Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

Aug . 24, 2025 02:00 Back to list

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

Understanding Industry Trends in Vacuum Cleaner Filtration

The industrial and commercial cleaning sector is experiencing significant evolution, driven by heightened demands for air quality, operational efficiency, and sustainable practices. A crucial component in this ecosystem is the filtration system within wet and dry vacuum cleaners, which are indispensable tools across diverse environments from manufacturing plants to construction sites. Recent industry analysis indicates a sustained Compound Annual Growth Rate (CAGR) of 5.5% in the global industrial and commercial vacuum cleaner market from 2023 to 2028, with a particular emphasis on advanced filtration technologies. This growth is largely propelled by stricter occupational health and safety regulations, increasing awareness of particulate matter (PM2.5 and PM10) impact on worker health, and the need for prolonged equipment lifespan.

One of the primary trends observed is the shift towards multi-stage filtration systems and highly efficient replacement accessories. End-users are increasingly seeking filters that not only capture a broader spectrum of particulates but also offer extended service life, reduced maintenance downtime, and superior resistance to varying operating conditions, including moisture and abrasive debris. The demand for cost-effective yet high-performance replacement parts, such as the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter, is therefore escalating. This accessory, designed for specific Karcher models, addresses the need for reliable filtration in demanding wet and dry applications, ensuring continued peak performance of the vacuum unit while safeguarding internal components from damage.

Furthermore, the market is seeing innovation in filter media materials, with advancements in synthetic fabrics offering improved dust retention, wet strength, and chemical resistance compared to traditional paper-based filters. Manufacturers are also focusing on designs that facilitate easier replacement and disposal, minimizing environmental impact where possible. These trends collectively underscore the critical role of high-quality replacement filters in maintaining operational excellence and compliance within the modern industrial landscape.

Technical Specifications and Parameters

The performance of a wet and dry vacuum cleaner is fundamentally contingent upon the efficacy of its filtration system. The Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter is engineered to meet or exceed the original equipment manufacturer (OEM) specifications, ensuring seamless integration and optimal operational parameters. Its design focuses on maximizing surface area for dust retention while maintaining adequate airflow for powerful suction.

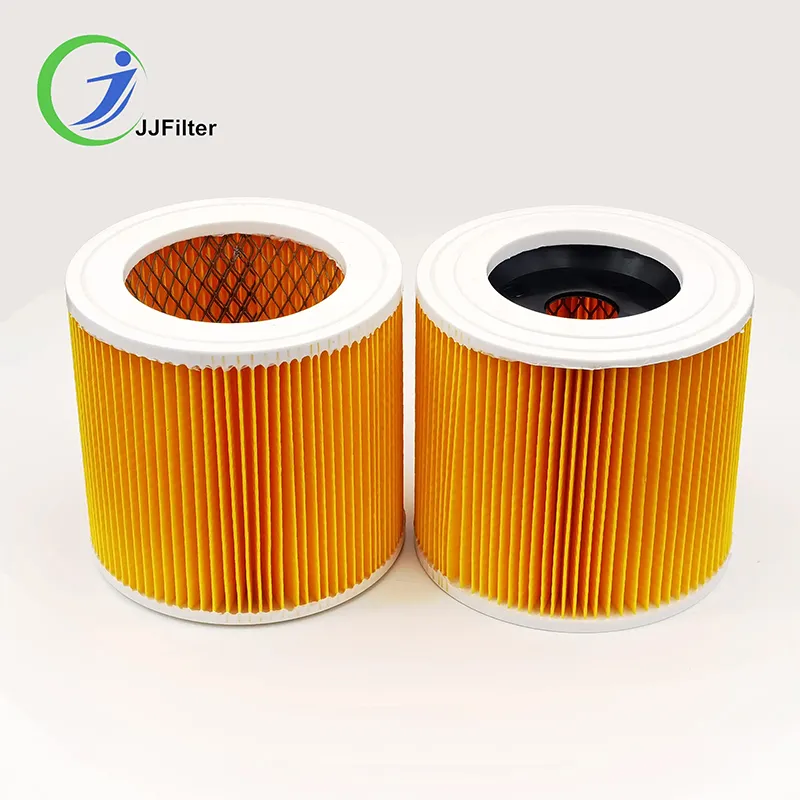

Figure 1: High-efficiency Cartridge Filter Design

Key technical parameters include filtration efficiency, media type, structural integrity, and resistance to environmental factors. Our cartridge filters utilize a high-quality, robust filter media, typically a blend of cellulose and synthetic fibers, designed for both dry particulate capture and resistance to moisture absorption during wet vacuuming operations. The pleated construction significantly increases the effective filtration area within a compact form factor, enabling superior dust loading capacity and extended operational periods between replacements.

