Acrylic Heat Bender Tool-Type A - Hebei Pulongte Rubber and Plastic Technology Co., Ltd.|Precision Engineering,Durable Construction

Sep . 08, 2025 23:20 Back to list

Acrylic Heat Bender Tool-Type A - Hebei Pulongte Rubber and Plastic Technology Co., Ltd.|Precision Engineering,Durable Construction

Introduction

The Acrylic Heat Bender Tool-Type A represents a significant advancement in the field of acrylic material processing. Designed for precision and efficiency, this tool enables users to bend and shape acrylic sheets with ease, making it an essential asset for manufacturers, artisans, and DIY enthusiasts. This article delves into the product's features, advantages, technical specifications, and the company behind it, while also highlighting its relevance in the context of industry standards and innovation.

Product Overview

The Acrylic Heat Bender Tool-Type A is a specialized device engineered to simplify the process of bending acrylic sheets. Its design focuses on delivering consistent results, whether for industrial applications or creative projects. The tool's versatility allows it to handle various acrylic thicknesses, making it suitable for a wide range of tasks. By leveraging heat and pressure, the tool ensures that the material retains its structural integrity while achieving the desired shape.

Key Features and Advantages

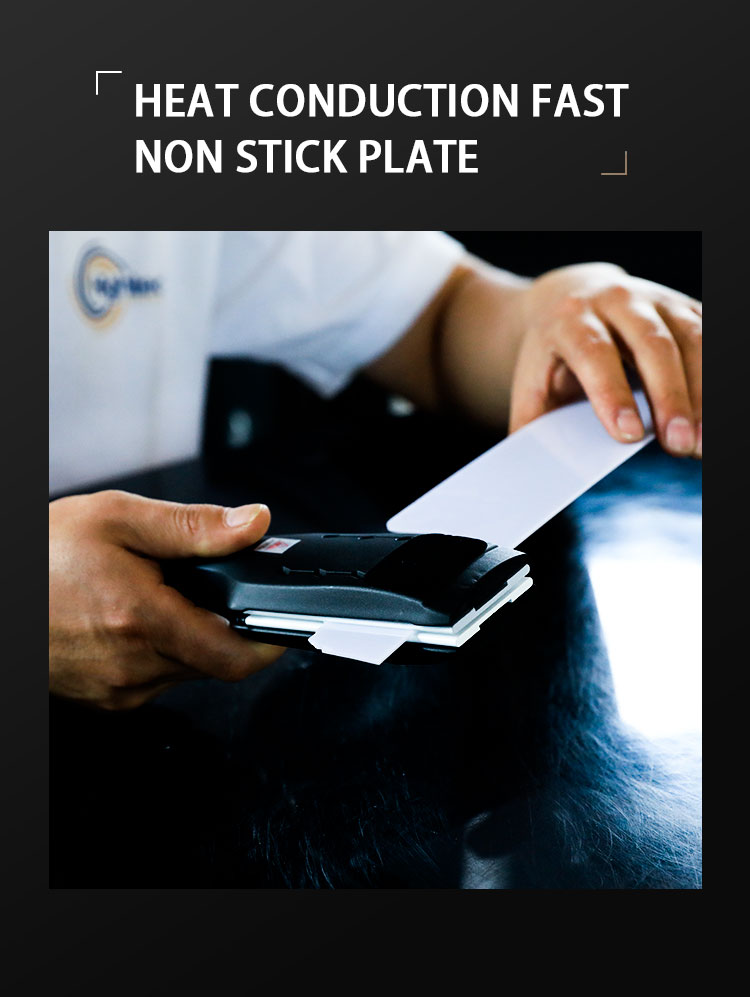

1. Precision Engineering

One of the standout features of the Acrylic Heat Bender Tool-Type A is its precision engineering. The tool is equipped with adjustable temperature controls and pressure settings, allowing users to customize the bending process according to the specific requirements of their project. This level of control ensures that even complex shapes can be achieved with minimal effort.

