Acrylic Heat Bender Tool-Type A - Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Sep . 28, 2025 00:40 Back to list

Acrylic Heat Bender Tool-Type A - Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Introduction

The Acrylic Heat Bender Tool-Type A represents a significant advancement in acrylic fabrication technology. Designed for precision, durability, and ease of use, this tool has become a staple in industries ranging from lighting design to architectural modeling. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., a leading manufacturer in China, the tool combines cutting-edge engineering with practical functionality to meet the evolving demands of modern manufacturing.

Product Overview

The Acrylic Heat Bender Tool-Type A is a specialized device engineered to shape acrylic sheets with precision. Unlike traditional methods that rely on manual bending or heat guns, this tool utilizes controlled heat distribution and ergonomic design to ensure consistent results. The product is part of a broader range of acrylic-related solutions offered by Hebei Pulongte, which includes acrylic trim caps, lampshades, and industrial components.

Key Features and Technical Specifications

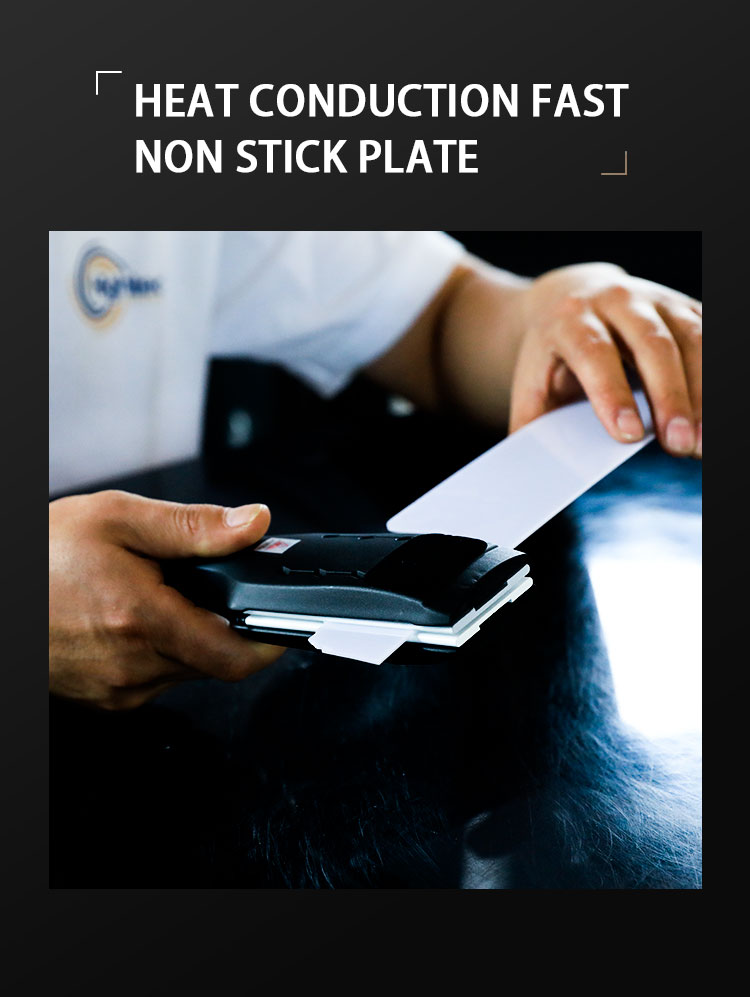

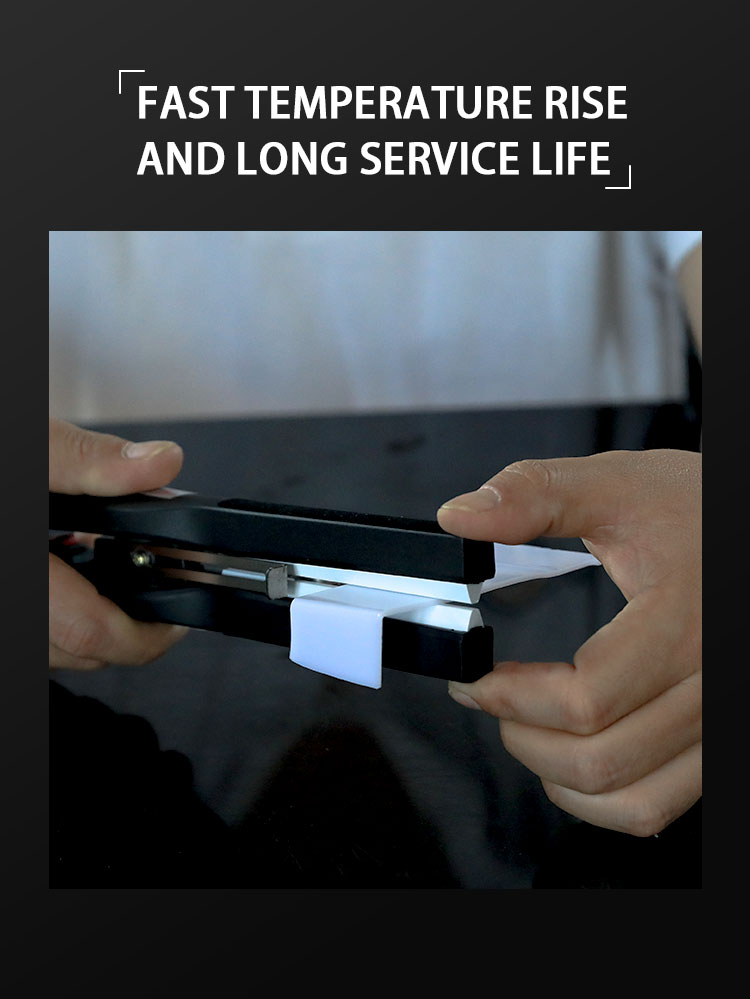

The Acrylic Heat Bender Tool-Type A is distinguished by its robust construction, user-friendly interface, and advanced thermal control systems. Below is a detailed specification table:

| Feature | Specification |

|---|---|

| Material | High-temperature resistant alloy with anti-slip grip |

| Heat Source | Electric heating element with adjustable temperature control |

| Dimensions | 300mm (L) x 150mm (W) x 100mm (H) |

| Weight | 1.2 kg |

| Power Supply | 220V/50Hz |

| Operating Temperature | 120°C–250°C |

| Compatibility | Acrylic sheets up to 5mm thickness |

Advantages and Unique Selling Points

The Acrylic Heat Bender Tool-Type A offers several advantages over conventional methods:

- Precision Control: The tool’s adjustable temperature settings allow for accurate bending of acrylic sheets without warping or cracking.

- Efficiency: Its electric heating system ensures rapid heat distribution, reducing production time and energy consumption.

- Ergonomic Design: The non-slip grip and lightweight structure minimize user fatigue during prolonged use.

- Durability: Constructed from high-temperature resistant alloys, the tool withstands frequent industrial use without degradation.

Applications and Industry Use Cases

The versatility of the Acrylic Heat Bender Tool-Type A makes it suitable for a wide range of applications:

1. Lighting Design

The tool is widely used to create custom acrylic lampshades and light covers, enabling designers to achieve intricate shapes and patterns. Its precision ensures uniform light diffusion and aesthetic appeal.

2. Architectural Modeling

Architects and engineers utilize the tool to fabricate acrylic prototypes for building facades, partitions, and decorative elements. The ability to bend acrylic sheets into complex geometries enhances the design flexibility of modern structures.

3. Industrial Manufacturing

Industries such as automotive and electronics rely on the tool for producing acrylic components like panels, enclosures, and insulation materials. Its durability and efficiency align with the demands of high-volume production.