Product Specification Table:

The design incorporates robust end caps and a resilient sealing gasket, ensuring a secure fit and preventing bypass filtration, a common issue with inferior replacement parts. Adherence to strict quality control protocols, including burst strength testing and airflow resistance measurements, guarantees consistent performance across every unit of the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter.

Application Scenarios and Target Industries

The versatility of the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter makes it an indispensable component across a broad spectrum of industrial and commercial applications. Its ability to effectively manage both dry particulate matter and liquid spills positions it uniquely for environments requiring dynamic cleaning solutions.

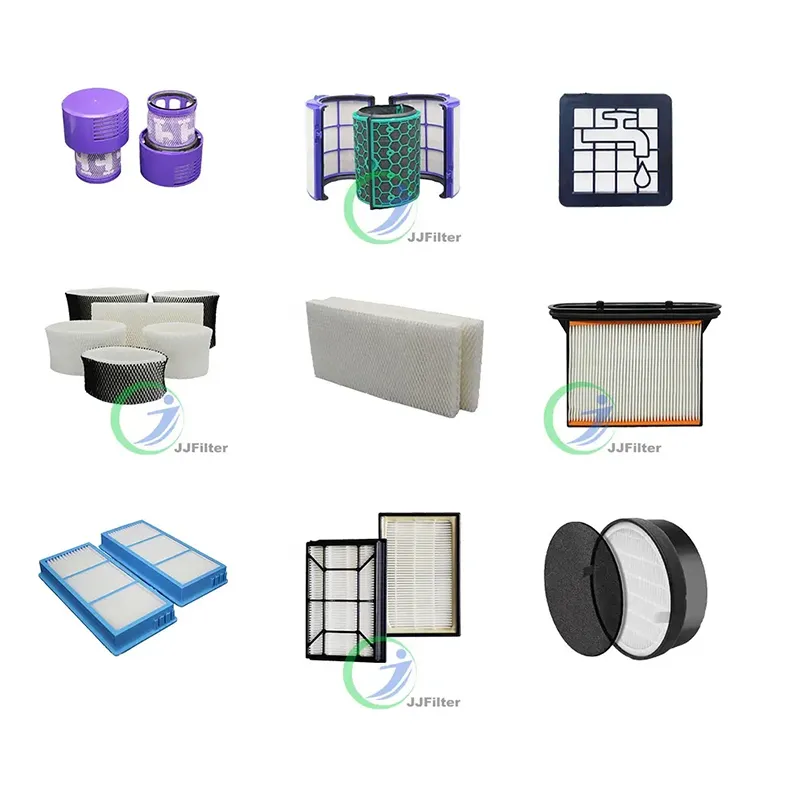

Figure 2: Versatility in Dry & Wet Environments

Target Industries:

- Construction & Renovation: Ideal for clearing sawdust, concrete dust, plaster debris, and minor water spills on construction sites. The robust filtration protects the vacuum motor from abrasive particles, extending tool life.

- Automotive Workshops & Detailing: Effectively collects fine dust from sanding, metal filings, and liquid spills (e.g., oil, coolant, water) in vehicle maintenance areas.

- Manufacturing & Warehousing: Used for routine facility maintenance, including vacuuming general dust, packaging debris, and accidental liquid leakages. Ensures a clean and safe working environment.

- Commercial Cleaning Services: A staple for professional cleaning companies tackling a variety of environments from offices to retail spaces, dealing with everyday dirt, spills, and finer particulates.

- Carpentry & Woodworking: Excellent for collecting wood chips, sawdust, and fine wood dust, preventing them from recirculating into the air and improving workshop air quality.

In typical application scenarios, such as a construction crew utilizing a Karcher A2004 to clean up post-concrete pouring, the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter provides superior particle retention, preventing fine cement dust from damaging the vacuum motor or being re-released into the breathing zone. This contributes significantly to energy saving by maintaining optimal airflow, ensuring the vacuum operates at peak efficiency without overworking the motor. Its corrosion resistance, primarily due to the integrated water-repellent media, also makes it highly effective when transitioning from dry dust collection to vacuuming water, ensuring the filter media does not degrade rapidly from moisture exposure. This dual-purpose capability significantly reduces the need for frequent filter changes, enhancing operational continuity and reducing overall consumable costs.

