific project requirements. Standard profiles may not always suffice for unique architectural designs, specialized industrial machinery, or niche automotive applications. Customization extends to:

- Custom Profiles and Geometries: From complex multi-chamber designs to specific edge configurations, window seal strip adhesive factories can develop custom dies to extrude precise shapes that fit seamlessly into challenging spaces, ensuring optimal sealing performance.

- Material Compounding: Adjusting the EPDM compound to achieve specific properties such as higher hardness (e.g., 80 Shore A for heavy-duty applications), improved oil resistance, or enhanced flame retardancy to meet particular industry standards (e.g., UL94).

- Adhesive Selection: Offering a range of adhesive types (e.g., high-tack acrylics for challenging surfaces, rubber-based for lower temperatures, or heat-activated) to ensure maximum bond strength and longevity for various substrates.

- Color Matching: Producing seal strips in custom colors to match aesthetic requirements or for color-coding in complex assemblies.

- Specific Lengths and Packaging: Providing seals cut to precise lengths or packaged in specific quantities to optimize assembly line efficiency for the client.

The customization process typically involves initial consultation, CAD design, prototyping, rigorous testing, and final production, ensuring the bespoke solution meets all performance criteria. This collaborative approach between the client and the window seal strip adhesive company is key to achieving optimal results.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lifespan of EPDM window seal strips?

A: High-quality EPDM seal strips typically have a service life of 10-20 years, depending on the specific application, environmental exposure, and initial material quality. Their excellent resistance to UV, ozone, and temperature extremes contributes to their longevity.

-

Q: Can these seal strips be used outdoors in harsh climates?

A: Absolutely. EPDM is renowned for its superior weather resistance, making it an ideal choice for outdoor applications exposed to extreme temperatures, heavy rainfall, snow, and strong sunlight. Most window seal strip adhesive companies design their EPDM products for such conditions.

-

Q: What types of surfaces can the adhesive backing stick to?

A: The adhesive backing is designed for strong adhesion to a variety of clean, dry, and non-porous surfaces, including painted metal, glass, plastic (PVC, ABS), and wood. For optimal adhesion, surface preparation (cleaning, degreasing) is crucial.

-

Q: Are custom sizes and profiles available?

A: Yes, leading window seal strip adhesive companies offer extensive customization options, including specific dimensions, unique cross-sectional profiles, and various material compounds to meet precise application needs.

Lead Time, Fulfillment, and Warranty Commitments

Reliable window seal strip adhesive companies understand the importance of timely delivery and robust support for B2B clients.

- Lead Time: Standard products typically have lead times ranging from 2-4 weeks, depending on order volume and current production schedules. Custom orders may require 6-10 weeks, encompassing design, prototyping, and tooling. Expedited services are often available upon request.

- Fulfillment and Logistics: Experienced window seal strip adhesive exporters offer flexible shipping options, including sea, air, and express delivery, with capabilities for global distribution. They manage customs documentation and provide real-time tracking to ensure smooth delivery.

- Warranty: Most reputable manufacturers provide a warranty against manufacturing defects, typically ranging from 1 to 5 years, ensuring product integrity and performance under specified conditions. This commitment underscores their confidence in product quality.

- Customer Support: Comprehensive after-sales support includes technical assistance for installation queries, troubleshooting, and guidance on product selection. Dedicated account managers ensure continuous client satisfaction.

Conclusion

The selection of high-quality sealing solutions from reliable window seal strip adhesive companies is a fundamental aspect of modern engineering and manufacturing. As industries continue to demand higher performance, greater efficiency, and enhanced sustainability, the role of specialized manufacturers producing advanced EPDM rubber extrusion weatherstrips becomes even more critical. By understanding the intricate manufacturing processes, technical specifications, diverse application scenarios, and the comprehensive support structures offered by these companies, B2B decision-makers can make informed choices that contribute significantly to the longevity, safety, and operational excellence of their products and projects.

References

- ASTM International. (2023). Standards for Rubber and Rubber Products. Retrieved from astm.org

- ISO (International Organization for Standardization). (2023). ISO 9001 Quality Management. Retrieved from iso.org

- Rubber Manufacturers Association (RMA). (2023). Rubber Handbook: Physical Properties and Applications.

- European Rubber Journal. (2023). Market Trends and Innovations in Rubber Processing. Retrieved from europeanrubberjournal.com

- ScienceDirect. (2023). Research on EPDM properties and industrial applications. Retrieved from sciencedirect.com

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025