4. Custom Fabrication

Small-scale manufacturers and DIY enthusiasts use the tool for creating personalized acrylic products, from signage to art installations. Its user-friendly interface makes it accessible to both professionals and hobbyists.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Hebei Pulongte Rubber and Plastic Technology Co., Ltd. is a leading manufacturer specializing in acrylic and plastic products. With over a decade of experience, the company has established itself as a trusted supplier of high-quality materials and tools for industrial and commercial applications. Their product range includes acrylic sheets, trim caps, and fabrication tools, all designed to meet international standards.

As a manufacturer based in China, Hebei Pulongte leverages advanced production technologies and rigorous quality control measures to ensure consistency and reliability. Their commitment to innovation is evident in the development of the Acrylic Heat Bender Tool-Type A, which addresses the growing need for precision in acrylic fabrication.

Industry Standards and Certifications

Hebei Pulongte adheres to international quality and safety standards, ensuring that the Acrylic Heat Bender Tool-Type A meets the requirements of global markets. While the context does not explicitly mention certifications, the company’s alignment with NIST (National Institute of Standards and Technology) principles underscores its commitment to precision and reliability. NIST, a U.S. government agency, plays a critical role in developing measurement standards that support technological innovation and industrial competitiveness.

According to NIST, "Standards and measurements are the foundation of modern technology, enabling industries to achieve consistency, safety, and efficiency" (NIST, 2025). Hebei Pulongte’s focus on precision engineering reflects this philosophy, ensuring that their products contribute to the advancement of manufacturing processes worldwide.

Customer Testimonials and Market Feedback

Users of the Acrylic Heat Bender Tool-Type A have praised its performance and reliability. One customer noted, "This tool has significantly improved our production efficiency. The temperature control is precise, and the design is intuitive." Another user highlighted its durability: "After months of use, the tool shows no signs of wear, making it a worthwhile investment."

Market feedback also emphasizes the tool’s versatility. "Whether for small-scale projects or large manufacturing runs, the Acrylic Heat Bender Tool-Type A delivers consistent results," said a lighting designer from Germany.

Conclusion

The Acrylic Heat Bender Tool-Type A exemplifies the synergy between innovation and practicality in acrylic fabrication. Its advanced features, combined with the expertise of Hebei Pulongte Rubber and Plastic Technology Co., Ltd., make it a valuable asset for industries seeking precision and efficiency. As the demand for custom acrylic solutions continues to grow, tools like this will play a pivotal role in shaping the future of manufacturing.

For more information about the product, visit the official product page or explore the company’s website for additional offerings.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025