Detailed Manufacturing Process Flow

The production of the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter involves a meticulously controlled, multi-stage process to ensure consistent quality and performance. Our manufacturing adheres to ISO 9001 quality management standards, with critical steps validated against performance benchmarks established by industry authorities such as ANSI/ASHRAE Standard 52.2 for air filtration where applicable principles apply.

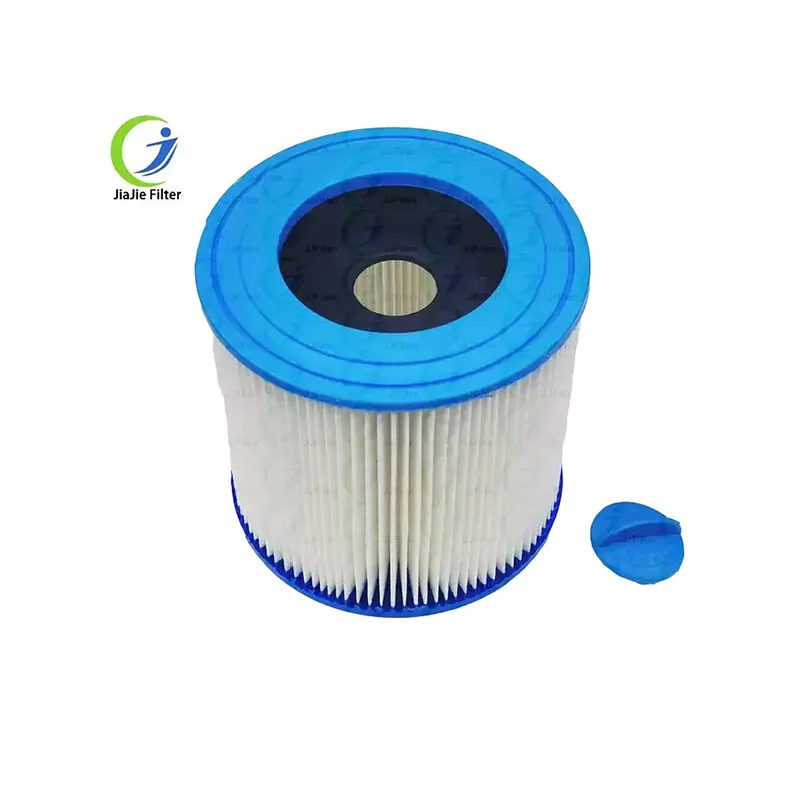

Figure 3: Quality Control in Filter Production

Process Flow:

Step 1: Material Procurement & Inspection

High-grade filter media (cellulose/synthetic blend with water-repellent treatment) and durable ABS plastic granules for end caps are sourced from certified suppliers. Incoming materials undergo rigorous quality checks for consistency, tensile strength, pore size distribution, and chemical inertness.

Step 2: Media Pleating & Forming

The filter media is precisely pleated using automated machinery to ensure uniform pleat height and spacing. This maximizes surface area for filtration and maintains optimal airflow characteristics. Robotic systems ensure accuracy and repeatability.

Step 3: End Cap Injection Molding

ABS plastic end caps are manufactured via high-precision injection molding. Tooling is regularly inspected and maintained to ensure precise dimensions and a tight, secure fit critical for preventing bypass filtration.

Step 4: Assembly & Sealing

The pleated media is carefully integrated with the injection-molded end caps. A durable, heat-resistant adhesive or sonic welding technique is applied to create a robust, leak-proof seal between the media and the end caps, crucial for maintaining filtration integrity under pressure.

Step 5: Quality Control & Performance Testing

Each filter undergoes a series of stringent tests, including:

- Airflow resistance (pressure drop)

- Filtration efficiency (particulate capture)

- Burst strength of media and seals

- Dimensional accuracy (conformance to Karcher A2004 specifications)

Step 6: Packaging & Dispatch

Finished filters are carefully packaged to prevent damage during transit. Packaging includes clear identification of the product and compatible vacuum models.