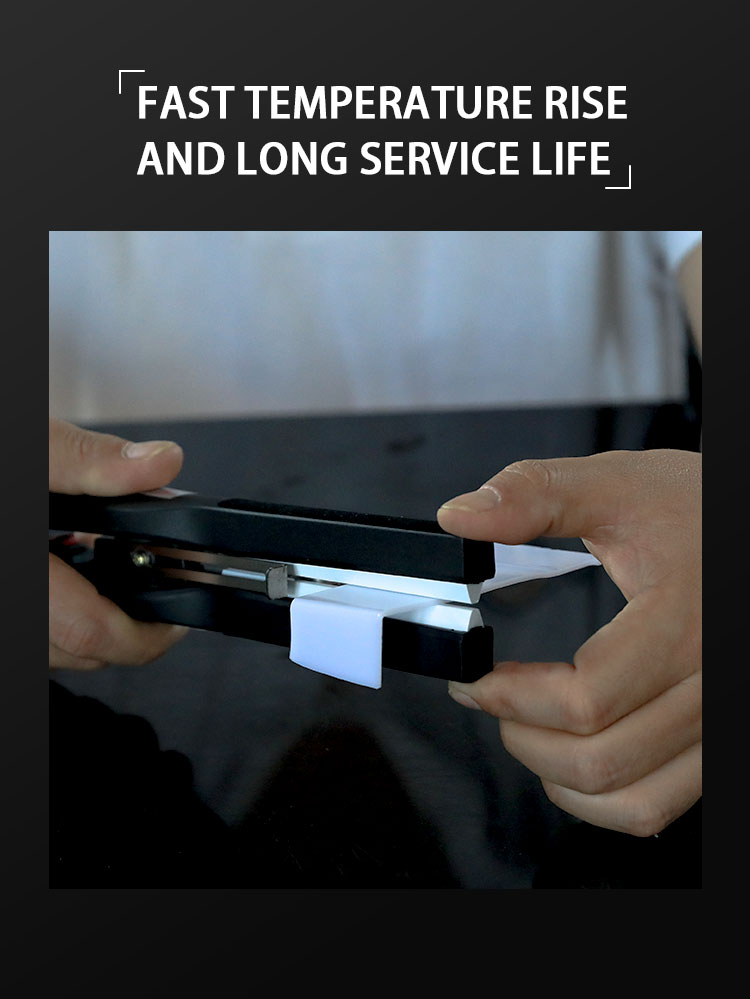

2. Durable Construction

Constructed from high-quality materials, the tool is designed to withstand the rigors of frequent use. Its robust build ensures longevity, making it a reliable investment for both small-scale and large-scale operations. The tool's durability is further enhanced by its heat-resistant components, which can withstand the high temperatures required for effective acrylic bending.

3. User-Friendly Design

The Acrylic Heat Bender Tool-Type A is designed with the user in mind. Its intuitive interface and ergonomic handle make it easy to operate, even for those who are new to acrylic crafting. The tool's compact size also contributes to its portability, allowing users to work in various settings without the need for a dedicated workspace.

4. Versatility

Whether you're working on a simple project or a complex design, the Acrylic Heat Bender Tool-Type A offers versatility that meets diverse needs. It can be used to create a variety of shapes, from basic curves to intricate designs, making it an indispensable tool for professionals and hobbyists alike.

Technical Specifications

| Feature | Details |

|---|---|

| Material | Durable aluminum alloy with heat-resistant components |

| Temperature Range | 150°C - 250°C (302°F - 482°F) |

| Dimensions | 450mm x 200mm x 150mm (17.7in x 7.9in x 5.9in) |

| Weight | 2.5kg (5.5lbs) |

| Power Supply | 110V/220V AC, 50/60Hz |

| Compatibility | Acrylic sheets up to 5mm (0.2in) thickness |

Applications and Use Cases

The Acrylic Heat Bender Tool-Type A finds application in various industries, including manufacturing, interior design, and custom fabrication. Here are some specific use cases:

- Custom Furniture Manufacturing: The tool is ideal for creating curved acrylic components for furniture, such as table tops, shelves, and decorative elements.

- Lighting Design: Artisans and designers use the tool to craft unique lampshades and light covers, enhancing the aesthetic appeal of their creations.

- Signage and Displays: The tool's precision allows for the production of custom acrylic signs and display cases, which are widely used in retail and advertising.

- DIY Projects: Hobbyists can utilize the tool to create personalized items, from acrylic frames to decorative pieces, expanding their creative possibilities.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

The Acrylic Heat Bender Tool-Type A is produced by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., a reputable manufacturer based in Hebei, China. With a focus on innovation and quality, the company has established itself as a leader in the production of rubber and plastic products. Their commitment to excellence is reflected in the design and functionality of the Acrylic Heat Bender Tool-Type A, which combines advanced technology with practical application.

Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has a strong presence in the global market, supplying products to various industries. Their expertise in material science and manufacturing processes ensures that their tools meet the highest standards of performance and reliability. The company's dedication to customer satisfaction is evident in their comprehensive support and after-sales services, making them a trusted partner for businesses and individuals alike.

Industry Standards and Innovation

The development of the Acrylic Heat Bender Tool-Type A aligns with the principles of innovation and adherence to industry standards. As highlighted by the National Institute of Standards and Technology (NIST), the importance of precise measurements and standardized processes cannot be overstated in manufacturing. NIST's role in advancing technology and supporting U.S. manufacturing underscores the significance of tools like the Acrylic Heat Bender Tool-Type A in ensuring quality and consistency in production.

According to NIST, "Standards and measurements are the foundation of technological advancement, enabling industries to innovate while maintaining safety and efficiency." The Acrylic Heat Bender Tool-Type A exemplifies this principle by providing a reliable solution for acrylic shaping, thereby contributing to the broader goal of enhancing manufacturing practices.

Furthermore, the tool's design reflects a commitment to sustainability, as it minimizes material waste during the bending process. This aligns with the growing emphasis on eco-friendly manufacturing practices, which is a key focus area for many industries today.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to the power of innovation in the field of acrylic processing. Its precision, durability, and versatility make it an invaluable tool for professionals and enthusiasts alike. By partnering with Hebei Pulongte Rubber and Plastic Technology Co., Ltd., users gain access to a product that not only meets but exceeds industry standards.

As the demand for high-quality acrylic products continues to grow, the Acrylic Heat Bender Tool-Type A stands out as a reliable solution for achieving exceptional results. Its ability to streamline the bending process ensures that users can focus on creativity and efficiency, ultimately enhancing their productivity and satisfaction.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025