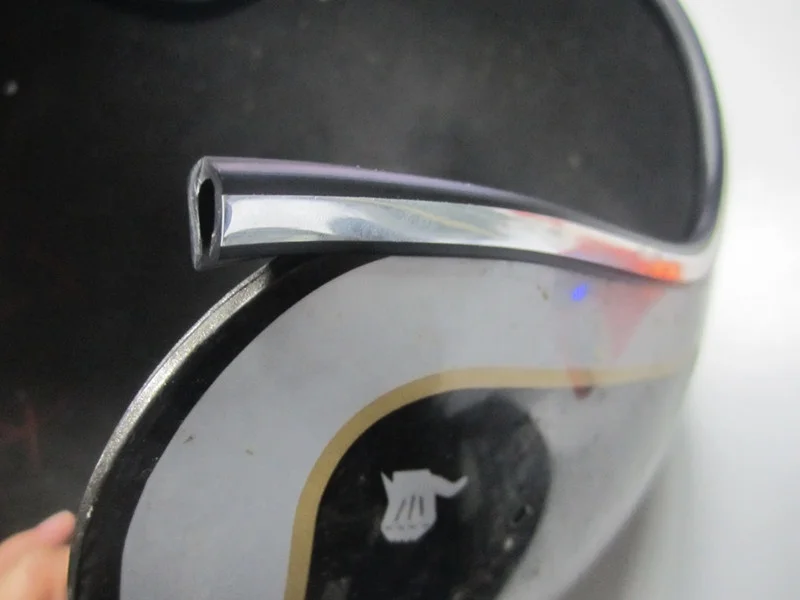

waterproof rubber seal strip

Jan . 25, 2025 05:06 Back to list

waterproof rubber seal strip

Waterproof rubber seal strips have emerged as a critical component in a multitude of applications, ensuring efficiency, longevity, and sustainability across various industries. As a seasoned expert in the field of sealing technologies, my insights are derived from decades of hands-on experience, comprehensive technical knowledge, and an unwavering commitment to quality and innovation.

What further strengthens the case for waterproof rubber seal strips is their adaptability and customization potential. Manufacturers offer these strips in various shapes, sizes, and profiles to meet specific sealing requirements. Custom solutions can be tailored to accommodate unique surface geometries, compressibility needs, and environmental conditions, ensuring a perfect fit and maximum efficiency. From a sustainability standpoint, the use of waterproof rubber seal strips aligns with global trends towards resource conservation and environmental stewardship. By enhancing the durability and performance of products, these strips contribute to the extended lifespan of applications, reducing the frequency of replacements and associated waste. Furthermore, advancements in rubber compounding have led to the development of eco-friendlier materials, lessening the environmental impact. Consumer trust in waterproof rubber seal strips is bolstered by rigorous testing and quality assurance measures adhered to by reputable manufacturers. Standards such as ISO 9001 ensure that products not only meet but often exceed industry benchmarks. Continuous research and development initiatives further support innovation in this domain, resulting in products that are safer, more reliable, and more efficient. For those seeking to implement waterproof rubber seal strips in their projects, it is essential to partner with manufacturers and suppliers who possess a proven track record of expertise and quality. Assessing the specific needs of your application, understanding the environmental conditions it will face, and aligning with industry experts will pave the way for successful sealing solutions. To conclude, waterproof rubber seal strips are more than mere accessories; they are pivotal elements that enhance reliability, performance, and sustainability across diverse applications. Their versatility, combined with advances in material science and engineering, positions them as indispensable tools in modern sealing technology. By investing in quality solutions and leveraging expert insights, businesses can confidently navigate the challenges of demanding environments while ensuring optimal protection and longevity.

What further strengthens the case for waterproof rubber seal strips is their adaptability and customization potential. Manufacturers offer these strips in various shapes, sizes, and profiles to meet specific sealing requirements. Custom solutions can be tailored to accommodate unique surface geometries, compressibility needs, and environmental conditions, ensuring a perfect fit and maximum efficiency. From a sustainability standpoint, the use of waterproof rubber seal strips aligns with global trends towards resource conservation and environmental stewardship. By enhancing the durability and performance of products, these strips contribute to the extended lifespan of applications, reducing the frequency of replacements and associated waste. Furthermore, advancements in rubber compounding have led to the development of eco-friendlier materials, lessening the environmental impact. Consumer trust in waterproof rubber seal strips is bolstered by rigorous testing and quality assurance measures adhered to by reputable manufacturers. Standards such as ISO 9001 ensure that products not only meet but often exceed industry benchmarks. Continuous research and development initiatives further support innovation in this domain, resulting in products that are safer, more reliable, and more efficient. For those seeking to implement waterproof rubber seal strips in their projects, it is essential to partner with manufacturers and suppliers who possess a proven track record of expertise and quality. Assessing the specific needs of your application, understanding the environmental conditions it will face, and aligning with industry experts will pave the way for successful sealing solutions. To conclude, waterproof rubber seal strips are more than mere accessories; they are pivotal elements that enhance reliability, performance, and sustainability across diverse applications. Their versatility, combined with advances in material science and engineering, positions them as indispensable tools in modern sealing technology. By investing in quality solutions and leveraging expert insights, businesses can confidently navigate the challenges of demanding environments while ensuring optimal protection and longevity.

Latest news

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025

-

Top Window Seal Strip Adhesive Companies - Durable & Reliable

NewsAug.18,2025