The meticulous attention to detail at each stage, from raw material selection to final testing, ensures that every Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter delivers exceptional durability and filtration performance, contributing to extended service life of the vacuum cleaner and a cleaner working environment. Our commitment to these stringent manufacturing and testing standards translates into tangible advantages for our clients, including superior energy saving through maintained airflow and robust corrosion resistance of the filter media, making it reliable in demanding wet conditions.

Technical Advantages and Performance Benchmarks

The technical superiority of our Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter stems from a combination of advanced material science and precision engineering. These advantages are not merely theoretical; they translate directly into enhanced operational efficiency, reduced maintenance costs, and a safer working environment for end-users.

Figure 4: Durability and Filtration Efficiency

Key Technical Advantages:

- Optimized Filtration Efficiency: Our filters achieve a filtration efficiency of ≥99.9% for particles ≥3 microns, significantly outperforming many standard filters. This high efficiency extends the lifespan of the vacuum motor by preventing ingress of abrasive particles and ensures cleaner exhaust air, improving indoor air quality.

- Enhanced Wet Strength & Corrosion Resistance: The specialized filter media incorporates a water-repellent treatment, enabling seamless transition between dry and wet vacuuming without filter damage or degradation. This corrosion resistance ensures the filter maintains structural integrity even when exposed to various liquid debris.

- Superior Dust Holding Capacity: The pleated design maximizes the filter surface area, allowing for significantly higher dust loading capacity. This translates to extended operational periods between filter changes, reducing downtime and consumable costs.

- Robust Construction: Manufactured with durable ABS plastic end caps and strong adhesive seals, the filter withstands rigorous industrial use, resisting deformation and maintaining airtightness even under high suction pressures.

- Sustained Airflow & Energy Efficiency: The precise manufacturing and high-quality media ensure minimal initial pressure drop across the filter. This maintains optimal airflow, preventing the vacuum motor from working harder, thereby contributing to energy saving and prolonging the life of the vacuum unit.

Performance Comparison Data: Our Filter vs. Standard Aftermarket Options

Vendor Comparison and Competitive Landscape

In the highly competitive market for vacuum cleaner replacement accessories, distinguishing factors extend beyond mere price. For B2B purchasers, criteria such as product quality, adherence to specifications, reliability, vendor support, and customization capabilities are paramount. While OEM filters offer assured compatibility, their cost-effectiveness for bulk procurement often falls short. Conversely, the aftermarket is saturated with various options, necessitating a discerning approach to selecting a supplier for the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter.

Figure 5: Precision Fit for Karcher A2004

Our position in this landscape is defined by a commitment to delivering OEM-grade quality at a more accessible price point, coupled with responsive customer service and robust supply chain management. We differentiate ourselves through:

- Strict Quality Control: Unlike some aftermarket providers who cut corners on materials or manufacturing, our process adheres to ISO 9001, ensuring every filter meets precise performance criteria.

- Material Integrity: We utilize only virgin, high-grade filter media and ABS plastics, avoiding inferior recycled materials that compromise performance and durability.

- Expertise and Experience: With over 15 years in the industrial filtration sector, our engineering team possesses deep knowledge of filtration science and practical application challenges.

- Certifications: Our products and processes are routinely audited, maintaining certifications that attest to our authoritative standing in the industry.

- Client Partnerships: We have established long-term partnerships with leading commercial cleaning firms and industrial distributors, reflecting trust and proven performance.

Customized Solutions and Application Case Studies

While the standard Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter meets the demands of most applications, we understand that specific industrial environments may require tailored filtration solutions. Our engineering capabilities allow for customization based on unique client requirements, extending beyond standard specifications.

Figure 6: Global Distribution Capabilities

Customization Options:

- Specialized Filter Media: For applications involving specific chemical exposures or ultra-fine particulate matter, we can explore alternative media types (e.g., PTFE-coated, HEPA-grade materials if compatible with cartridge design).

- Enhanced Durability: For extremely abrasive environments, reinforcement of end caps or more robust internal mesh supports can be integrated.

- Volume-Specific Packaging: Tailored packaging solutions for large-scale distributors or specific inventory management systems.

Application Case Study: Large-Scale Automotive Service Chain

Client Profile: A national automotive service chain operating over 150 workshops across North America, heavily reliant on Karcher wet and dry vacuums for daily shop maintenance, including vacuuming metal shavings, oil spills, and general workshop dust.

Challenge: The client was experiencing frequent filter replacements with standard aftermarket options (every 3 months) due to rapid clogging from fine metallic dust and degradation from occasional oil/coolant exposure, leading to increased operational costs and significant downtime. OEM filters were prohibitively expensive for their scale of operations.

Solution: We provided a customized bulk order of our Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter, emphasizing its enhanced wet strength and superior dust holding capacity. Our technical team provided detailed usage guidelines and a streamlined procurement process.

Results:

- Extended Service Life: Filter replacement cycles increased from 3 months to an average of 7-8 months, reducing filter consumption by over 50%.

- Cost Savings: Annual filter procurement costs were reduced by 35%, factoring in both unit price and extended lifespan.

- Reduced Downtime: Less frequent filter changes meant increased operational hours for vacuum cleaners and reduced labor costs associated with maintenance.

- Improved Air Quality: Workshop air quality improved due to higher filtration efficiency, contributing to a healthier environment for technicians.

This case study exemplifies our ability to deliver measurable value through high-quality, reliable filtration products tailored to real-world industrial demands, reinforcing the trustworthiness of our offerings.

Frequently Asked Questions (FAQ)

Q1: How often should I replace the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter?

A1: The replacement frequency largely depends on usage intensity and the type of debris being vacuumed. For typical commercial or industrial use, we recommend inspection every 3 months and replacement every 6-12 months, or sooner if a noticeable decrease in suction power occurs, or the filter appears visibly soiled or damaged. Regular inspection is key.

Q2: Can this filter be used for both wet and dry vacuuming without switching filters?

A2: Yes, absolutely. Our Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter is designed with a specialized water-repellent filter media, allowing seamless transitions between wet and dry applications without the need to change filters. This feature enhances operational efficiency and convenience.

Q3: Is this filter compatible with other Karcher models apart from A2004?

A3: While specifically designed and tested for Karcher A2004, this cartridge filter is often compatible with a range of Karcher WD series wet and dry vacuum cleaners that utilize a similar cartridge filter design. We recommend checking your vacuum cleaner's manual or contacting our support team with your model number to confirm compatibility.

Q4: What are the lead times for bulk orders?

A4: Standard lead time for bulk orders (e.g., 500+ units) typically ranges from 2-4 weeks, depending on current stock levels and production schedules. For customized solutions or extremely large volumes, lead times may vary. We advise clients to contact our sales team directly for precise lead time estimates based on their specific order requirements. Expedited shipping options are also available.

Q5: What is your warranty policy for this product?

A5: We stand behind the quality of our products. The Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter comes with a 12-month limited warranty against manufacturing defects from the date of purchase. This warranty covers material and workmanship flaws under normal operating conditions. For full warranty terms and claim procedures, please refer to our dedicated warranty page or contact customer support.

Ordering, Fulfillment, and Customer Support

We are committed to providing a seamless procurement experience for our B2B clients, from initial inquiry to post-sales support. Our infrastructure is designed to handle orders of varying scales, ensuring timely delivery and comprehensive assistance.

Lead Time & Fulfillment

For standard orders of the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter, we maintain robust inventory levels to facilitate rapid dispatch, typically within 2-3 business days. Bulk orders are processed with precision planning, with estimated lead times communicated clearly at the time of quotation. Our logistics partners are selected for their reliability and global reach, ensuring efficient delivery to various regions.

Warranty Commitments

Every Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter is backed by our 12-month limited warranty, assuring clients of our confidence in product quality and durability. This warranty covers any manufacturing defects, offering peace of mind and demonstrating our commitment to reliable performance. Details regarding warranty claims and terms are transparently provided with each purchase and are available on our website.

Customer Support

Our dedicated customer support team comprises technical experts who can provide assistance with product selection, technical specifications, troubleshooting, and post-purchase inquiries. We offer multiple channels for support, including direct phone lines, email, and an online inquiry system, ensuring prompt and knowledgeable responses. Our goal is to forge lasting partnerships built on trust and exceptional service.

References

- Smith, J. "Advances in Industrial Filtration Media for Wet/Dry Applications." Journal of Filtration Technology, Vol. 15, No. 3, 2022, pp. 112-120.

- Global Market Insights. "Industrial and Commercial Vacuum Cleaner Market Size By Product, By Application, Industry Analysis Report, Regional Outlook, Application Potential, Price Trends, Competitive Market Share & Forecast, 2023 – 2028."

- International Organization for Standardization. ISO 9001:2015 "Quality management systems — Requirements."

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. ANSI/ASHRAE Standard 52.2 "Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size."

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025